Aluminium tube is an extruded material composed of aluminium alloy, usually described as an architectural or structural alloy, suitable for internal and external architectural applications. They have high corrosion resistance and medium strength.

Nowadays, more and more manufacturers in the manufacturing industry choose to use aluminium tubes instead of steel tubes. What is the reason behind this trend? Generally speaking, the price of aluminium tube is slightly higher than that of steel tube. Why do manufacturers choose to replace original steel tube products at a higher price? This article will analyze the causes of this situation in detail and recommend a suitable aluminium tube supplier to help answer your questions and meet your needs.

1. Performance comparison of aluminium and steel

Steel is a kind of hard metal in the traditional concept and is used in many fields. The product names of aluminium tubes are usually non-uniform. They are usually called aluminium tubes, aluminium pipes or aluminium rods. These names all represent the same product. The performance between steel tube and aluminium tube is mainly different from the above and the following aspects:

- Weight: Aluminium is lighter. The density of aluminium is 2.72 tons/m3, while steel is 7.84 tons/m3. Reduce the load capacity, thereby increasing the cargo capacity. Many containers now have upper structures made of aluminium. This leads to a lowered center of gravity. Therefore, the stability is improved. Lower hull weight requires less propulsion, and higher speed for the same power. Many fast ferries, hovercraft and catamarans have entire hulls constructed of aluminium alloy.

- Durability: Compared with steel. Aluminium tubes are more durable than steel tubes at lower temperatures. Steel becomes brittle at low temperatures, forming rapidly spreading cracks. Aluminium does not have this disadvantage, which makes it suitable for use as a tank material on LPG and LNG carriers.

- Extensibility: Aluminium is a very ideal metal, because aluminium is more ductile and elastic than steel. Aluminium can replace steel to form shapes, often forming deeper or more complex spinning. Especially for parts with deep and straight walls, aluminium is the preferred material. Steel is a very tough and elastic metal, but usually cannot be pushed to the same limit size limit as aluminium during rotation without cracking or cracking.

- Corrosion resistance: Aluminium has good corrosion resistance and will not rust. Aluminium is non-magnetic. The absence of an induction magnetic field benefits compasses and other similar devices on ships. This quality is particularly useful in warships, which can keep them from being affected by mines.

2. In which applications can aluminium tube replace steel tube?

By volume, steel is three times heavier than aluminium. Aluminium tubes can replace steel in many significant industries for conventional and special applications, such as:

- Aerospace and automotive. Aerospace and automobile manufacturers use aluminium tubes for airframe, hydraulic system and fuel line components.

- Aluminium materials can be used in a wide range of construction applications, such as roofing, wall panels, door and window frames, and building curtain walls.

- HVAC and refrigeration. Aluminium tubes have excellent thermal conductivity and therefore play a central role in many HVAC and refrigeration systems.

- Marine Corps. Aluminium tubes are used to build marine equipment, such as shark cages, because this metal has greater buoyancy and salt water corrosion resistance than other building materials.

- Manufacturers of medical tools and equipment often use aluminium tubes to construct products such as bed frames, foldable stretchers and wheelchair frames.

- Amusement equipment manufacturers use aluminium tubes to make equipment such as camping chairs, tables, and tent poles.

Aluminium can be mixed with other metals to form a harder aluminium alloy, which can replace most of the functions of steel and has stronger corrosion resistance.

3. Why are manufacturers more willing to choose Aluminium in these fields?

Generally speaking, the average price of Aluminium is higher than that of steel, but many manufacturers are willing to choose higher-priced Aluminium tubes. One of the reasons is that Aluminium has higher economic benefits. Although the initial purchase price of Aluminium is more expensive than steel, its use efficiency and life span are both better and longer than steel.

- Compared with steel, Aluminiumis lighter in volume. Aluminiumis one-third the weight of other metals including steel, brass and copper. According to the Aluminium Association, Aluminium car structures are more cost-effective than steel car structures: the use of Aluminium can reduce weight by up to 55% compared to steel structures.

- In the maritime industry, Aluminiumstructures are more cost-effective than steel. The weight of the Aluminiumshell is reduced by 35% to 45%. If Aluminium is used instead of steel to build the ship’s superstructure, the weight can be reduced by 55% to 65%. This is a very cost-effective embodiment for ocean transportation.

- In the electronic parts industry, Aluminiumfuel and battery consumption are more cost-effective than steel structures because light vehicles consume less energy. According to the Aluminiumdrive, an electric car with an advanced Aluminium body structure uses fewer batteries than a steel body structure, so it can save up to $3,000 in weight per unit. Compared with steel hybrid vehicles, Aluminium hybrid vehicles can save 5% to 7% of fuel.

- In the field of food packaging, Aluminiumhas good ductility and can be made into any shape to meet the packaging needs of various foods. And Aluminiumis safer than plastic, more resistant to high temperatures and easy to store.

- Aluminiumis not easy to rust due to its strong corrosion resistance, and is more beautiful than other metals and has a longer service life. In addition, Aluminiumcan be recycled, which is more environmentally friendly.

Although the price of Aluminium raw materials is a bit more expensive than steel, from the perspective of long-term use, the economic efficiency of choosing Aluminium is higher than that of steel, and the service life of Aluminium is longer than that of steel and consumes less energy. Therefore, between Aluminium pipe and steel pipe, choosing Aluminium pipe has become a more correct decision.

4. Aluminium tube supplier recommendation

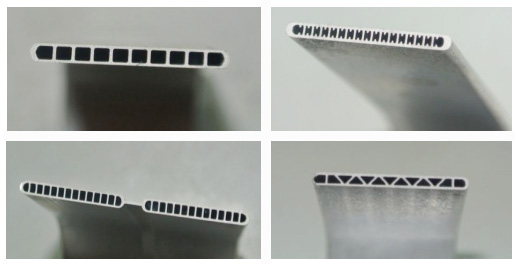

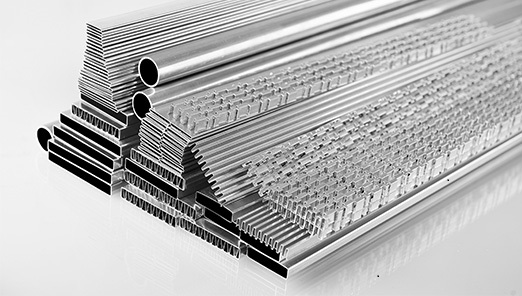

The quality of aluminium tube suppliers on the market is uneven, and the quality and price of aluminium tubes cannot be guaranteed. CHAL Aluminium Corporation is one of the leading aluminium tube suppliers in China. Its products are widely used in the automotive industry, construction industry, HAVC&R and heat transfer industry, aviation, railway transportation, marine industry, etc. Our main aluminium tubes include the following:

Aluminium High-Frequency Welded Tube

Composite Aluminium Tube (Al-Al Composite Tube)

Aluminium Condenser Header Pipe

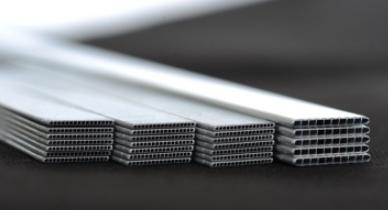

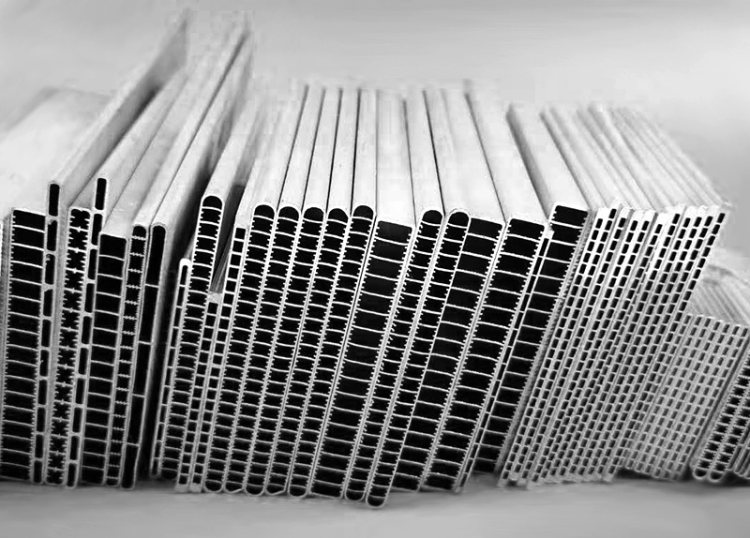

Aluminium Multi-Channel/Multi-Port Tube

If you have any needs about aluminium tubes, please feel free to contact us, we will help your manufacturer produce the best and more cost-effective products imaginable.