Standard and Custom Aluminum Box Profiles: Common Sizes and How to Choose

Aluminum box profiles are an essential element of many structural, architectural and industrial applications. Their hollow rectangular or square cross section provides strong yet lightweight corrosion-resistant support frameworks and enclosures. As…

Aluminum vs. Steel: Which is the Better Exhaust Pipe Material?

Your motorcycle or car’s exhaust system does more than provide a route for exhaust gases to escape; it also impacts the vehicle’s performance, the sound it produces, and the vehicle’s…

What to Look for in Aluminum Blocks for CNC?

The overall effectiveness of CNC machining ultimately relies on more than programmable tool paths or veteran machinists—it turns on the integrity of the raw stock itself. For anyone responsible for…

Plastic, PVC, and Copper: Which Coated Aluminium Wire Types Suit Your Needs?

Due to the application of coatings, aluminum wires acquire new advantages and slowly become bare aluminum wires. Coating of plastic, PVC, and copper makes the wires easier to use in…

3 Key Parameters to Choose Waterproof Aluminum Foil Tape for Industrial Use

The Waterproof aluminum foil tape is a very important item in many industries because of its reliable function in sealing, insulation and repair. The industrial sectors have a variety of tape applications,…

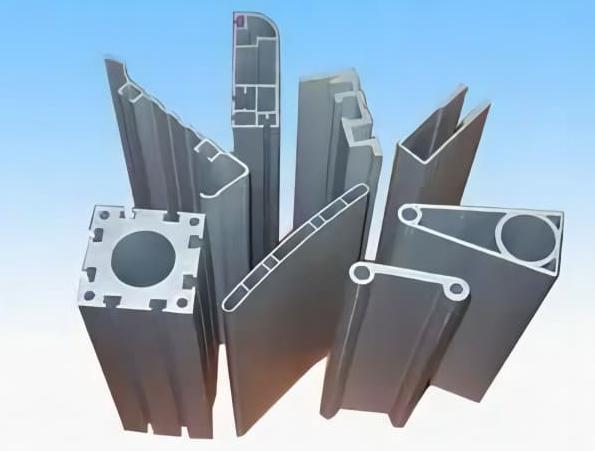

Choosing the Right Aluminum Extrusion Shape for Your Engineering Needs

Aluminum extrusions play a vital role in modern engineering, providing versatile solutions for diverse industries like construction, transportation, and electronics. The variety of available profiles, from standard designs to custom configurations,…

How Aluminum Roof Coatings Reduce Cooling Costs

Aluminum roofs are highly valued for their durability, lightweight structure, and corrosion resistance. However, as summer temperatures rise, so often do our energy bills. Homeowners and building managers constantly seek effective…

What is Battery Aluminum Foil? Types and Applications

In the ever-evolving field of energy storage, the materials used in battery construction play a crucial role in determining performance, longevity, and safety. Among these materials, aluminum foil for battery applications…

How to Clean and Maintain the Surface Finish of Aluminum Diamond Plates?

Diamond-cut aluminum plates provide a cost-effective and attractive surface suitable for a variety of uses such as trailer trim and garage flooring to building materials and tools. Its raised diamond-patterned finish…

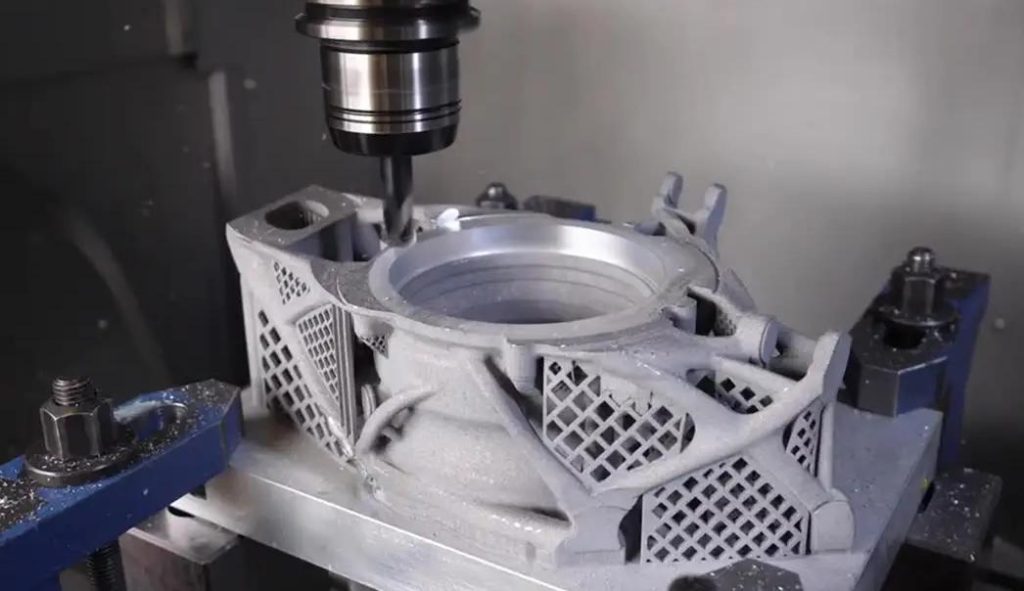

Selecting the Right Aluminum Additive Manufacturing Alloy for Industrial Applications

Have you ever thought of turning your designs into real metal components with amazing accuracy? Welcome to the thrilling world of aluminum additive manufacturing! This cutting-edge technology is often known…

Aluminum TIG Welding Cracks: What Causes Them and How to Prevent

Welding, a fundamental process in fabrication and manufacturing, plays a crucial role in joining metallic components with precision and strength. Among the various welding techniques available, Tungsten Inert Gas (TIG)…

Why is Aluminum Used in Food Containers? 5 Key Reasons

The selection of appropriate food containers is paramount in ensuring food safety, maintaining quality, and facilitating convenient handling. Among the myriad of materials available, aluminum stands out as a consistently…