Due to the application of coatings, aluminum wires acquire new advantages and slowly become bare aluminum wires. Coating of plastic, PVC, and copper makes the wires easier to use in construction, electronics, and many other fields.

Deciding on a particular project, one comes across a great number of wires. This makes it important to understand the key concepts of every wire. Thus the aim of this article is to give the reader some vital information about aluminum wires and their types.

Why are Coatings Important on Aluminum Wire?

The use of bare aluminum poses several challenges that limit its use in a wide range of mechanical and electrical applications. Take for instance an aluminum wire in a damp setting. The wire would corrode very quickly forming a resistive oxide layer which would impede any electrical flow and compromise the wire’s structural integrity. Coatings are crucial for transforming bare aluminum wire into a dependable and resilient component primed for specific applications.

The actions of coatings are numerous. Coatings protect against abrasion, and serve as an insulator which halts any unwanted short circuits. The coatings also protect against moisture, chemicals, UV light and extreme temperatures. Without aluminum wires, these components would provide limited practical utility which makes coated aluminum wires essential in engineering. Thus, encasing coatings understand how coated aluminum wires are practical for modern engineering.

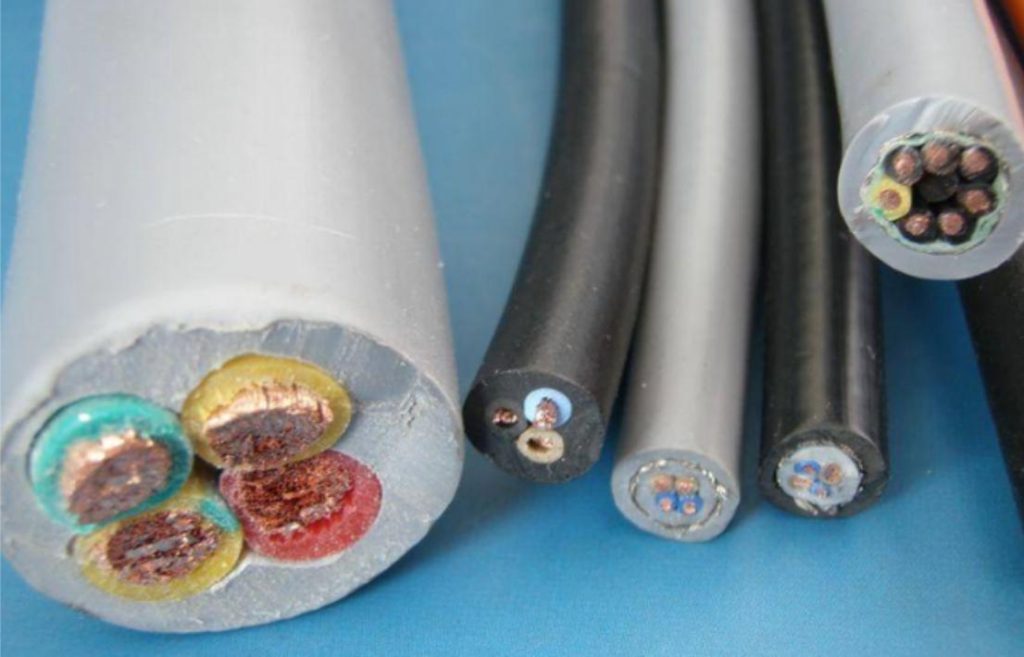

Plastic, PVC, and Copper Coatings Over Aluminum Wires

The performance of coated aluminum wire is highly influenced by the choice of the coating material in terms of functionality, reliability, adaptability to environmental conditions and longevity. Let’s discuss the differences of each coating material || plastic, PVC and copper || in greater detail.

Plastic Coated Aluminum Wire

Characteristics and Advantages

Plastic-coated aluminum wire commonly pertains to aluminum wire insulated with polymers such as polyethylene (PE) and polypropylene (PP). These plastics are chosen because of their light weight, good electrical insulation and flexibility. For example, polyethylene has good dielectric strength, which means it can withstand a lot of electric stress without failing. This makes it a good general purpose insulator. The dielectric strength of polyethylene contributes to a wire’s overall reliability and makes it cost-effective.

With respect to advantages, having a low cost makes plastic coatings appealing for projects where cost is a major factor. Aside from low cost, plastic coatings have a nice tactile feel and are simple to strip during installation. As an example, consumer electronics and small appliances have minimal requirements for extreme heat or chemical resistance, which makes them right for basic plastic coatings. Their low cost and light weight is a huge factor. Moreover, their flexibility aids in routing through tight spaces.

Limitations and Considerations

Plastic-coated aluminum wire possesses some clear disadvantages. They usually have poorer temperature resistance when compared to PVC or other high-performance specialized polymers. Take for instance PE; it would begin to deform around 70 to 80°C and would certainly not be useful around engines or any other components that produce heat.

Moreover, plastic coatings are often prone to UV sunlight exposure, rendering them brittle and prone to cracking. Their ability to withstand chemicals is often not very good either, making them poorly suited for environments with exposure to oils, solvents, or other corrosive materials. They need to be very careful with regard to the working environment, else the wire would be susceptible to failure too soon. It is quite predictable that the insulation would be compromised within years if a plastic-coated wire was used outdoors without UV stabilizers.

Common Uses

- Internal wiring for appliances: Household devices such as blenders and toasters use plastic coated aluminum wire for internal connections where temperature and environmental exposure do not exceed moderate levels.

- Automotive wiring harnesses (non-engine bay): For dashboards, door panels, and other lighting circuits where exposure to high temperatures and chemicals is not a concern, the plastic coated wire’s flexibility and cheaper price is an advantage.

- Low-voltage lighting: For its simplicity and low price, plastic coated aluminum is employed for LED strip lighting or other decorative lighting.

- Hobbyist electronics: For simple electronic circuits and prototyping, this aluminum is a common choice because of its price and ease of use.

PVC Coated Aluminum Wire

Features and Benefits

Polyvinyl chloride (PVC) serves as the polymer for coating the aluminum wire, as it is one of the most flexible thermoplastic polymers because of its good combination of properties. PVC’s most notable property for use in construction and industrial applications is the fact it is flame retardant. The coating will burn, but when the flame source is removed, it will extinguish on its own. This is important for safety, durability, and construction of the buildings and plants. Another positive for PVC is the chemically correlated safety for moisture, oils, and a wide variety of chemicals.

Moreover, PVC maintains its advantages above general plastics when it comes to temperatures. Its scope extends from -20°C to 105°C, especially for the less demanding applications. Its construction-grade PVC jacket on the wires in question is a good example, as the THHN/THWN-2 cable is used in conduits where the conditions are a bit above normal. Its electrical insulation efficiency makes it ideal for situations under stress.

Limitations and Considerations

Aluminum wire coated in PVC exhibits widespread versatility; however, it does not come without its limitations. Its halogen content is particularly concerning. PVC’s halogen content is particularly concerning. In the event of a fire, PVC can yield Hydrogen Chloride gas which is corrosive and toxic and threatens both human life, and electronic machinery. This has prompted the development and use of Low Smoke Zero Halogen alternatives in environments such as data centers, trains and, public transportation where LSZH equivalents are more sensitive.

Moreover, the tendency of PVC to become brittle and stiff in low temperature conditions makes installation of the material in freezing temps daunting. For instance, a cable installer working outdoors in a cold region during the winter might find PVC coated wires more unyielding to maneuver than rubber or specially designed cold-weather jacketed cables, which are more flexible. Nonetheless, for a great number of applications, the advantages of PVC especially its chemical stability and fire resistance greatly outweigh these drawbacks.

Common Uses

- Wiring for buildings (both private and business) : Most indoor electrical wirings such as NM-B and THHN/THWN cables, are pvc insulated because the material is flame-retardant and moisture-resistant.

- Industrial control cables: PVC coated aluminum wire is very common for control cables in factories and processing plants because the wire is resistant to oils, greases and other industrial chemicals.

- Automotive engine compartments: Because basic plastics are very weak where hotter temperatures are common and exposed to oil and lubricants, PVC is favorable in these section because it is better than basic plastics.

- Power and lighting cables for outside use: Because some cables are exposed to the elements, requirements such as UV and moisture resistant are important, though some grades that are specifically manufactured for prolonged exposure to direct sunlight do exist.

- Telephone and other telecommunications cables: Telephone and other data cables for internal and external use often apply jackets made of PVC for protection and insulation.

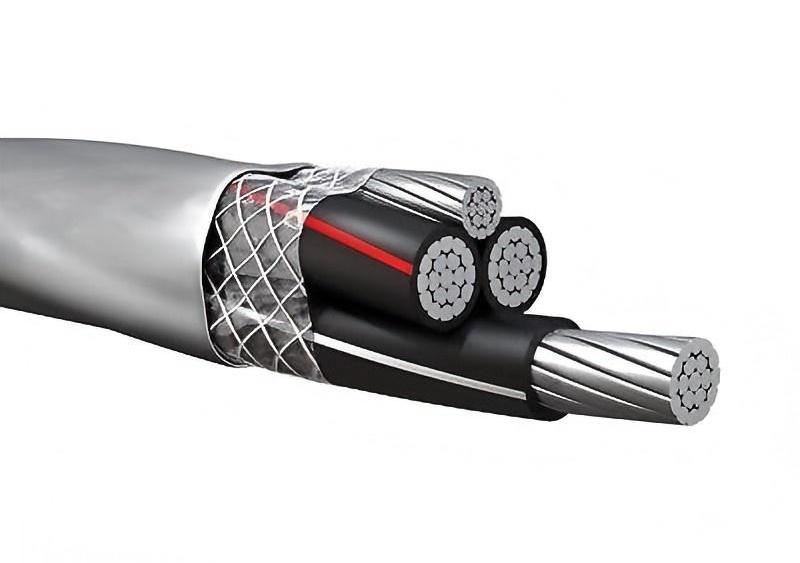

Copper Coated Aluminum Wire (CCA)

Characteristics and Advantages

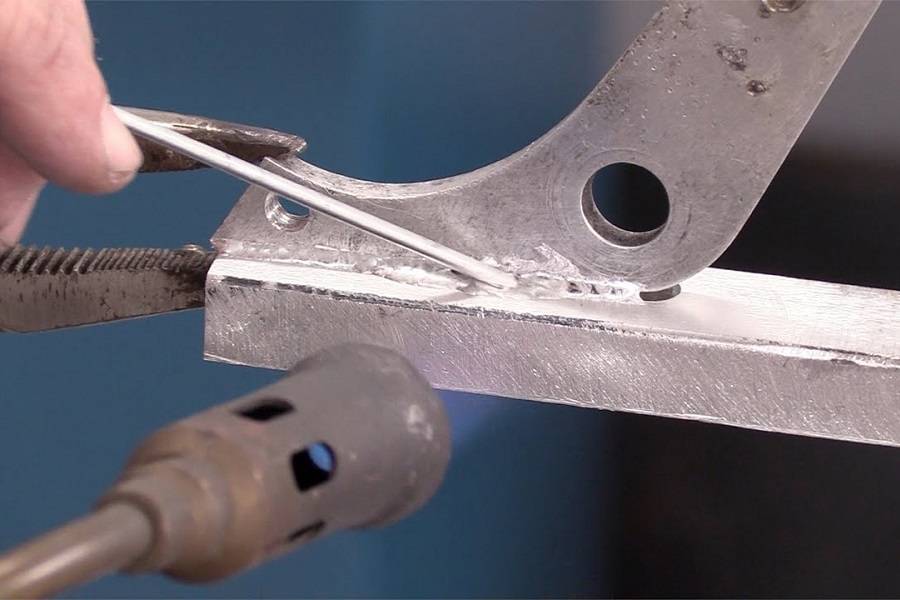

The copper coated aluminum wire CCA is an example of a unique hybrid wire, incorporating the merits of copper and aluminum. It is produced by the metallurgical process of bonding a copper layer to an aluminum core. This is not simply a plating, but a drawing process which makes the two materials form an inseparable system.

The compelling primary advantages of the copper CCA are the cost benefits and its electrical properties. It is less expensive than solid copper wire. The savings range between 30-60% with CCA retaining the advantages of copper. Most importantly, the copper is 40% lower in weight than an equal mass of copper wire. This leads to lower shipping and easier installation. Electrically, CCA exhibits a greater conductivity than bare aluminum, especially at higher frequencies CCA performs well due to the skin effect. The aluminum core reduces the cost, weight, and space needed for storage.

The soldering properties of CCA bare aluminum are exceptional, so terminations are far more dependable to engineers, which is a major practical advantage. As an example, a major telecommunications company looking to lower material cost without sacrifice in signal loss for infrastructure last-mile DSL used copper to CCA drop cables and realized significant material savings.

Limitations and Considerations

The copper coated aluminum wire offers unique advantages, yet incorporates limitations that must be recognized. It has not been designed and cannot directly replace solid copper wires in every scenario. Analogous to solid copper, CCA has increased DC resistance.

For instance, in CCA, 23 AWG has greater DC resistance than solid 23 AWG copper. Therefore, for extended lengths in direct current (DC) high-current applications, CCA must be used in a greater gauge than solid copper to mitigate voltage drop issues.

Applicable termination techniques are likewise critical. Unlike aluminum, CCA is easier to solder, but the resulting joint becomes bimetallic and must be galvanically protected. Connectors of aluminum or bimetallic nature that mitigate galvanic corrosion need to be used. Such corrosion, if not managed, can lead to increased resistance and with that, increased risk of fire over a longer duration. For instance, it was described that CCA connections are prone to failure in high vibration applications due to the use of copper-only connectors that are improperly crimped. Engineers need to ensure component interactions when specifying CCA and must provide the necessary interface to every part.

Common Uses

- Data communications cables: Ethernet cables (Cat5e, Cat6) and coaxial cables (RG-6, RG-59) employ copper coated aluminum wire as a conductor. The skin effect results in enhanced data transmission, as high frequency data utilizes primarily the copper layer, making data transmission economical.

- Audio and video cables: The fire transmission properties of CCA make it an ideal choice for speaker wire, RCA cables, and HDMI cables used in home CCA entertainment systems.

- Automotive wiring (non-critical power): CCA is suitable for wire harnesses in infotainment systems as well as non-engine bay lighting where weight is at a premium and power consumption is capped.

- Antenna wiring. CCA is used in television and radio antennas where it is superior to solid copper due to lower cost while retaining acceptable signal reception performance.

- Low-current power distribution. For short runs of wire where slight voltage drop is acceptable, CCA is a cost-effective substitute to solid copper.

Comparative Table: Coated Aluminium Wire Types

| Feature / Type | Plastic Coated Aluminium Wire | PVC Coated Aluminium Wire | Copper Coated Aluminium Wire (CCA) |

| Typical Coating Material | Polyethylene (PE), Polypropylene (PP) | Polyvinyl Chloride (PVC) | Copper (Metallurgically bonded to Aluminum core) |

| Primary Function | Basic Insulation, light protection | Insulation, Flame Retardancy, Environmental Protection | Enhanced Conductivity, Solderability, Cost/Weight Reduction |

| Cost (Relative) | Lowest | Moderate | Moderate (Significant savings vs. solid copper) |

| Weight (Relative) | Very Low | Low | Low (Approx. 40% lighter than equivalent solid copper) |

| Flexibility | High | Good (Can stiffen in cold) | Good |

| Electrical Insulation | Good | Excellent | Requires additional insulation (Copper is conductive) |

| Flame Retardancy | Poor (Often melts/burns) | Excellent (Self-extinguishing) | N/A (Conductor, requires external insulation) |

| Temperature Range | Limited (e.g., 70-80°C max for common PE) | Wide (e.g., -20°C to 105°C) | Core material dependent, conductor properties stable across temp ranges |

| Chemical Resistance | Limited (Poor against oils, solvents) | Good (Resistant to oils, many chemicals) | Excellent (Copper layer protects aluminum) |

| UV Resistance | Poor (Unless stabilized) | Good (Often UV stabilized) | Excellent (Copper is highly UV resistant) |

| Solderability | Not applicable (insulation) | Not applicable (insulation) | Excellent (Due to copper surface) |

| DC Resistance | N/A (Insulator) | N/A (Insulator) | Higher than equivalent gauge solid copper (e.g., ~1.5x) |

| High Frequency Performance | N/A (Insulator) | N/A (Insulator) | Excellent (Due to skin effect) |

| Primary Limitation | Low temp/chemical/UV resistance | Halogen release in fire, cold flexibility | Higher DC resistance than copper, specific termination needs |

Choosing the Right Coated Aluminium Wire

Optimum coated aluminum wire selection is not a universal decision; it is an intricate decision making process based on the project’s technical requirements, environmental considerations, safety standards, and cost implications. So far, we have reviewed that each variant: plastic coated aluminum wire, PVC coated aluminum wire, and copper coated aluminum wire, have their distinctive advantages and disadvantages. It is the engineer’s responsibility to assess these considerations and the targeted application and requirements. As we have already mentioned, here are some tips:

| Factors | Choosing Tips | |

| 1. Electrical Requirements | Voltage&Current | For high-current, low-frequency (DC) applications over long runs, be mindful of CCA’s higher DC resistance; you might need a larger gauge than solid copper. For low-voltage, low-current needs, plastic or PVC coated aluminum wire are often sufficient. |

| FREQUENCY | For high-frequency signals (e.g., data, audio/video), Copper Coated Aluminum Wire (CCA) excels due to the skin effect, where current predominantly flows through the conductive copper layer. For standard power transmission, this is less critical. | |

| 2. Environmental Conditions | Temperature Range | If the wire will be exposed to elevated temperatures (e.g., engine bays, industrial machinery), PVC Coated Aluminum Wire offers a wider operating range than basic plastic coatings. For extreme or low temperatures, consult specific product datasheets. |

| Moisture/Chemicals | For environments with moisture, oils, greases, or various chemicals, PVC Coated Aluminum Wire provides superior resistance. Basic plastic coated aluminum wire is generally not recommended for such exposures. CCA’s copper layer offers good corrosion resistance. | |

| UV Exposure | For outdoor applications with direct sunlight, ensure the coating is UV-stabilized. PVC Coated Aluminum Wire often has good UV resistance, while basic plastic coated aluminum wire may degrade rapidly without specific additives. CCA’s copper layer is inherently UV resistant. | |

| Flammability | In areas where fire safety is paramount (e.g., building interiors, public spaces), PVC Coated Aluminum Wire is often preferred due to its self-extinguishing properties. Consider Low Smoke Zero Halogen (LSZH) alternatives for very sensitive environments. | |

| 3. Mechanical Properties | Flexibility/Handling | For applications requiring high flexibility or ease of routing in tight spaces, both plastic coated aluminum wire and PVC coated aluminum wire generally perform well. CCA also offers good flexibility relative to solid copper. |

| Abrasion Resistance | For environments where the wire may experience rubbing or physical stress, PVC Coated Aluminum Wire typically offers better abrasion resistance than simple plastic coatings. The overall jacket thickness and material hardness play a role here. | |

| 4. Cost & Economics | Material Cost | For the most budget-sensitive projects, plastic coated aluminum wire is generally the most economical. PVC Coated Aluminum Wire offers a good balance of cost and performance. Copper Coated Aluminum Wire (CCA) provides significant material cost savings compared to solid copper. |

| Installation Cost | Consider ease of stripping, termination requirements, and wire weight. CCA’s lighter weight can reduce shipping and handling costs for large projects. Ensure you have the correct termination tools and connectors for aluminum or bimetallic conductors to prevent long-term issues. | |

| Longevity/Replacement | Invest in a wire that meets environmental demands to avoid premature failure and costly replacements. A slightly higher initial cost for the right coating can lead to substantial long-term savings through reduced maintenance and increased system uptime. | |

| 5. Regulatory Compliance | Industry Standards | Always verify that the chosen coated aluminum wire complies with relevant electrical codes (e.g., NEC in the US, IEC internationally) and industry standards (e.g., UL, CSA listings) for the specific application. This is non-negotiable for safety and project approval. |

| Environmental Regs | Be aware of regulations like RoHS (Restriction of Hazardous Substances) if applicable, particularly when considering PVC in certain markets due to its halogen content. | |

Coated aluminum wire options—plastic, PVC, and copper—each cater to different needs and environments. By understanding their characteristics and applications, you can make an informed choice that aligns with your project’s requirements and budget. For any aluminum wire needs, please feel free to contact CHAL.