Header tubes are crucial components in performance exhaust systems, playing a vital role in optimizing exhaust flow and engine performance. Choosing the right material for your header tubes is essential, and two main contenders dominate the market: aluminum and stainless steel. This article delves into the key differences between these materials, highlighting the advantages of choosing aluminum header tubes for performance-oriented applications.

Material Properties: Understanding the Differences

Aluminum and stainless steel are the two most common materials used for header tubes, each possessing unique properties. Let’s explore these properties in detail:

Strength

- Yield Strength: Stainless steel offers superior yield strength, meaning it can withstand greater stress before permanently deforming. This is particularly important for highly tuned engines that generate immense power.

- Tensile Strength: While stainless steel boasts higher tensile strength at room temperature, aluminum’s strength diminishes significantly at higher temperatures. This can be a concern for extreme racing conditions or turbocharged engines.

Weight

Aluminum reigns supreme regarding weight reduction. An aluminum header tube can be up to 50% lighter than its stainless steel counterpart. This significant weight reduction translates to numerous performance benefits, including improved acceleration, handling, and fuel efficiency.

Corrosion Resistance

Stainless steel shines in terms of corrosion resistance, especially in harsh environments with high salt content. It forms a natural oxide layer that protects the underlying metal from rust and oxidation. Aluminum, while possessing decent corrosion resistance, requires regular cleaning and maintenance to prevent corrosion.

Heat Transfer

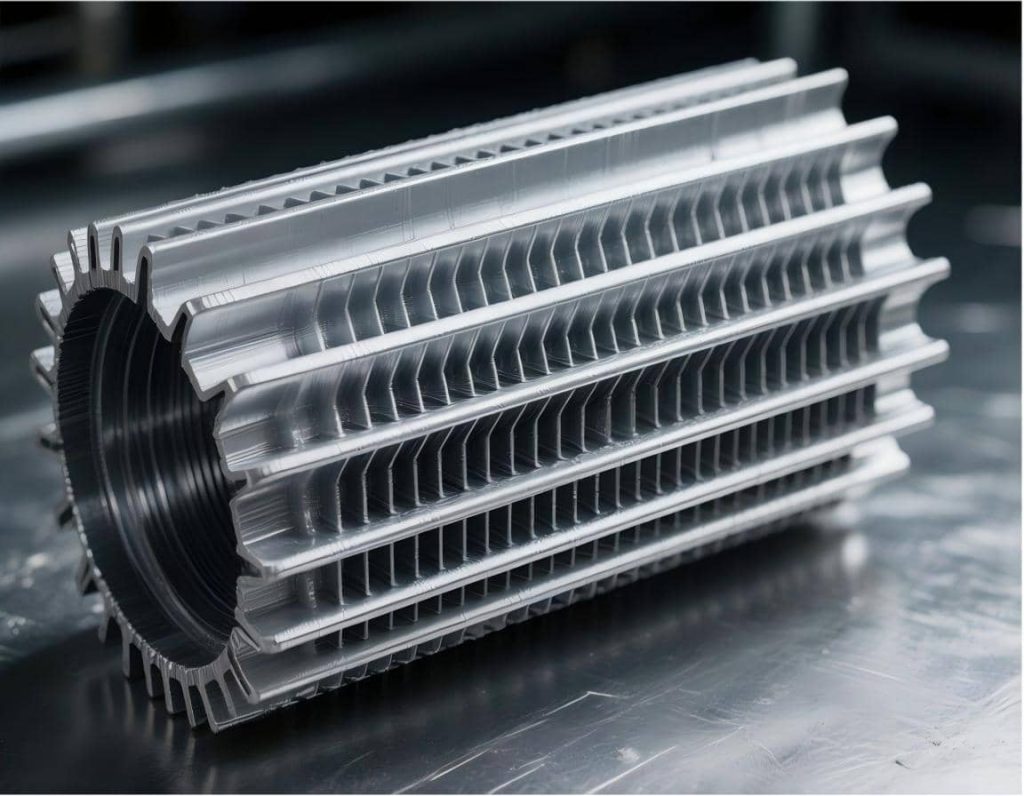

Aluminum excels in heat transfer due to its higher thermal conductivity. This allows for faster exhaust gas expulsion, leading to enhanced engine performance and lower exhaust gas temperatures. Efficient heat dissipation also helps protect other engine components from thermal stress.

Cost

Generally, aluminum header tubes are more affordable than stainless steel options. This is due to its lower material cost and ease of fabrication. However, the lower cost needs to be weighed against the potentially higher maintenance requirements and shorter lifespan of aluminum headers.

Advantages of Choosing Aluminum Header Tubes

The distinct advantages of aluminum header tubes make them a compelling choice for many applications. Here’s why you might choose aluminum over stainless steel:

Significant Weight Reduction

The reduced weight of aluminum leads to several performance benefits:

- Improved Acceleration: Lighter exhaust system allows the engine to accelerate faster with less resistance.

- Enhanced Handling: Reduced weight distribution leads to improved responsiveness and agility, especially when cornering.

- Lower Fuel Consumption: Less weight translates to less energy needed to move the vehicle, resulting in improved fuel efficiency.

Improved Exhaust Flow

Aluminum’s superior thermal conductivity promotes quicker exhaust gas expulsion, leading to:

- Increased Engine Performance: Faster removal of hot exhaust gases allows the engine to breathe more efficiently, leading to a potential increase in horsepower and torque.

- Lower Exhaust Gas Temperatures: Quicker exhaust flow reduces the heat buildup in the engine bay, protecting other components and improving engine longevity.

Cost-Effectiveness

Aluminum header tubes are generally more affordable than stainless steel options, making them a budget-friendly choice. This is especially relevant for enthusiasts who want to maximize performance without breaking the bank.

Considerations When Choosing Aluminum Header Tubes

While aluminum offers several advantages, some crucial considerations need to be addressed:

Lower Maximum Operating Temperature

While aluminum can withstand high temperatures, it has a lower maximum operating temperature compared to stainless steel. This may limit its suitability for highly tuned engines or extreme racing conditions requiring consistent high-temperature operation. Proper heat management strategies like heat shields or ceramic coatings are crucial when using aluminum headers in such situations.

Potentially Lower Durability

Aluminum is generally less durable than stainless steel. It is more susceptible to physical damage, such as dents or cracks, requiring careful handling and installation. Additionally, the lifespan of aluminum headers can be shorter than stainless steel, especially under harsh conditions.

Corrosion Concerns

Although aluminum possesses decent corrosion resistance, it is still susceptible to oxidation and rust in harsh environments. Regular cleaning and maintenance are crucial to prevent corrosion and extend the life of aluminum headers.

Conclusion

Choosing the right material for your header tubes depends on your specific needs and priorities. If your primary focus is on maximizing performance and fuel efficiency within budget constraints, aluminum header tubes offer a compelling choice. Their significant weight reduction and improved exhaust flow translate to noticeable performance gains, making them ideal for performance enthusiasts. However, for applications demanding exceptional durability and corrosion resistance in harsh environments, stainless steel remains the preferred option, despite its heavier weight and higher cost.

Ultimately, choosing between aluminum and stainless steel comes down to balancing performance, budget, and intended use. Weigh the advantages and drawbacks carefully to select the material that best aligns with your specific requirements and objectives.