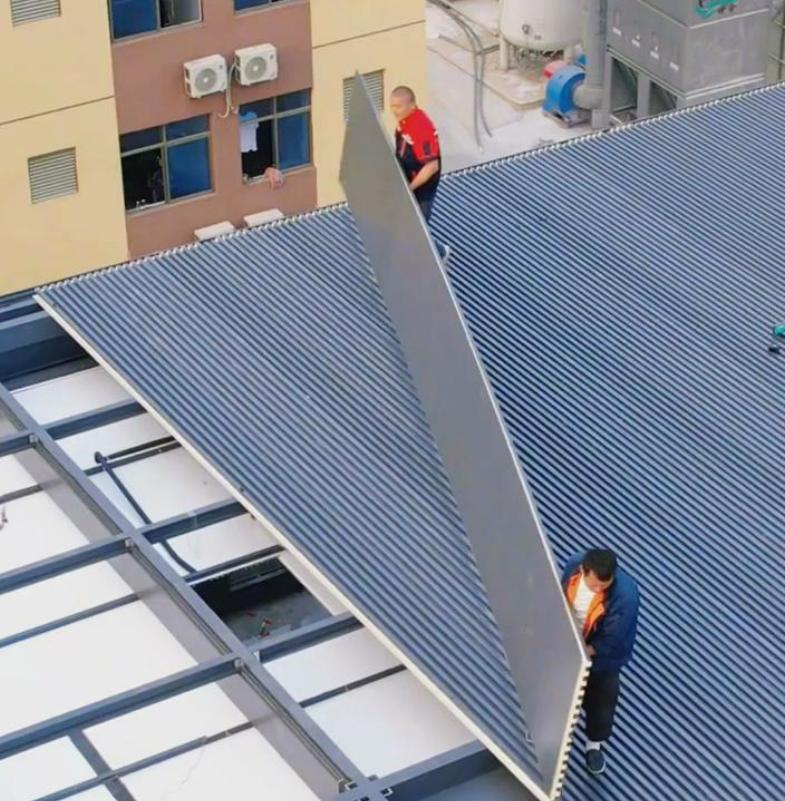

Aluminum roofs are highly valued for their durability, lightweight structure, and corrosion resistance. However, as summer temperatures rise, so often do our energy bills. Homeowners and building managers constantly seek effective ways to maintain comfortable indoor environments without incurring exorbitant cooling costs. One often-overlooked yet highly effective solution lies right above our heads: the roof. Specifically, applying a high-quality aluminum roof coating can significantly impact your building’s energy efficiency.

This article explores the science, benefits, and types of aluminum roof coatings, helping you make informed decisions about protecting your investment.

The Science Behind Cooling: Reflectivity and Emissivity

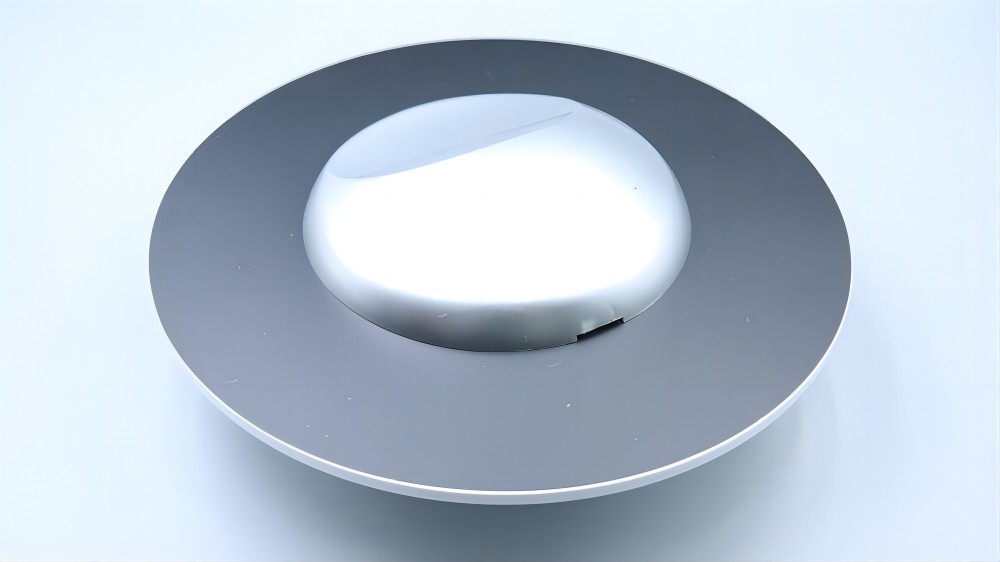

To understand how aluminum roof coatings keep buildings cool, it’s essential to grasp two key scientific principles: solar reflectance and thermal emissivity. These properties dictate how a surface interacts with the sun’s energy.

- Solar reflectance, also known as albedo, is a measure of how much solar energy (including visible light, infrared, and ultraviolet wavelengths) a surface reflects away. A highly reflective surface sends sunlight back into the atmosphere rather than absorbing it. For instance, a black asphalt roof might reflect only 5-10% of solar energy, absorbing the rest as heat. In contrast, a high-quality aluminum roof coating can reflect 70-85% or even more. This direct reflection is the primary mechanism for preventing heat buildup in the roof structure.

- Thermal emissivity, on the other hand, refers to a material’s ability to release absorbed heat. Even highly reflective surfaces will absorb some solar energy. High emissivity means that whatever heat is absorbed can be quickly re-radiated back into the atmosphere, rather than transferring it down into the building’s interior. A material with high emissivity will cool down faster once the sun sets or is no longer directly hitting it. For example, a polished metal surface might have low emissivity, trapping heat, while a properly formulated aluminum roof coating is designed to have both high reflectance and high emissivity, ensuring minimal heat transfer into your building.

These two properties are crucial in preventing your roof from becoming a heat sink. By maximizing solar reflection and enhancing thermal emissivity, aluminum roof coatings actively prevent heat from entering your building, directly leading to cooler indoor temperatures. This leads us to a crucial question: Why invest in painting your aluminum roof, especially when aluminum itself is reflective?

Why Paint Your Aluminum Roof?

While new, unpainted aluminum panels possess inherent reflectivity, their surfaces can dull, oxidize, and accumulate dirt over time, significantly reducing their reflective properties. Oxidation forms a white, chalky film that absorbs more heat, and grime further darkens the surface. Applying the best paint for aluminum roof – specifically, an aluminum protective coating – restores and enhances these critical properties. These specialized coatings are formulated with reflective pigments and binders that provide superior UV resistance and durability compared to standard paints. They create a consistent, highly reflective surface that effectively repels solar radiation, ensuring long-term energy savings and protection for the underlying aluminum.

How Aluminum Roof Coatings Lead to Energy Savings

The direct link between a coated roof and reduced cooling costs is straightforward: less heat absorbed by your roof means less heat entering your building, which in turn means less work for your air conditioning system.

Consider a hot summer day. An uncoated, dark-colored roof can reach surface temperatures of 150-180°F (65-82°C) or even higher. This extreme heat radiates downward, directly warming your attic space and the rooms below. Your air conditioner then has to work overtime, consuming significant electricity to counteract this heat gain.

By contrast, a roof treated with a high-performance aluminum roof coating might only reach 90-100°F (32-38°C) on the same day. This dramatic difference of 60-80°F (33-44°C) on the roof surface translates directly into cooler interior temperatures. Studies have shown that cool roofs can reduce peak cooling demand by 10-15%. For a typical commercial building, this can result in substantial energy savings. For example, a study by the Lawrence Berkeley National Laboratory estimated that widespread adoption of cool roofs could save California alone billions of dollars in energy costs over several decades. For a homeowner, this often means a noticeable 15-25% reduction in their monthly cooling bills.

| Roof Surface Temperature (Typical Summer Day) | Energy Impact (Approximate) |

| Uncoated Dark Roof (150-180°F) | High energy consumption |

| Coated Aluminum Roof (90-100°F) | Significant energy savings |

Beyond the immediate energy savings, the reduced strain on your HVAC system means it cycles less frequently and operates under less stress. This can extend the lifespan of your air conditioning unit, deferring costly repairs or premature replacement, and adding another layer of financial benefit to your investment in an aluminum protective coating.

Types of Aluminum Roof Coatings and Their Advantages

The market offers various aluminum roof coatings, each with specific characteristics designed for different needs and applications. Understanding these differences helps in selecting the most effective solution for your roof.

Types and Advantages

| Coating Type | Description & Key Advantages | Ideal Use Case |

| Standard Aluminum Roof Coating | An asphalt or acrylic base with aluminum pigments. Offers excellent solar reflectance, significantly lowering roof temperatures and energy costs. Provides UV protection and basic waterproofing. | General use on flat/low-slope roofs (modified bitumen, built-up, some metal) where primary concerns are reflectivity and basic weather defense. Budget-friendly. |

| Fibered Aluminum Roof Coating | Includes reinforcing fibers for added strength. Offers enhanced durability, crack resistance, and superior waterproofing by bridging small imperfections. Often lasts longer than standard coatings. | Recommended for roofs with minor surface flaws, small cracks, or in areas with significant temperature swings. Good for flat roofs needing extra structural integrity. |

| High-Performance Aluminum Protective Coatings | Advanced acrylic or elastomeric formulations. Provides exceptional, long-lasting reflectivity and emissivity, superior flexibility, and strong adhesion. Resistant to ponding water and harsh chemicals. Often considered the best paint for aluminum roof for demanding applications. | Best for commercial/industrial buildings or high-value residential properties where maximum performance, longevity, and certified energy savings are critical. Ideal for top-tier protection against severe weather. |

Beyond Cooling Costs: Additional Benefits

While energy savings are a primary driver, aluminum roof coatings offer a multitude of other advantages:

- Extended Roof Lifespan: By forming a seamless, protective barrier, these coatings shield the underlying roofing material from the damaging effects of UV radiation, oxidation, acid rain, and extreme weather. This significantly slows down the aging process of the roof, delaying the need for costly full roof replacement by many years. A well-maintained coated roof can last 5-10 years longer than an uncoated one.

- Superior Waterproofing and Leak Prevention: Coatings fill and seal tiny cracks, pores, and seams on the roof surface, preventing water penetration. This creates a monolithic, waterproof membrane that effectively stops leaks, protecting the building’s interior and structural components from water damage.

- Enhanced Aesthetics: An old, weathered roof can be an eyesore. Applying an aluminum roof coating gives it a fresh, uniform, and attractive appearance, boosting curb appeal and potentially property value.

- Reduced Urban Heat Island Effect: On a broader environmental scale, widespread adoption of cool roofs, including those with aluminum roof coatings, can help mitigate the “urban heat island effect.” This phenomenon sees urban areas becoming significantly warmer than surrounding rural areas due to heat absorbed by dark surfaces. By reflecting solar radiation, cool roofs help lower ambient air temperatures in cities.

Choosing the Right Coating for Your Aluminum Roof

Selecting the appropriate aluminum roof coating involves considering several factors to ensure optimal performance and value.

Factors to Consider

- Roof Type and Condition: Assess the current state of your roof. Is it flat, low-slope, or pitched? Does it have existing damage, ponding water issues, or significant oxidation? For severely degraded roofs or those prone to cracking, a fibered aluminum roof coating might be a more suitable choice due to its enhanced durability and crack-bridging capabilities.

- Climate: In hot, sunny climates, maximizing solar reflectance is paramount for cooling benefits. In areas with significant rainfall, superior waterproofing and mildew resistance become more critical.

- Budget: While all coatings offer benefits, there’s a range in price points. Higher-performance coatings often come with a higher initial cost but can offer greater longevity and superior energy savings over time. Consider the long-term return on investment (ROI).

- Desired Lifespan and Warranty: Coatings vary in their expected lifespan and manufacturer warranties. Match the product’s expected life with your long-term plans for the building. High-quality aluminum protective coating options may offer 10-15 year warranties.

- Application Method: Some coatings are more suitable for DIY application, while others may require professional equipment and expertise. Always follow the manufacturer’s specific application guidelines.

Partner with Professional Suppliers

While the application of some aluminum roof coatings can be a DIY project, for larger commercial properties or if you’re unsure about the best product for your specific needs, partnering with experienced and reputable coated aluminium suppliers or specialized coating manufacturers is highly recommended. These professionals can provide expert advice on product selection, ensuring you get the best paint for aluminum roof tailored to your building’s requirements. They can also offer professional application services, ensuring proper surface preparation, even coating distribution, and adherence to warranty requirements. A properly applied coating performs better and lasts longer, maximizing your energy savings and protecting your investment.

Final Thoughts

The quest for energy efficiency and reduced utility bills is a constant for property owners. Investing in a high-quality aluminum roof coating offers a remarkably effective and cost-efficient solution. By harnessing the power of solar reflectance and thermal emissivity, these coatings actively prevent heat buildup in your building, significantly reducing the load on your air conditioning system and translating directly into substantial savings on your cooling costs. Please considering the power of aluminum roof coatings for your building, then you can take control of your energy bills and ensure a cooler, more comfortable environment