Have you ever thought of turning your designs into real metal components with amazing accuracy? Welcome to the thrilling world of aluminum additive manufacturing! This cutting-edge technology is often known as 3D metal printing, has been changing the way we design all kinds of aerospace parts to customized jewelry. The core of this technology is the most basic but crucial component: aluminum powder. However, not any type of aluminum is suitable. The real magic is when we speak of aluminum alloys for additive manufacturing. They are specifically designed powders that unleash the maximum potential of this transformational process. Learn more about the alloys they are made of and how they’re shaping how manufacturing will evolve in the near future!lidification and cold cracking due to hydrogen embrittlement – is fundamental. By adhering to best practices in material preparation, filler metal selection, welding parameters, and joint design, welders can significantly mitigate the risk of cracking and master the art of producing strong, durable, and aesthetically pleasing aluminum TIG welds, unlocking the full potential of this versatile material across a wide spectrum of applications.

Why Not Any Aluminum? Engineered Powders’ Necessity

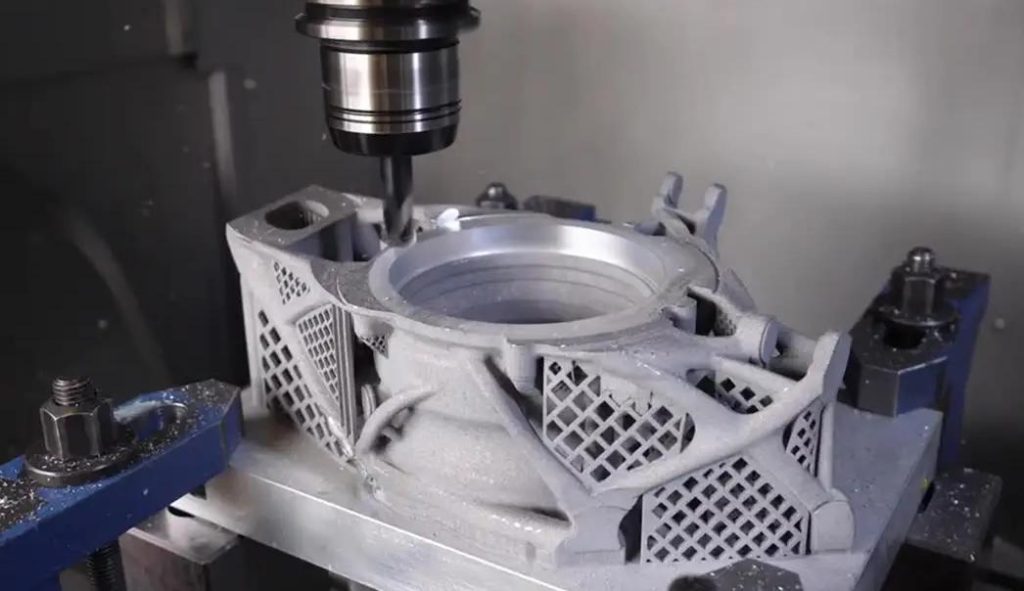

The soil in any pile will not hold its shape if one tried to create a sandcastle of it. In the same way, standard aluminum is inadequate for the complicated and precise procedures of additive manufacturing. It doesn’t matter if you are directing a stream of energy and material (Directed Energy Deposition) or melting the powder using the help of a laser (Powder Bed Fusion) The AM techniques require fast cycles of cooling and heating. In the event that aluminum particles aren’t well developed, these extreme conditions could cause major problems.

Ever thought about making your ideas into actual metal parts that are manufactured with astonishing precision? Welcome to the exciting world of additive manufacturing in aluminum! This cutting-edge technology, commonly called 3D metal printing. It has revolutionized the ways we design all sorts of aerospace components to custom jewelry. The basis of this technology is its most fundamental, but essential ingredient the aluminum powder. But, not every type of aluminum is ideal. The real magic comes when we talk about aluminum alloys that are used for additive manufacturing. They’re specifically designed to be powders that can unleash the full potential of this transformative process. Find out more about the metals they’re made of and the way they’re creating the future of manufacturing soon!

Key Aluminum Alloys Used in Additive Manufacturing

Aluminum additive alloys has an array of different alloys, each suited to specific needs and requirements for performance. For simplicity we can categorize commonly used Aluminum additive-based manufacturing alloys by their main alloying elements as well as common applications:

Common Additive Manufacturing Aluminum Alloys:

| Property Category | Key Alloying Elements (Main) | Typical Composition (Approximate Range, wt%) | Common Examples | Main Characteristics | Typical Applications |

| High Strength | Aluminum (Al), Magnesium (Mg), Scandium (Sc), Copper (Cu) | Al-5-12Mg, Al-0.1-0.6Sc, Al-3-5Cu | Scalmalloy®, AlCu4MnSi | High tensile and yield strength, good fatigue resistance (Scalmalloy®), high hardness (AlCu4MnSi) | Aerospace structural components, high-performance automotive, tooling, motorsport |

| Good Weldability & General Purpose | Aluminum (Al), Silicon (Si), Magnesium (Mg) | Al-9-11Si, Al-0.2-0.4Mg; Al-6-8Si, Al-0.2-0.6Mg | AlSi10Mg, AlSi7Mg | Good printability, moderate strength and ductility, good corrosion resistance (Al-Si-Mg) | General engineering parts, automotive components, heat sinks, brackets, housings |

| High Ductility & Corrosion Resistance | Aluminum (Al), Magnesium (Mg) | Al-4-6Mg | AlMg5 | High elongation, good corrosion resistance, moderate strength | Marine applications, food processing equipment, components requiring good formability |

Note: The “Typical Composition” provides a general range for the main alloying elements. Other minor elements may also be present to influence specific properties.

Properties and Performance of AM Aluminum Alloys

The unique process conditions of aluminum additive manufacturing may produce microstructures and other properties that are different from traditional components. But, with the correct alloy and printing parameters that are optimized high performance can be obtained.

Here are the properties of two typical types:

| Property | Typical Values for AM AlSi10Mg (Heat Treated) | Typical Values for AM Scalmalloy® (Heat Treated) | Notes |

| Tensile Strength | 400-450 MPa | > 500 MPa | Indicates the maximum stress the material can withstand before breaking. |

| Yield Strength | 300-350 MPa | > 450 MPa | Indicates the stress at which the material begins to deform permanently. |

| Elongation at Break | 5-10% | 10-15% | Measures the ductility or how much the material can stretch before breaking. |

| Hardness (HV) | 120-130 | 140-160 | Resistance to indentation. |

The tailored properties of these aluminum additive manufacturing alloys are what make them so valuable for creating functional and high-performance parts through 3D printing.

What Makes Our Aluminum Powders Different?

At Chaluminium, we pride ourselves on producing high-quality aluminum powders designed for AM. Here’s what sets us apart:

| Features | Descriptions |

| Quality Control | Each batch undergoes rigorous testing to ensure consistency and reliability. |

| Particle Size Distribution | Ensures uniform melting and reduced defects. |

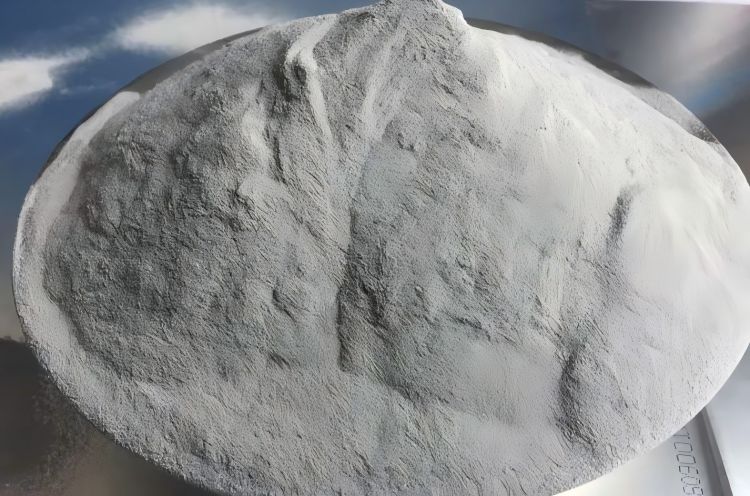

| Morphology (Shape) | Spherical particles enhance flowability in AM. |

| Purity and Composition | High purity minimizes impurities and enhances strength. |

By focusing on these critical aspects, we provide aluminum additive manufacturing powders that empower you to achieve exceptional results in your 3D printing endeavors.

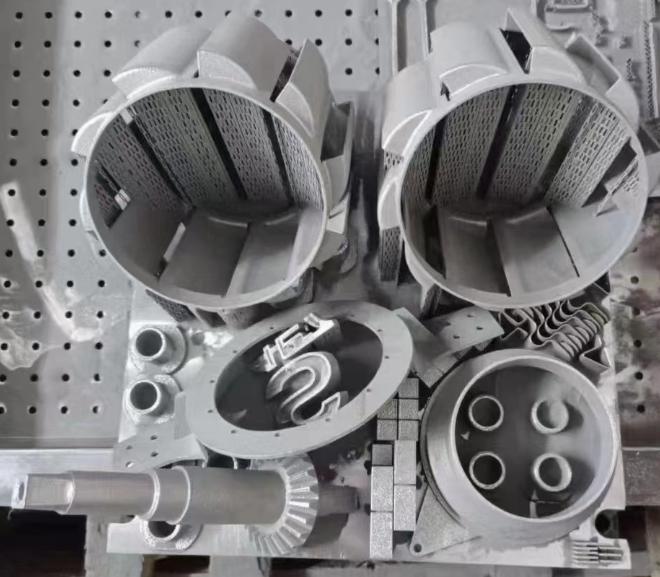

Applications and Benifits of Aluminum AM

The wide applications show the versatility of Aluminum AM, utilizing aluminum additive manufacturing parts made from quality powder translates to tangible advantages for end users:

| Industry | Component Application Examples | Benefits of AM |

| Aerospace | Cabin brackets, ducting, fuel nozzles, turbine blades, satellite components, tooling (jigs, molds). | Weight reduction for fuel efficiency, complex geometries for optimized performance, rapid prototyping, on-demand manufacturing of spare parts. |

| Automotive | Lightweight structural components, customized interior parts, prototyping of engine parts, tooling (molds, fixtures), spare parts on demand. | Weight reduction for better fuel efficiency, design flexibility for performance enhancement, rapid prototyping, customization. |

| Consumer Goods | Customized eyewear, personalized sporting equipment (bike saddles, golf clubs), jewelry, individualized prosthetics, rapid prototyping of new designs. | Mass customization, complex and intricate designs, rapid product development, lightweighting, personalized fit and function. |

| Medical | Patient-specific implants (orthopedic, dental), surgical guides, anatomical models for planning, prosthetics, orthotics, customized instruments. | Tailored fit and function, complex geometries for biocompatibility and osseointegration, improved surgical precision, rapid creation of models. |

| Tooling | Injection molds with conformal cooling channels, customized fixtures and jigs, casting patterns, rapid prototyping of tools. | Reduced lead times, cost-effective for low volumes, design optimization for efficiency (e.g., cooling), customized solutions for specific needs. |

Choosing the Right Aluminum Powder for Your AM Project

The choice of the right manufacturing powder for aluminum additives is an essential choice that will directly impact the outcome of your project. A variety of factors must be assessed to ensure that you obtain the results you want.

| Factor | Description | Questions to Consider |

| Required Mechanical Properties | The strength, ductility, hardness, and other mechanical characteristics needed for the final part’s function. | What are the load-bearing requirements? Does the part need to be flexible or rigid? What is the expected service life and operating environment? |

| Application Requirements | The specific demands of the intended use, such as corrosion resistance, thermal conductivity, or biocompatibility. | Will the part be exposed to harsh environments? Does it need to dissipate heat efficiently? Is it for medical use? |

| AM Process Compatibility | Different AM processes (e.g., Powder Bed Fusion, Directed Energy Deposition) have varying requirements for powder characteristics. | Which 3D printer will be used? What are the recommended powder specifications for that machine? |

| Post-Processing Considerations | The need for subsequent treatments like heat treatment, surface finishing, or machining can influence alloy selection. | Will the part require heat treatment to achieve desired properties? Does it need a specific surface finish? |

| Cost and Availability | The price and accessibility of different aluminum alloy powders can vary significantly. | What is the budget for the project? How readily available is the desired powder? |

By carefully assessing these elements and analyzing the properties of various alloys for additive manufacturing and alloys, you will be able to make an informed choice that is in line with your specific project’s requirements and limitations. Do not hesitate to speak with experts in the field of materials and powder providers similar to ours to make sure you pick the appropriate aluminum powder for the best outcomes for your additive manufacturing projects. If you require additional additive manufacturing materials, like bronze powder Please reach us via email.