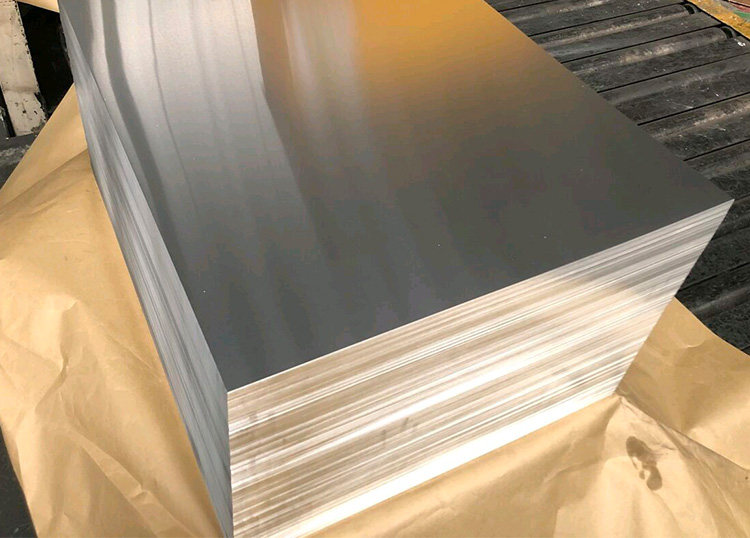

Painted aluminum sheet metal offers a unique combination of durability, aesthetics, and formability. This lightweight material finds itself in a wide range of applications, from building facades to household appliances. 3105 painted aluminum sheets are one of the representatives. This article explores the world of painted aluminum sheets, delving into its various finishes and applications.

What are the Types of Color and Surface Finishes?

Painted aluminum sheets can come in various types of colors and surface finishes, offering versatility and aesthetic options for different applications. Some common types include:

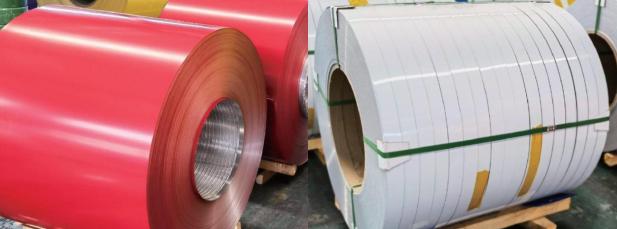

- Solid Colors: These are single, uniform colors applied to the aluminum sheet surface, from classic shades like black and white to vibrant blues and fiery reds. Solid colors offer a clean and consistent appearance.

- Metallic Finishes: Metallic finishes incorporate metallic flakes or pigments into the paint, creating a reflective and lustrous appearance. This finish can mimic the look of metals such as silver, gold, bronze, or copper.

- Pearlescent Finishes: Pearlescent finishes contain special pigments that create a shimmering effect, resembling the iridescence of pearls. These finishes often exhibit a subtle color shift depending on the viewing angle and lighting conditions.

- Textured Finishes: Textured finishes add depth and dimension to the surface of the painted aluminum sheet. Texturing can help to hide scratches and imperfections, and it can also add a unique visual element to the sheet. Common textured finishes include wood grain, leather, hammered, orange peel, or even stucco.

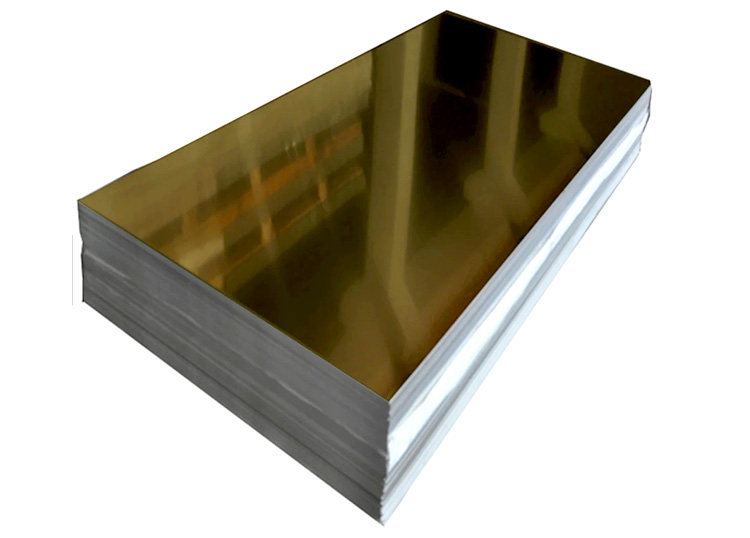

- Glossy Finishes: Glossy finishes have a smooth and reflective surface, offering a polished appearance. These finishes are characterized by their high gloss and shine, adding a sleek and modern look to the aluminum sheet.

- Matte Finishes: Matte finishes have a non-reflective surface with a low gloss level. They provide a more subdued and understated appearance compared to glossy finishes, making them suitable for applications where glare reduction is desired.

- Satin Finishes: Satin finishes offer a balance between matte and glossy surfaces, featuring a smooth texture with a subtle sheen. This finish provides a refined and elegant appearance while minimizing glare.

These are some of the common types of color and surface finishes available for painted aluminum sheets. The choice of finish depends on factors such as aesthetic preferences, application requirements, durability, and environmental conditions.

Techniques of Painting Aluminum Sheets

Painting aluminum sheets can be done using various techniques, depending on factors such as the desired finish, application requirements, and available equipment. Some common techniques for painting aluminum sheets include:

- Spray Painting: Spray painting is a widely used technique for applying paint to aluminum sheets. It involves using a spray gun to atomize the paint into fine droplets, which are then evenly distributed onto the surface of the aluminum sheet. Spray painting allows for precise control over the thickness and coverage of the paint, resulting in a smooth and uniform finish.

- Roller Painting: Roller painting involves using a paint roller to apply paint to the surface of the aluminum sheet. This technique is commonly used for painting large surface areas or areas with intricate details. Roller painting can provide good coverage and is relatively easy to perform, but it may not result in as smooth a finish as spray painting.

- Brush Painting: Brush painting is a traditional technique that involves applying paint to the aluminum sheet using a paintbrush. This technique allows for greater control over the application of paint and is suitable for smaller surface areas or areas with irregular shapes. Brush painting may require multiple coats to achieve adequate coverage and may result in a slightly textured finish.

- Dip Coating: Dip coating involves immersing the aluminum sheet into a bath of paint or coating material, allowing the paint to adhere to the surface. This technique is often used for applying thin, uniform coatings to aluminum sheets and is suitable for mass production applications. Dip coating can result in a smooth and consistent finish but may require additional steps such as drying and curing.

- Powder Coating: Powder coating is a technique that involves electrostatically applying dry powder paint to the surface of the aluminum sheet, followed by curing in an oven to melt and fuse the powder into a continuous coating. Powder coating offers excellent durability, resistance to chipping and scratching, and a wide range of color options. It is commonly used for both decorative and protective coatings on aluminum sheets.

- Anodizing: Anodizing is a specialized surface treatment technique for aluminum that involves creating a durable oxide layer on the surface of the aluminum sheet through an electrolytic process. While not technically painting, anodizing can alter the appearance of aluminum sheets by providing a decorative finish in various colors while also enhancing corrosion resistance and durability.

The choice of painting technique for aluminum sheets depends on factors such as the desired finish, application requirements, production volume, and available equipment and resources. Each technique has its advantages and limitations, so it’s essential to consider these factors carefully when selecting the most suitable painting technique.

Common Paints in Painting Aluminum Sheet

When painting aluminum sheets, various types of paints can be used depending on the specific requirements of the application. Some common types of paints used for painting aluminum sheets include:

- Polyester Paints: Polyester paints are one of the most commonly used types of paints for coating aluminum sheets. They offer good durability, weather resistance, and color retention. Polyester paints aluminum are available in a wide range of colors and finishes, making them suitable for various applications.

- PVDF (Polyvinylidene Fluoride) Paints: PVDF paints, also known as fluoropolymer paints, are highly durable and weather-resistant coatings commonly used for architectural applications. PVDF paints aluminum offer excellent resistance to fading, chalking, and chemical exposure, making them suitable for exterior use in harsh environments.

- Epoxy Paints: Epoxy paints provide excellent adhesion and corrosion resistance, making them suitable for applications where aluminum sheets are exposed to corrosive environments such as chemical plants or marine applications. Epoxy paints are available in various colors and can be applied as a primer or topcoat.

- Acrylic Paints: Acrylic paints offer good durability and weather resistance, along with fast drying times. They are often used for indoor applications or outdoor applications where extended exposure to harsh weather conditions is not a concern. Acrylic paints are available in a wide range of colors and can be easily applied by brush, roller, or spray gun.

- Polyurethane Paints: Polyurethane paints provide excellent durability, chemical resistance, and UV resistance, making them suitable for outdoor applications such as automotive coatings or architectural applications. Polyurethane paints offer a high-gloss finish and are available in various colors and formulations.

- Alkyd Paints: Alkyd paints, also known as oil-based paints, offer good adhesion and durability. They are commonly used for industrial applications or DIY projects where a durable and cost-effective coating is required. Alkyd paints can be applied to aluminum sheets using a brush, roller, or spray gun.

- Water-based Paints: Water-based paints, also known as latex paints, are environmentally friendly and low in volatile organic compounds (VOCs). They offer good adhesion and durability for indoor applications and are available in a wide range of colors and finishes. Water-based paints are easy to clean up with water and are suitable for DIY projects or commercial applications.

These are some of the common types of paints used for painting aluminum sheets. The choice of paint depends on factors such as the application requirements, desired finish, environmental conditions, and budget.

What are the Advantages and Applications of Painted Aluminum Sheets?

Painted aluminum sheets offer several advantages and find applications across various industries due to their unique properties.

Advantages of Painted Aluminum Sheets

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing excellent resistance to corrosion. When painted, this resistance is further enhanced, making painted aluminum sheets suitable for outdoor applications.

- Lightweight: Aluminum is lightweight compared to other metals like steel, making painted aluminum sheets easier to handle and transport.

- Durability: Painting aluminum adds an additional layer of protection, enhancing its durability and extending its lifespan.

- Versatility: Painted aluminum sheets come in various colors, finishes, and textures, providing designers and architects with versatility in aesthetics.

- Recyclability: Aluminum is highly recyclable, and painted aluminum sheets can be recycled without losing their properties, making them environmentally friendly.

- Ease of Fabrication: Aluminum is easily formed, cut, and shaped, allowing for various fabrication techniques, such as bending, punching, and welding.

- Cost-Effective: While aluminum initially might have a higher cost compared to some other materials, its long-term durability and low maintenance requirements can make it cost-effective over its lifespan.

Applications of Painted Aluminum Sheets

This table shows the advantages of painted aluminum sheets in various applications.

| Application | Description | Advantages |

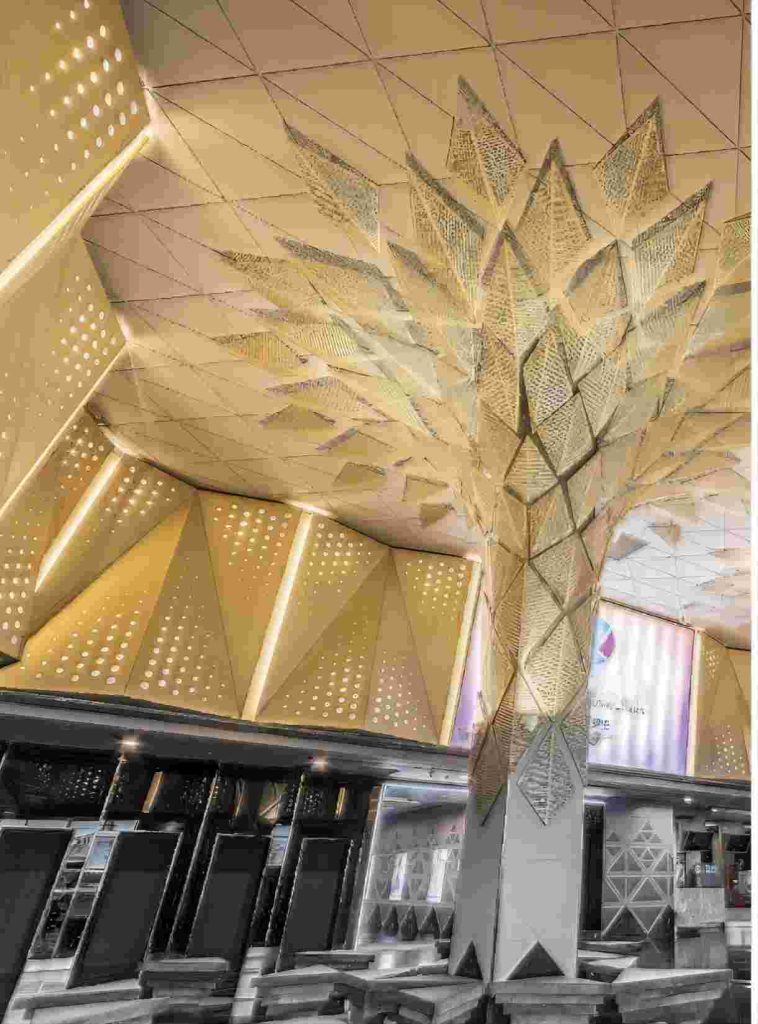

| Building and Construction | Painted aluminum sheets are commonly used in the construction industry for roofing, siding, facades, and decorative elements. | Lightweight, corrosion-resistant, durable, aesthetically pleasing. |

| Signage and Displays | Popular for outdoor signage and indoor displays due to color retention and resistance to fading. | Maintains color, resistant to fading, durable. |

| Appliances | Used in the manufacturing of refrigerators, ovens, and air conditioners for decorative purposes and corrosion protection. | Decorative, corrosion-resistant, protects against scratches. |

| Marine Applications | Used in boat hulls, docks, and marine equipment due to corrosion resistance, especially in saltwater environments. | Corrosion-resistant, lightweight, durable. |

| Consumer Goods | Utilized in furniture, household items, and electronics casings for decorative purposes and protection against scratches. | Decorative, protects against scratches, lightweight. |

| Automotive Industry | Used for body panels, trims, and decorative elements in vehicles for enhanced appearance and fuel efficiency. | Lightweight, corrosion-resistant, durable, and aesthetically pleasing. |

Overall, painted aluminum sheets offer a combination of durability, versatility, and aesthetic appeal, making them suitable for a wide range of applications across different industries.

Conclusion

Painted aluminum sheet transcends its utilitarian purpose and becomes a versatile design element. Its strength, light weight, and diverse color and texture options make it a favorite material for architects, builders, product designers, and anyone looking for a combination of functionality and aesthetics. With its ever-evolving finishes and applications, the painted aluminum sheet is sure to remain a prominent player in the world of materials for years to come.