Welding, a fundamental process in fabrication and manufacturing, plays a crucial role in joining metallic components with precision and strength. Among the various welding techniques available, Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW), stands out for its ability to produce high-quality, clean welds, particularly when working with challenging materials like aluminum alloys. This article delves into the intricacies of aluminum TIG welding, exploring the process, the weldability of different aluminum alloys, and the common causes of cracking, ultimately providing insights into best practices for achieving flawless welds.

What is TIG Welding?

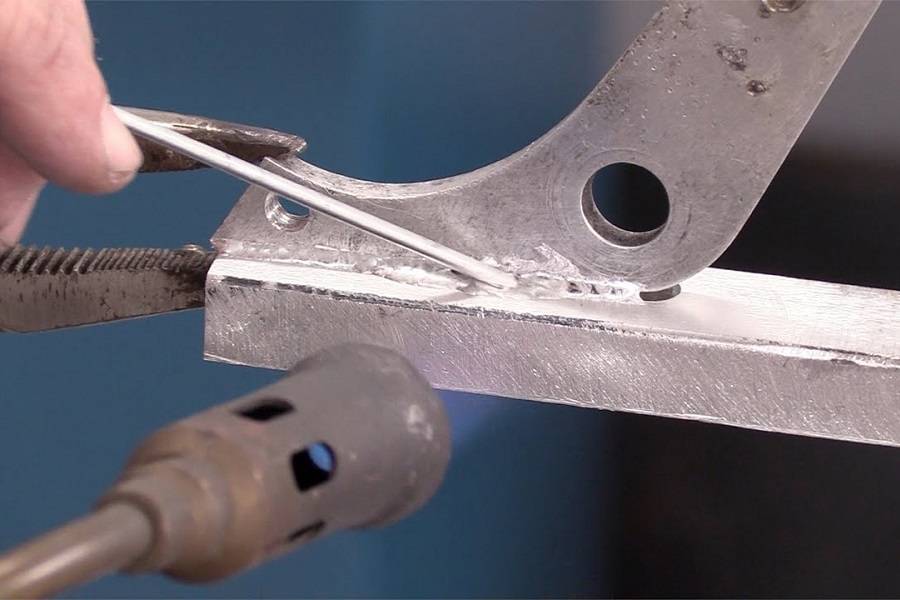

At its core, TIG welding is an arc welding process that utilizes a non-consumable tungsten electrode to generate the welding arc. This arc is established between the tungsten electrode and the aluminum workpiece, melting the base material and any filler metal introduced into the weld pool. A shielding gas, typically an inert gas like argon or helium (or a mixture thereof), is fed through the welding torch to protect the electrode, the molten weld pool, and the surrounding base metal from atmospheric contamination. Unlike other welding processes, TIG welding offers exceptional control over the heat input and the amount of filler metal added, allowing for precise and aesthetically pleasing welds. While versatile and applicable to a wide array of metals, TIG welding is particularly favored for materials like aluminum, where cleanliness and controlled heat are paramount.

What Types of Aluminum Alloys Can be TIG Welded?

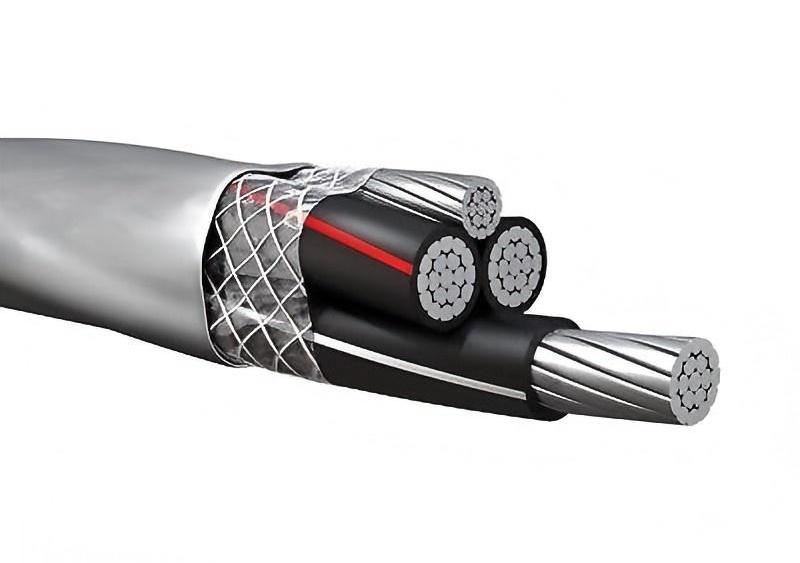

Aluminum, prized for its lightweight, corrosion resistance, and excellent conductivity, is a ubiquitous material across numerous industries, from aerospace and automotive to construction and consumer goods. However, the weldability of aluminum varies significantly depending on its alloy composition. Understanding the different aluminum alloy series and their characteristics is crucial for successful TIG welding.

Several aluminum alloy series exhibit good weldability with the TIG process:

- 1xxx Series (Pure Aluminum): These alloys, with a minimum of 99% aluminum, generally offer excellent weldability. They are typically used in applications requiring high electrical and thermal conductivity or corrosion resistance.

- 3xxx Series (Aluminum-Manganese): The addition of manganese enhances the strength of these alloys without significantly impairing their weldability. They find applications in cookware, pressure vessels, and heat exchangers.

- 5xxx Series (Aluminum-Magnesium): These alloys possess good weldability and higher strength compared to the 1xxx and 3xxx series. They are commonly used in marine applications, vehicle bodies, and storage tanks.

- 6xxx Series (Aluminum-Magnesium-Silicon): These heat-treatable alloys offer a good balance of strength and weldability. They are widely used in extrusions for architectural applications, bicycle frames, and automotive components. Post-weld heat treatment can often restore the strength lost during the welding process.

Conversely, some aluminum alloy series, notably the 2xxx (Aluminum-Copper) and 7xxx (Aluminum-Zinc) series, are generally considered less weldable due to their susceptibility to hot cracking and other welding defects. These alloys often require specialized welding techniques and filler materials to achieve acceptable results.

The selection of the appropriate filler alloy is paramount in aluminum TIG welding. The filler metal must be chemically compatible with the base material to ensure adequate weld strength and corrosion resistance and minimize the risk of cracking. For instance, when welding 5xxx series aluminum, a 5xxx series filler alloy is typically recommended. Consulting welding charts and material specifications is essential for choosing the correct filler metal for a specific aluminum alloy combination.

What Caused the Aluminum TIG Welding Crack?

Despite the precision and control offered by TIG welding, cracking remains a significant concern when welding aluminum. Understanding the primary causes of these cracks is crucial for implementing effective preventative measures. The two main types of cracks encountered in aluminum TIG welding are hot cracking and cold cracking.

1. Hot Cracking (Solidification Cracking)

This type of cracking occurs as the weld pool solidifies and is characterized by intergranular fractures along the grain boundaries. Several factors contribute to hot cracking in aluminum welds:

- Improper Filler Metal Selection: Using a filler alloy with insufficient silicon content can increase the susceptibility to hot cracking. Silicon improves the fluidity of the weld pool and reduces the solidification range.

- High Welding Speeds: Rapid solidification due to high welding speeds can lead to increased stress on the solidifying weld metal, promoting crack formation.

- Excessive Heat Input: While sufficient heat is necessary for fusion, excessive heat input can create a wide, shallow weld pool that is more prone to shrinkage stresses during solidification.

- Joint Design: Joint designs that restrict shrinkage or create stress concentrations can significantly increase the risk of hot cracking.

- Presence of Low-Melting-Point Eutectics or Impurities: Certain impurities or the formation of low-melting-point phases at the grain boundaries can weaken the solidifying weld metal.

2. Cold Cracking (Hydrogen-Induced Cracking)

This type of cracking typically occurs after the weld has completely solidified and is often associated with the presence of hydrogen in the weld metal. Contributing factors include:

- Moisture and Contaminants: Moisture on the base metal, filler metal, or even in the shielding gas can introduce hydrogen into the weld pool. Oxides and other contaminants on the aluminum surface can also trap moisture.

- Porosity: Porosity in the weld can create voids where hydrogen can accumulate, increasing the risk of cracking.

- High Residual Stresses: High residual stresses in the weldment, often due to constrained joints or uneven heating and cooling, can exacerbate the effects of hydrogen embrittlement.

3. Other Potential Causes

Poor joint preparation, such as inadequate cleaning of the tenacious aluminum oxide layer, can lead to incomplete fusion and potential defects that may propagate into cracks. Insufficient shielding gas coverage can allow atmospheric contamination, leading to porosity and weakened welds. Improper welding techniques, such as an excessively long arc length or incorrect travel angle, can also contribute to weld defects and increase the likelihood of cracking.

How to Prevent Cracks in Aluminum TIG Welding

Preventing cracks in aluminum TIG welds requires meticulous attention to detail throughout the entire welding process. Implementing the following best practices can significantly minimize the risk of cracking:

- Material Preparation: Thoroughly clean the base metal and filler rod immediately before welding to remove all traces of oxides, grease, moisture, and other contaminants. Mechanical cleaning methods like wire brushing with a stainless steel brush are often necessary to break through the aluminum oxide layer.

- Filler Metal Selection: Always choose a filler alloy that is specifically designed for the base aluminum alloy being welded and consider using filler alloys with a slightly higher silicon content (e.g., 4043 or 4643 for many aluminum alloys) to improve weld pool fluidity and crack resistance.

- Welding Parameters: Carefully control heat input by adjusting amperage and travel speed. Aim for a balanced heat input that ensures adequate penetration without excessive widening of the weld pool. Consider using pulsed TIG welding, which can reduce average heat input while maintaining penetration and improving weld quality. Maintain a consistent and short arc length.

- Shielding Gas: Use high-quality, dry, and pure argon shielding gas with an appropriate flow rate to ensure complete coverage of the weld pool and prevent atmospheric contamination.

- Joint Design: Design joints to minimize stress concentrations and allow for adequate shrinkage during solidification. Consider using wider included angles for butt joints and avoiding overly constrained joint configurations.

- Preheating: For thicker aluminum sections, preheating to a moderate temperature (typically between 200-400°F or 93-204°C) can help reduce thermal gradients, slow down the cooling rate, and minimize shrinkage stresses, thereby reducing the risk of hot cracking.

- Post-Weld Cleaning: After welding, thoroughly clean the weld area to remove any welding residue or discoloration.

Aluminum TIG welding, while offering exceptional precision and quality, demands a thorough understanding of the material properties and potential pitfalls. Recognizing the weldability characteristics of different aluminum alloys and the primary causes of cracking – hot cracking during solidification and cold cracking due to hydrogen embrittlement – is fundamental. By adhering to best practices in material preparation, filler metal selection, welding parameters, and joint design, welders can significantly mitigate the risk of cracking and master the art of producing strong, durable, and aesthetically pleasing aluminum TIG welds, unlocking the full potential of this versatile material across a wide spectrum of applications.