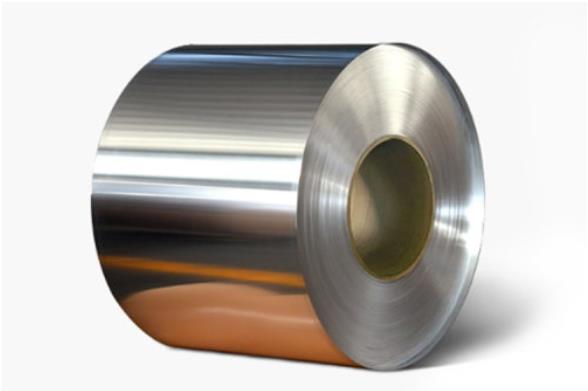

Compared to any other metal available in the construction market, anodized aluminum coil provides weight, durability and aesthetics that can benefit construction companies and owners. Its extreme durability, lightweight, high strength-to-weight ratio and ease of installation make it a powerful material, while its natural 3D metallic appearance and color choice ensure superior aesthetics. Anodized aluminum can provide similarities to many different metals for building applications, but is easier to install, less costly, and better weather-resistant.

Stronger than other metals in strength

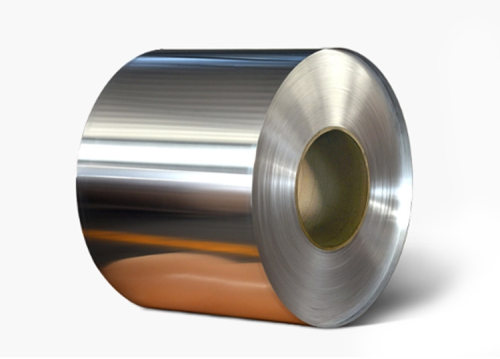

Continuous coil anodizing provides superior quality in terms of strength and durability of the final product, contributing to the overall durability of the exterior of the building. The continuous coil is anodized to form a transparent protective oxide layer with a hardness similar to sapphire — second only to sapphire (diamond is the hardest) — that protects the metal from corrosion and wear over time. If damaged, it will also repair itself, as aluminum naturally forms a protective oxide layer wherever it is exposed to the element.

More durable than other metals

The three-dimensional crystal structure of the aluminum layer also reflects and refracts light in ways that help activate the surface. Unlike paints or coatings, this oxide is grown from primary aluminum and binds at the molecular level, so it does not chip, flake or peels off as paints and coatings often do.

Unlike other coloring processes, including batch anodizing, continuous coil anodizing can meet the need for excellent color consistency, even in multiple coil or production runs. This unparalleled level of consistency exists somehow because the continuous coil anodizing process exposes every square inch of the coil to each part of the process for the same amount of time.

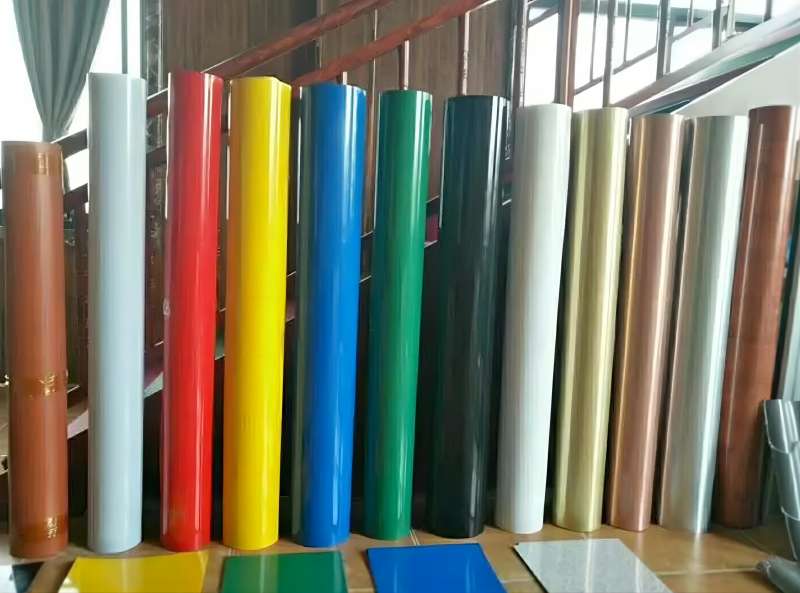

More Styles than other metals

Anodic aluminum can be made into almost any other metal, including brass, copper, bronze, zinc, gold, silver, stainless steel, titanium and carbon steel, through additives in the coil anodizing process. However, anodized aluminum does not tarnish like brass, does not tarnish like copper, and does not fade like bronze, so the appearance of these metals remains stable over time and with UV exposure.

Ease Of Installation And Competitive Costs

Natural metals are a commodity, so prices can fluctuate to some extent. However, anodic aluminum is two-thirds lighter than other metals and has a high strength-to-weight ratio, typically costing 60 to 70 percent less per square foot than many other natural metals. This also helps save costs on the structural side of the project, as the structure does not need to support the significantly increased weight as copper or steel does.

anodized aluminum coil is simple to process and install because the material is light and easy to process. This solves many of the challenges faced in construction due to rigid or heavy materials. Many anodized aluminum panels can be installed on buildings using standard hand tools without the cost of a crane as with other materials.

an anodized aluminum coil can also be perforated to a range of opening percentages in various patterns before anodizing. Perforated aluminum, when used on the exterior walls of buildings or garages, provides noise control, improves HVAC efficiency, shields from sunlight and environmental particulates, and manages the wind or heat load of the structure — all with lower weight requirements.

| Beneficial ways | Details |

| features | Resist from corrosion and abrasion over the long term. Compared with other metals, aluminum can do self-healing if damaged. |

| Cost | cost savings for structural aspects of the project, as the structure does not need to support significant added weight as in the case of copper or steel |

| Operation | The handling and installation of coil-anodized aluminum are simple |

Conclusion

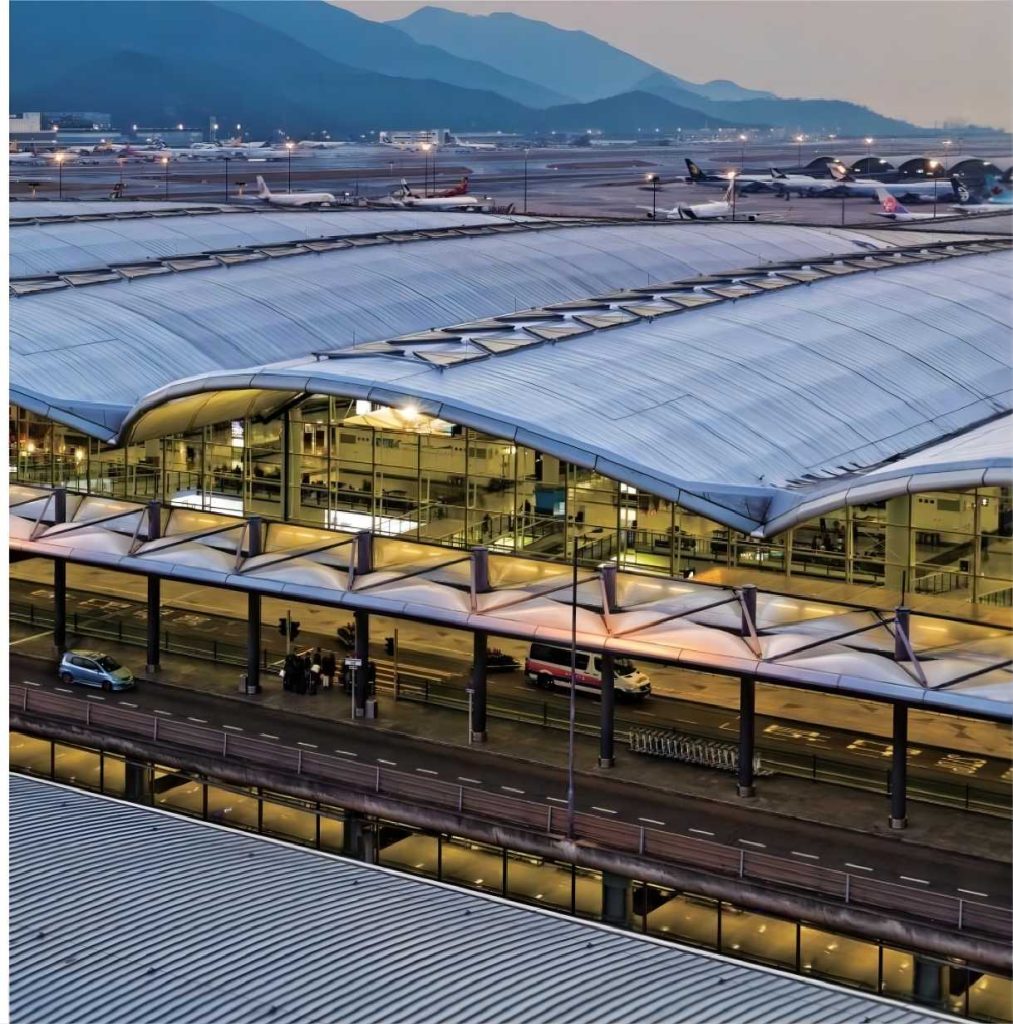

an anodized aluminum coil can be used in a wide range of building and construction applications, including building facades, curtain walls, roofing, column wrapping and lighting. Building facades can be installed as honeycomb panels, aluminum composite panels, solid metal panels and rolled molded panels. In all these applications, it offers a wide range of benefits to construction companies installing aluminum products and to building owners concerned with cost, durability and aesthetics.

With the functional advantages of high strength-to-weight ratio and superior durability, as well as the aesthetic advantages of natural metal appearance in a variety of colors, anodized aluminum is particularly suited to bring significant benefits to owners and construction companies.