Rising Aluminum Prices in 2026: Causes, Supply Shortage, and Industry Impact

Why 2026 Is a Turning Point for the Global Aluminum Market? Global aluminum market has been defined by cycles for many years. Periods of high prices triggered capacity expansion, which was eventually…

High-Efficiency Aluminum Microchannel Tube Solutions for Modern HVAC

At the moment, the global Heating, Ventilation, Air-Conditioning, and Refrigeration (HVAC-R) industry is undergoing radical changes. It accredits the effective policies that foster environmental conservation, the arising necessity for foreign…

Precision Aluminum Extrusion Tubes: Why High-Tolerance Tubing Is Powering EVs and AI Data Centers

The future of the global aluminum markets is not defined by total capacity but rather by the precision and quality strategy. Previously, the market was characterized by construction profiles and…

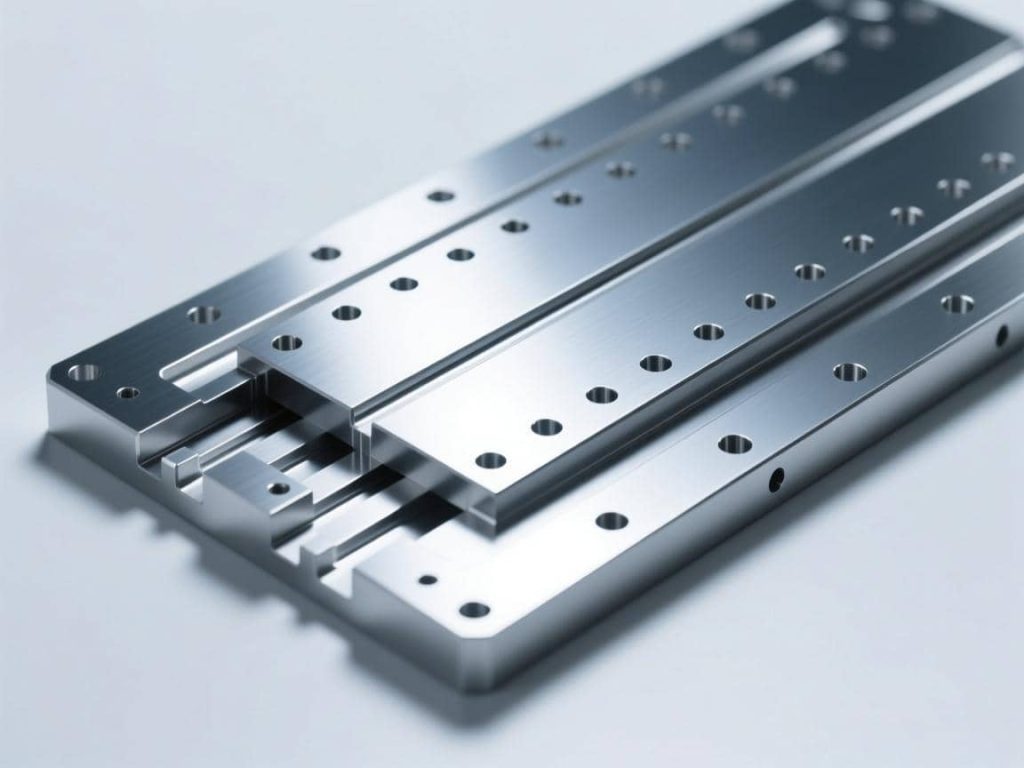

MIC 6 Aluminum Plate: Why It’s the Best Aluminum Tooling Plate for Precision Machining

Precision manufacturing requires materials with excellent dimensional stability, flatness, and low internal stress. Thus, in the accuracy-controlled areas like CNC machining, it is even the slightest material distortion may cause…

Insulated Aluminium Roof Panels vs Standard Aluminium Panels – Which Is Best for Your Building?

The prime driver in modern housing is energy efficiency. There is no better alternative to enhancing the efficiency of buildings than employing high-quality roofing material. Of all the high-efficiency materials…

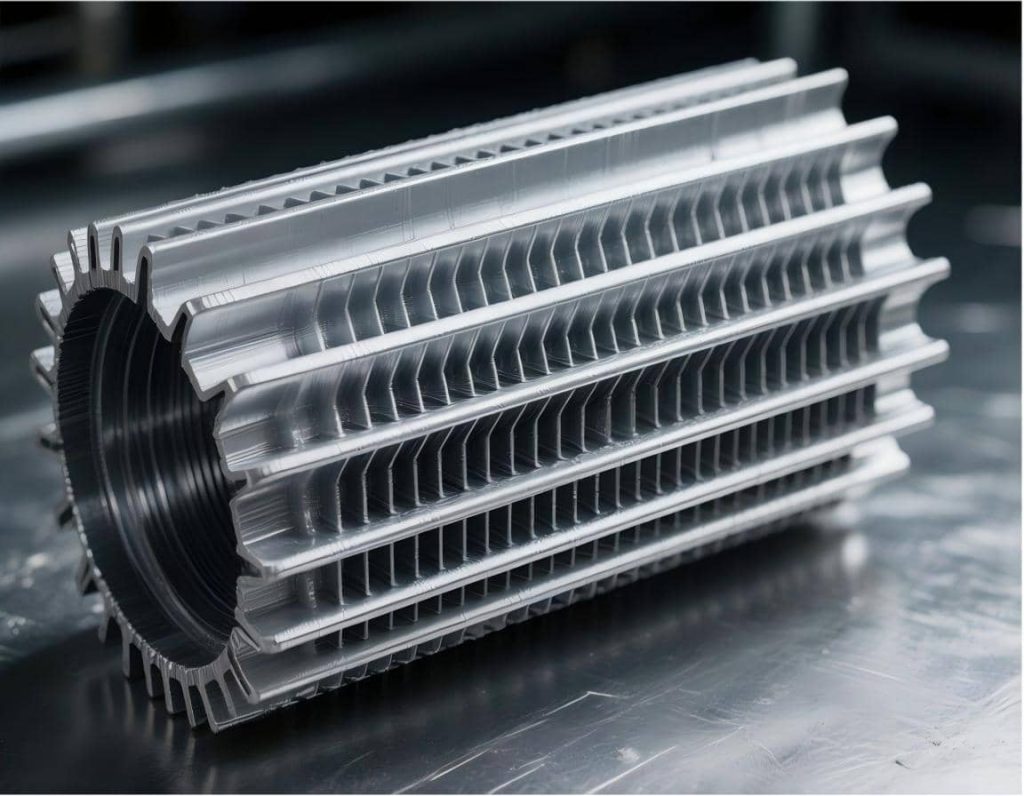

Aluminum Finned Tubes vs Micro-channel Tubes, How to Select for Cooling Systems?

If you think about heat exchangers, automotive air conditioning, commercial HVAC systems, and industrial cooling equipment, you will think about aluminum finned tubes and aluminum micro-channel tubes. Both technologies have aluminum, which is…

Color Coated Aluminum Coil: Applications, Technologies, and Sustainability

Urbanisation, new infrastructure, and further advances in coating technology galvanise global markets and heighten consumer interest in versatile, durable, and lightweight materials. The global market for color coated aluminium coils is projected…

Is It Illegal to Put Aluminum Foil on Windows?

Have you ever heard why some people put aluminum foil on their windows? Some people say it’s to help make the home feel cozier, and help reduce heat and increase…

Applications and Advantages of Aluminum U-Profiles in Renewable Energy Structures

To address climate change and enhance energy security, the world is transitioning towards sustainable energy, and renewable energy has become the top priority in infrastructure construction. With the continuous advancement…

A Guide to Aluminum MIG Welding Wire Selection and Application

Welding aluminium and welding steel are completely different things. It’s not just a matter of how you do it. Metals themselves behave differently due to their special physical and chemical…

How 6061 T6 Rectangular Tube Powers the New Energy Revolution?

In a future filled with tech, one can picture a vivid landscape of interwoven advanced solar panels following the sun, electric cars cruising smoothly on the busy highways, and oversized,…

Why Are Tapered Aluminum Tubes a Preferred Choice for Outdoor Equipment Applications?

Outdoor gear made from the tapered aluminum tube is changing the industry as the demand for lightweight and high-performance products continues to rise. Thinner designs improve the stability and strength of…