6061 Aluminum Bars: Reliable Material for High-Stress Applications

Aluminum alloy 6061 stands out as one of the most versatile and widely used aluminum alloys in the engineering world. Its exceptional combination of strength, corrosion resistance, machinability, and weldability…

Choosing the Right Marine Aluminium: 5052 vs. 5083 vs. 5086 Alloys Comparison

The unforgiving marine environment demands materials that can withstand constant exposure to saltwater, humidity, and the stresses of waves and impacts. Among the various materials used in shipbuilding and marine…

Aluminum Panels for Interior and Exterior Walls: How to Choose?

Aluminum panels have become a preferred choice in modern construction for both interior and exterior walls due to their durability, aesthetic appeal, and versatility. However, selecting the right aluminum panel requires…

6061 t6 vs 7075 t6 Heat Treatment: What Are the Differences?

Aluminum alloys are widely used across multiple industries due to their favorable strength-to-weight ratio, excellent corrosion resistance, and high workability. From aerospace and automotive applications to consumer electronics and structural components,…

How to Select the Right Aluminum Sheet for Your Trailer

Trailers serve a multitude of purposes, from hauling cargo to providing mobile living spaces. The skin of your trailer plays a crucial role in its durability, functionality, and aesthetics. Aluminum…

Aluminum vs. Carbon Fiber: The Strength Debate and Application Choices

Aluminum and carbon fiber are two widely used materials in modern industries, each offering unique properties that make them suitable for various applications. Aluminum, a lightweight metal known for its…

Expert Techniques for Heat Sealing Aluminum Foil to Perfection

Heat sealing aluminum foil is a critical process across numerous industries, from food packaging to pharmaceuticals. Achieving a perfect seal ensures product integrity, extends shelf life, and maintains critical barriers against…

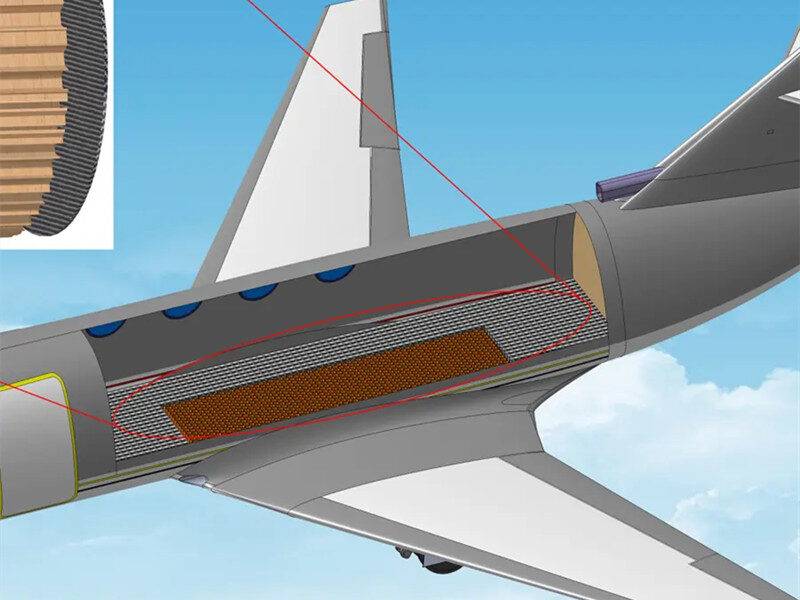

How is Aluminum Honeycomb Core Made?

Aluminum honeycomb core is a lightweight, high-strength material widely used in industries such as aerospace, construction, and transportation. This material consists of thin aluminum foil arranged in a hexagonal pattern, mimicking…

Stronger, Lighter, Greener: Aluminium in Wind Turbine Blades

The global push for sustainable energy has placed wind power at the forefront of renewable technologies. Wind turbines, towering structures harnessing the kinetic energy of wind, are pivotal in this…

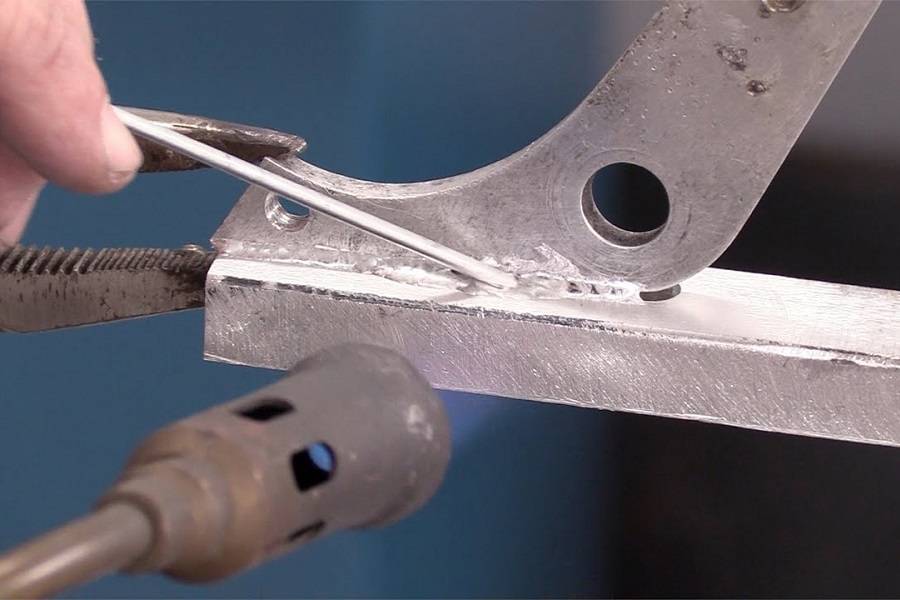

Aluminium Flux Paste and Solder Paste in Soldering: How to Choose and Use

Soldering aluminium presents unique challenges due to the presence of a natural oxide layer that inhibits proper bonding between the metal and solder. Traditional soldering techniques used for copper and other…

Top Industrial Uses of Waterproof Aluminium Tape

Waterproof aluminium tape is a versatile and indispensable material across various industries. Known for its durability and resistance to environmental factors, this tape has become a go-to solution for sealing, repairing,…

4 Applications of Heavy-Duty Aluminum Foil in Aerospace

The aerospace industry demands materials that can withstand extreme conditions, from the vacuum of space to the intense heat of atmospheric reentry. Heavy-duty aluminum foil has emerged as an indispensable material,…