Top Industrial Uses of Waterproof Aluminium Tape

Waterproof aluminium tape is a versatile and indispensable material across various industries. Known for its durability and resistance to environmental factors, this tape has become a go-to solution for sealing, repairing,…

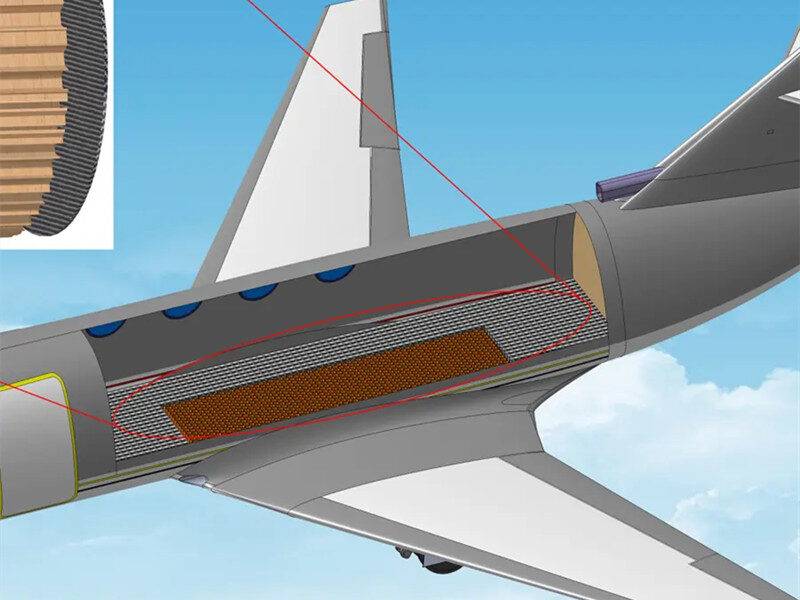

4 Applications of Heavy-Duty Aluminum Foil in Aerospace

The aerospace industry demands materials that can withstand extreme conditions, from the vacuum of space to the intense heat of atmospheric reentry. Heavy-duty aluminum foil has emerged as an indispensable material,…

Aluminum Sheet Cutting: Methods, Applications, and Considerations

Aluminum, renowned for its lightweight, corrosion-resistant, and versatile properties, finds extensive applications across numerous industries. The ability to precisely cut aluminum sheets is crucial for manufacturing components with accurate dimensions…

Cooking Food in Aluminum Foil: What You Need to Know

Cooking food in aluminum foil is a popular technique for its convenience, versatility, and ease of cleanup. Whether you’re preparing a meal at home, grilling outdoors, or camping, aluminum foil can…

How Aluminum Pipe Connection Methods Affect the Performance of the Piping System

Aluminum piping systems have surged in popularity across diverse industries, from compressed air distribution in manufacturing to HVAC systems in commercial buildings. Their lightweight nature, corrosion resistance, and ease of handling…

How to Cast Aluminum Parts: A Step-by-Step Guide to the Casting Process

Aluminum casting is an essential manufacturing process used across various industries, including automotive, aerospace, construction, and electronics. The ability to produce complex and lightweight parts with excellent mechanical properties makes aluminum…

What Are the Uses of Aluminum in the Refrigeration Industry?

Aluminum, the second most widely used metal globally, plays a pivotal role in the refrigeration industry due to its lightweight nature, corrosion resistance, and high thermal conductivity. From household refrigerators…

Smart Choices for Household Aluminum Foil: From Thickness, Size, to Eco-Friendly

Aluminum foil is a versatile household material widely used for food packaging, baking, grilling, and storage due to its excellent thermal conductivity, sealing properties, and durability. However, with a variety of…

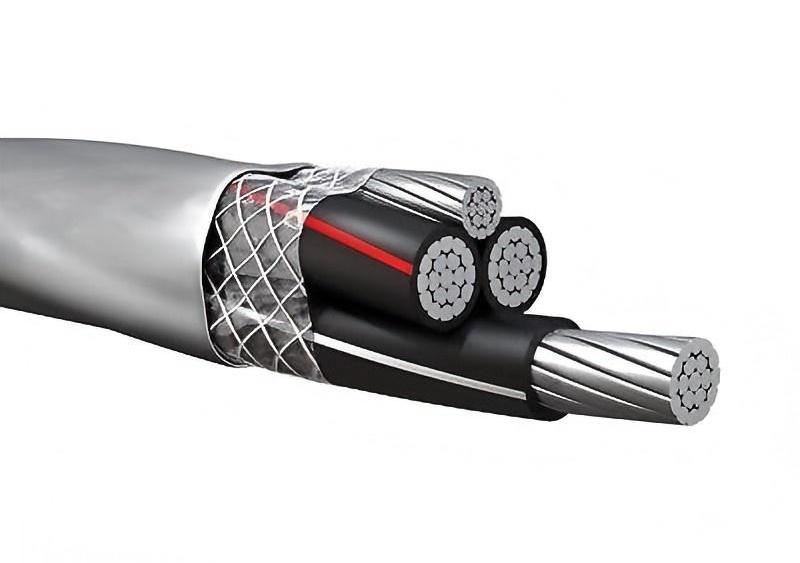

Electrical Properties of Aluminum and Its Industrial Applications

Aluminum is a highly versatile and abundant metal, playing a pivotal role in various industries due to its unique combination of properties. Beyond its lightweight nature and corrosion resistance, its electrical properties stand…

How Aluminum Powder is Changing Additive Manufacturing

Additive manufacturing(AM), commonly known as 3D printing, is transitioning from prototyping to industrial production, driven by the revolutionary adoption of aluminum powder. With its low density, high strength-to-weight ratio, and excellent…

Structural Aluminum Tubes: Shapes, Connections and Inspections

Structural aluminum tubes, prized for their lightweight nature, high strength, and corrosion resistance, find extensive applications across diverse sectors including construction, machinery, and aerospace. As industrial demands diversify and technology…

Decoding Aluminum Wire Specifications: Understanding the Numbers and Uses

Aluminum wire plays a crucial role in electrical power transmission due to its lightweight nature, cost-effectiveness, and conductivity. As a widely used conductor, aluminum wire is found in residential, commercial,…