What can aluminum foil do in the wilderness?

Aluminum foil is well known as a good tool for baking potatoes and blocking alien mind probes, but it is seldom be known as a pretty handy tool in real…

Does The Aluminum Foil Roll Have An Expiration Date?

It is being frequently asked online for the question that if Aluminum Foil Roll have an expiration date, and the answers are various. Some of them think that the date…

Why Do Manufacturers in These Industries Prefer to Choose Aluminium Tubes?

Aluminium tube is an extruded material composed of aluminium alloy, usually described as an architectural or structural alloy, suitable for internal and external architectural applications. They have high corrosion resistance and…

Will the Shinny Side of Aluminum Foil Affect Convection?

Aluminum foil also named tin foil, is just as thin as a paper, a shinny sheet that is made of aluminum metal. The main production process is by rolling large slabs…

What are the processing techniques of aluminium alloy?

Aluminium alloy is a commonly used industrial material. It is very light and weighs about one-third of the same volume of copper or steel. It is corrosion-resistant, is an excellent…

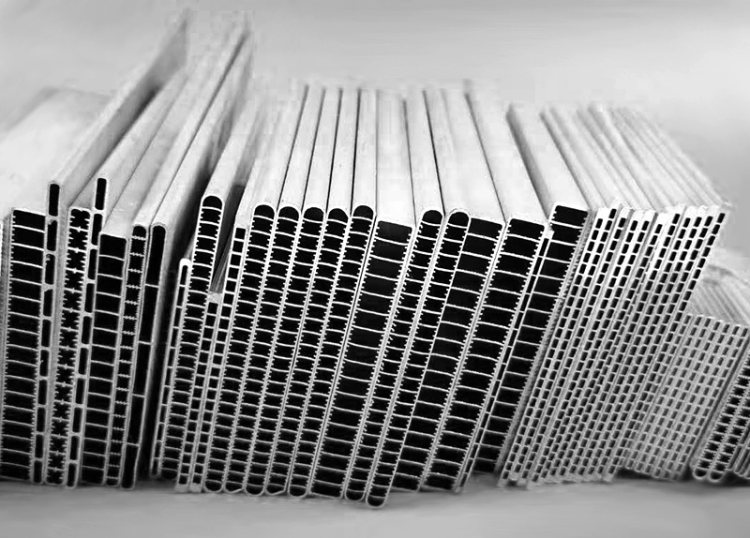

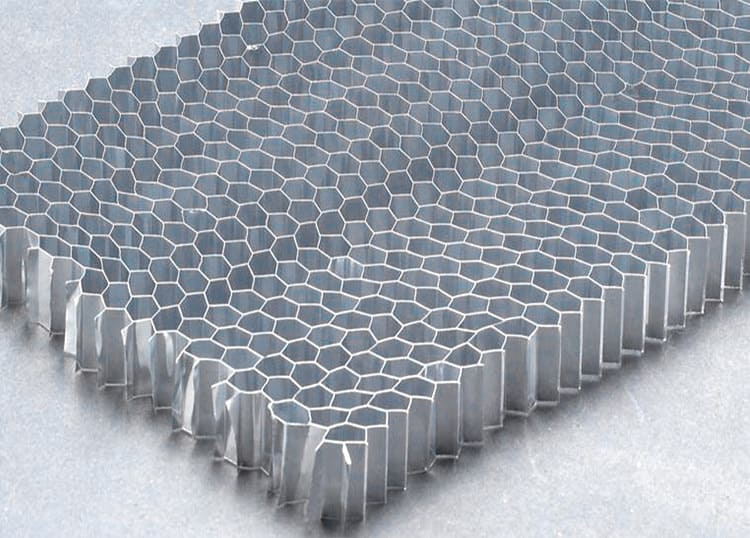

What is Aluminium Foil Made Honeycomb Core?

The Aluminium Foil Made Honeycomb Core is a regular honeycomb shape formed by bonding, laminating, stretching, and unfolding through multiple layers of aluminum foil. Due to the special structure of Aluminium Foil Made…

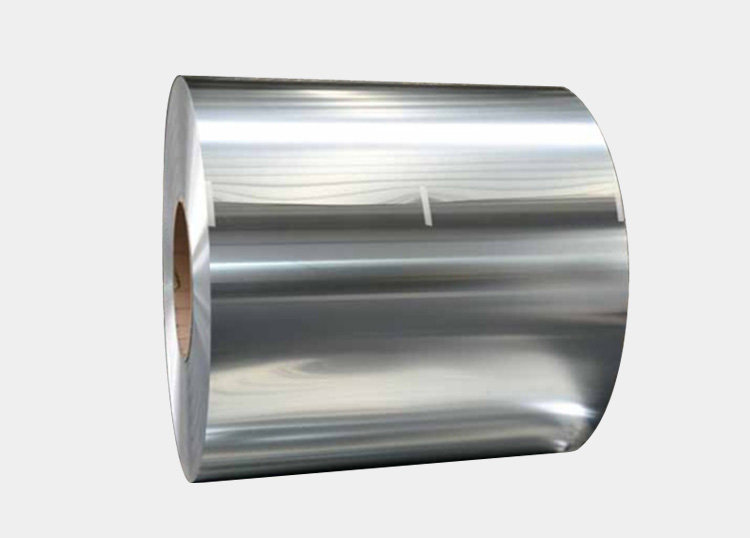

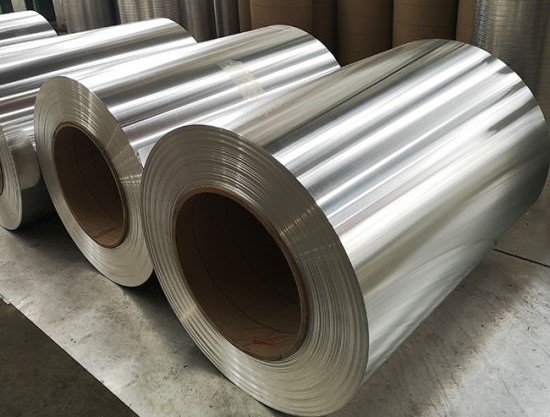

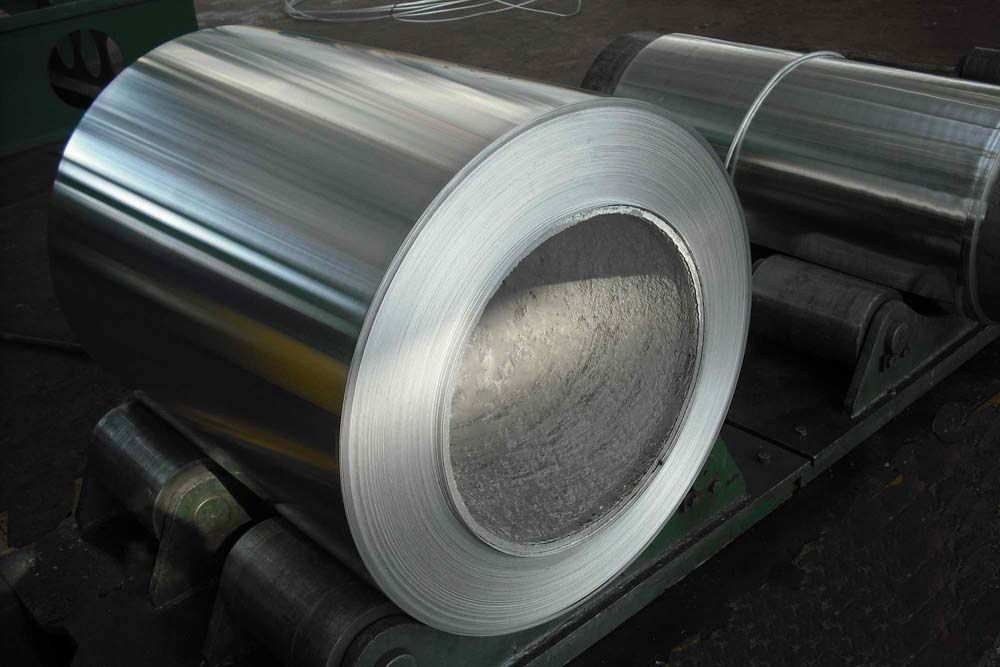

How to Choose an Aluminum Coil? Just Reading This Article!

Do you know aluminum coils? Have you heard of the 3003 aluminum coil? 1050 aluminum coil? 6061 aluminum coil? What do they mean? Why are there so many types of…

Why is the Anodized Aluminum Coil Getting More Popular?

Compared to any other metal available in the construction market, anodized aluminum coil provides weight, durability and aesthetics that can benefit construction companies and owners. Its extreme durability, lightweight, high strength-to-weight ratio and ease…

Some Odd Uses of Aluminum Coil You Barely Know

What is Aluminum Coil? An aluminum coil is a long strip of aluminum that has been rolled into dense coils. Aluminum coils can be produced more efficiently and cheaply than many other…

Difference Between Aluminium Tube and Steel Tube

Aluminium tubes and steel tubes are ubiquitous in automotive, aerospace, industrial, construction, research, and medical applications. Both of them have their advantages and disadvantages, but each material has its obvious characteristics…

To Understand Electronic Aluminum Foil, Just Read This Article

As one of the core materials of electronic devices, electronic aluminum foil has always been the focus of electrical appliance manufacturers. As a term that doesn’t appear often, you may have…

Clearest Introduction of the Strength of 5052 Aluminum Coil

Modern commercial aluminum comes in many types, called alloys, each offering unique benefits, depending on the alloy chosen. Alloys are reinforced engineering materials made by adding unique elements to base…