Aluminum Foil Lunch Box: the Best Choice for Airline

The airline’s meals are prepared by in-flight catering companies at various airports, and delivered to the aircraft cabin on time according to flight needs. For a flight of more than…

Clear Comparison Between Aluminium Circle And Steel for Wheel

When it comes to aluminium circle wheels, I believe that the most intuitive impression of many people is lightness and beauty. In fact, in addition to being light, the advantage of…

4 Secrets of Aluminium Coil

Thermal insulation aluminum coil is a new type of high-grade exterior material integrating energy-saving decoration. It has been widely used in the construction field, and its functional advantages have been trusted…

What is the Aluminium Alloy Production Process?

An aluminum plate or aluminum strip made of aluminum is the main raw material mixed with other alloying elements. Aluminum strip is an essential basic material for developing my country’s…

Some Clever Using Ways of Aluminum Foil Tape You Should Know

Aluminum foil tape is mainly based on aluminum foil, coated with acrylic adhesive, with high peel strength, excellent adhesion, oxidation resistance, corrosion resistance, and flame resistance. Since it is made…

Small Size of Aluminum Foil Lunch Box Gives Huge Contribution To Covid-19

The aluminum lunch box is the very key to COVID-19. It can avoid many serious infections of viruses. Since the start of COVID-19, people have begun to go against the…

Useful Tips to Heat Food in Aluminium Foil Container

How do you reheat food in aluminum foil containers? You might ask when you eat your food, and you might realize that you might have leftovers. In this case, it’s…

Did You Know Aluminum Foil Food Containers Can Be Recycled!

In a lot of publicity about garbage sorting, used lunch boxes are classified as “other garbage,” which is okay for lunch boxes of other materials! However, the used Aluminium Foil Container can…

What are the effects of heat treatment on 2024 aluminum alloy?

Aluminum alloy is the largest amount of non-ferrous metals, the highest output of materials is the pillar industry of the national economy, widely used in aviation, transportation, building materials, machinery,…

In China, aluminum foil food containers save “white pollution”?

In today’s prevalence of online ordering, in the face of a large amount of domestic garbage we generate every day, it is not difficult to find that plastic fast foil…

The Explosive Growth of New Energy Makes Battery Aluminum Foils Precious

The demand for aluminum foil in new energy vehicles is increasing, which is inseparable from the excellent quality of the aluminum foil. Today we will take a look at the…

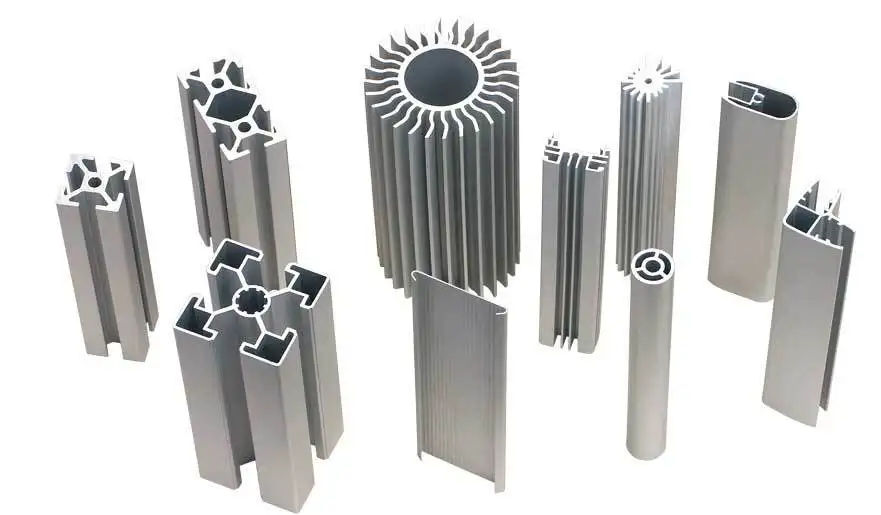

The Most Detailed Knowledge of Aluminum Profiles

Aluminum profiles are aluminum materials with different cross-sectional shapes through hot melting and extrusion of aluminum rods. The production process of aluminum profiles mainly includes three processes: casting, extrusion, and…