In recent years, global copper prices have shown strong volatility. On the London Metal Exchange (LME), copper has risen by more than 40% compared with five years ago, at times breaking the $10,000 per ton mark. For power infrastructure projects, this price uncertainty creates enormous cost pressure, especially for underground cables, where conductor materials alone can account for 30%–50% of total project costs.

China, like many other markets, faces a structural challenge: copper resources are relatively scarce, with reserves of only 3,494.79 tons, while bauxite reserves—used to produce aluminum—are far more abundant at 71,113.74 tons. Combined with the high dependency on imported copper, this imbalance makes it increasingly necessary to explore reliable and cost-effective alternatives.

Against this backdrop, the concept of “aluminum replacing copper” has gained increasing attention in the cable sector. By using advanced aluminum alloy conductors instead of traditional copper, projects can not only alleviate resource constraints but also achieve substantial cost savings. However, this transition is far from a simple material substitution. It requires a thorough evaluation of electrical performance, mechanical strength, connection reliability, and full lifecycle costs. This article explores the economic benefits and practical challenges of adopting aluminum conductors in underground cable systems, offering data-driven insights for project decision-makers.

Copper vs. Aluminum: The Ultimate Trade-off Between Performance and Cost

Traditional Perceptions of Performance Gaps

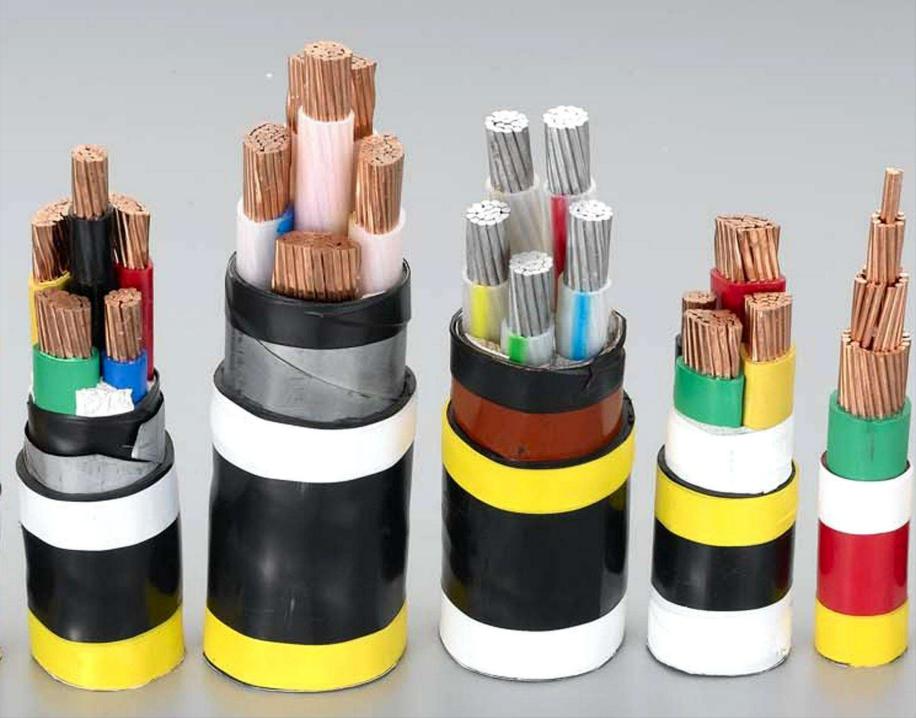

Copper has long dominated as the conductor material of choice for power cables, largely due to its outstanding electrical conductivity (the highest among commonly used metals) and superior mechanical strength. By comparison, aluminum provides only 61–66% of copper’s conductivity, meaning its current-carrying capacity is lower for the same cross-sectional area. In addition, pure aluminum has weaker mechanical strength, making it more prone to damage under frequent bending or high stress. Another challenge lies in its surface oxidation: the oxide layer that forms increases resistance, causing joints to overheat, loosen, or even fail.

These limitations historically made aluminum cables less reliable, especially at connection points. A key concern has been aluminum’s poor creep resistance—its tendency to deform slowly under long-term stress. Over time, this could cause connections to loosen, restricting aluminum’s use in underground cable applications.

Quantifying the Cost Difference

Despite these drawbacks, aluminum’s advantages in cost and weight are undeniable. The current copper-to-aluminum price ratio is roughly 4:1, making aluminum a significantly more economical option. Even after accounting for the need for larger cross-sectional areas to match copper’s current capacity, aluminum conductors can still reduce total cable costs by 30–50%.

In underground cable projects, aluminum alloy conductors typically require a cross-section 1.5 to 2 sizes larger than copper to carry the same load. However, aluminum’s density is only about one-third that of copper (2.7 g/cm³ vs. 8.96 g/cm³). As a result, aluminum cables weigh around 50% less, which translates into major savings in transportation, installation, and support structures. This lightweight advantage is particularly valuable in long-distance transmission lines or weight-sensitive installations.

Key Performance Parameters of Copper, Aluminum, and Aluminum Alloys

| Property | Copper | Pure Aluminum | Aluminum Alloy |

| Conductivity (% IACS) | 100 | 61–66 | 56–61 |

| Density (g/cm³) | 8.96 | 2.7 | 2.7–2.8 |

| Tensile Strength (MPa) | 200–250 | 70–80 | 115–195 |

| Thermal Expansion (10⁻⁶/°C) | 17 | 23.5 | 21.8–25.5 |

| Melting Point (°C) | 1080 | 660 | 660 |

Technological Advances in Aluminum Alloys

Advances in materials science have greatly improved the performance of aluminum alloys. By introducing elements such as iron, magnesium, silicon, and copper, high-performance aluminum alloys preserve aluminum’s lightweight and cost advantages while significantly enhancing mechanical strength. In particular, improvements in tensile strength and creep resistance address the historical weakness of loose connections in pure aluminum conductors.

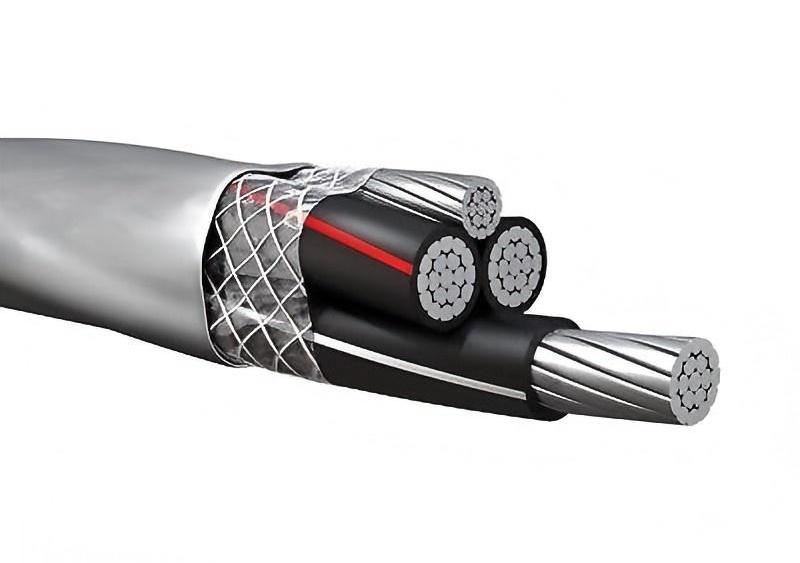

Today, 8-series aluminum alloys are the most widely used conductor materials in power cables. Compared with 1-series pure aluminum conductors, they are far less prone to creep under stress and elevated temperatures, ensuring connection reliability comparable to copper. Further innovations, such as micro-alloying with rare-earth elements (La, Ce, Er, and others), continue to refine conductivity, mechanical properties, and corrosion resistance, making modern aluminum alloy conductors a far more competitive alternative for underground cable systems.

Benefit Analysis of Aluminum Replacing Copper in Underground Cables

Aluminum substitution for copper in underground power cables offers significant economic and operational advantages, but also requires careful attention to technical and environmental factors.

1. Material Cost and Weight Savings

The most immediate advantage of aluminum is direct material cost reduction. For the same current-carrying capacity, aluminum conductors can reduce material expenses by 30–50% compared to copper. For example, in a 10 km underground cable project, replacing copper with aluminum alloy conductors can lower material costs by approximately 40%, even when the conductor cross-section is increased to meet ampacity requirements.

Two main factors contribute to this cost advantage:

- Price difference: Aluminum’s market price is roughly one-fourth of copper’s, making it significantly more economical.

- Weight reduction: Aluminum’s density is only about 2.7 g/cm³, approximately one-third of copper’s 8.96 g/cm³. At equivalent current capacity, aluminum cables weigh 50% less, reducing transportation, installation, and structural support costs. For the same weight of material, aluminum can provide nearly double the cable length compared to copper.

2. Lifecycle Cost (LCC) Considerations

While upfront costs are lower, a full lifecycle cost evaluation is essential. Aluminum’s slightly higher electrical resistance results in 2–3% more energy loss during operation than copper. In high-voltage or long-distance installations, this additional operating cost may take several years to offset the initial material savings.

However, aluminum cables offer lower installation and maintenance costs. Their light weight and improved flexibility (minimum bending radius ~7× cable diameter, versus 12–15× for copper) simplify handling, reduce labor costs by roughly 15%, and allow easier routing through conduits or tight spaces. Modern interlocked aluminum armor designs further eliminate the need for additional conduits or trays, cutting auxiliary material costs.

Additional strategic advantages include:

- Resource security: China has abundant aluminum reserves, whereas copper is heavily imported (~85%), giving aluminum a supply chain advantage.

- Environmental benefits: Aluminum production emits over 70% less CO₂ than copper. In a 100 MW solar plant, using aluminum conductors reduces lifecycle carbon emissions by about 35%.

- Installation efficiency: Lighter and more flexible aluminum alloys facilitate transportation, storage, and faster installation.

3. Technical Feasibility in Underground Applications

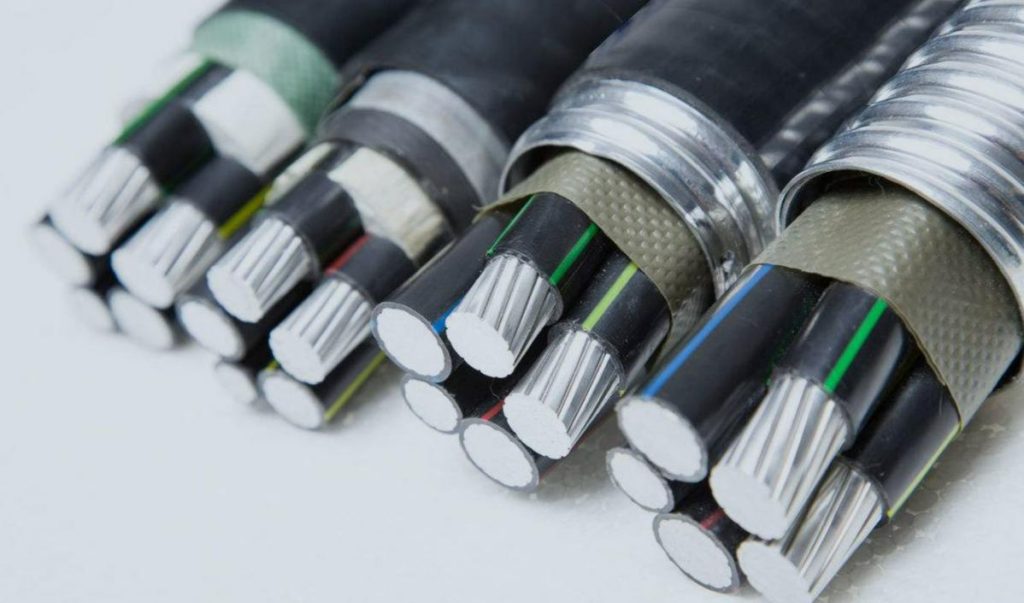

Underground cables face high humidity, limited maintenance access, and mechanical stress, posing higher requirements for conductor materials. Aluminum replacement is technically feasible in several areas:

- Electrical performance: Domestic aluminum-core cables are fully localized in China for voltages up to 35 kV, and are widely applied in power distribution, construction, and rail transit. Internationally, aluminum cables are deployed up to 380 kV for land projects and are being tested in 500 kV DC submarine cables, proving their reliability in medium- and low-voltage applications.

- Mechanical performance and durability: Modern aluminum alloys, combined with compacted conductor technology (compression ratio ~0.92), reduce cable diameter while maintaining conductivity. Interlocked “S”-shaped armor forms a self-locking layer, significantly enhancing mechanical strength and durability.

- Environmental adaptability: Advanced gradient composite protective systems prevent ion migration at the base layer and provide surface-level corrosion resistance, enabling reliable performance in coastal, high-salinity, and humid underground environments.

4. Challenges and Mitigation Strategies

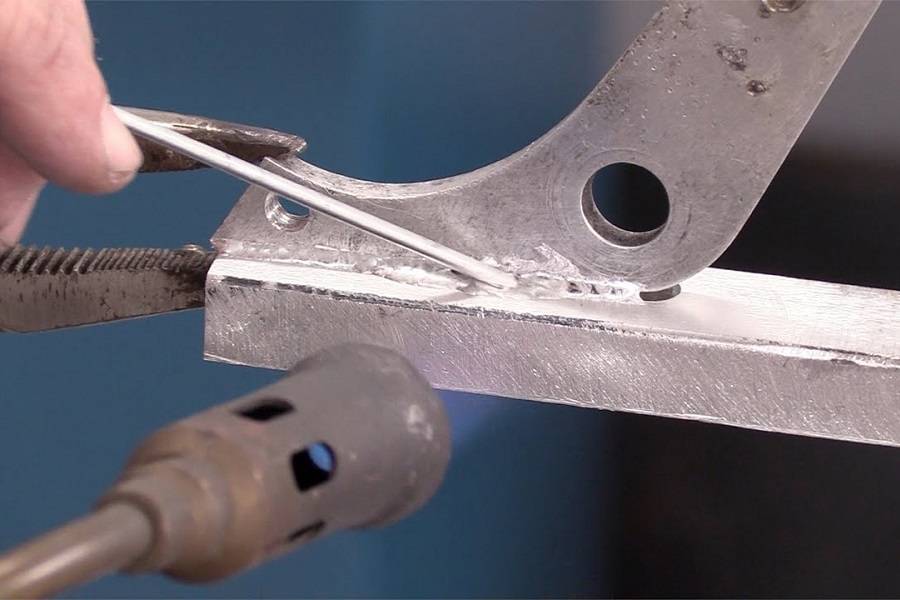

- Connection reliability: Aluminum oxidizes quickly, forming a hard, high-resistance oxide layer. Faults often occur at joints or terminals. Solutions include special copper-aluminum transition connectors and anti-oxidant compounds to maintain stable electrical contact.

- Electrochemical corrosion: Contact with dissimilar metals in humid conditions can accelerate corrosion. Mitigation involves isolation measures such as coated connectors or protective compounds.

- Creep under sustained stress: Aluminum deforms gradually under long-term pressure, potentially loosening connections. Using high-performance aluminum alloys improves creep resistance.

- Installation complexity: Aluminum jointing requires additional steps compared to copper, including oxide removal and application of protective compounds. Dedicated crimping tools, step-by-step guides, and installer training are crucial.

- Industry perception: Historical issues with household aluminum wiring in the 1960s–70s have left negative impressions. Sharing modern case studies and technology advancements is key to building confidence in aluminum conductors.

Aluminum substitution in underground cables is both cost-effective and technically viable for medium- and low-voltage applications. High-performance aluminum alloys provide sufficient electrical, mechanical, and environmental performance, while reducing material weight and project costs. For higher-voltage installations, ensuring reliable connections, standardized certifications, and long-term creep resistance remains critical to achieve safe and efficient operation.

| Category | Copper | Aluminum / Aluminum Alloy |

| Material Cost | High | Low (≈30–50% savings) |

| Density / Weight | 8.96 g/cm³ | 2.7–2.8 g/cm³ |

| Electrical Conductivity (% IACS) | 100 | 56–66 |

| Mechanical Strength / Tensile (MPa) | 200–250 | 115–195 |

| Creep Resistance | Excellent | Moderate (improved in high-performance alloys) |

| Flexibility / Installation | Moderate | High |

| Environmental Resistance | High | High (with gradient composite protection) |

| Connection Reliability | High | Good with proper connectors & anti-oxidant compounds |

| Lifecycle Cost (LCC) | Higher material cost, lower operational losses | Lower material cost, slightly higher energy loss |

| Resource & Sustainability | Limited copper supply, high import dependence | Abundant aluminum, lower carbon emissions |

| Voltage Applicability | All ranges | Medium- & low-voltage mature; high-voltage expanding |

Material Selection for Underground Cables

Selecting the right conductor material for underground cables requires balancing electrical performance, mechanical strength, cost, installation requirements, and environmental conditions. While copper remains the standard choice for many applications, modern aluminum alloys offer a cost-effective alternative for medium- and low-voltage projects, especially where weight and installation efficiency are important.

| Parameter | Copper | Aluminum / Aluminum Alloy | Recommendation / Notes |

| Voltage Range | All voltages | Medium- & low-voltage mature; high-voltage applications expanding | Use aluminum for ≤35 kV; consider alloy type for higher voltage |

| Current-Carrying Capacity | Standard | Requires 1.5–2 size increase | Ensure ampacity calculations account for cross-section change |

| Weight | Heavy | ~50% lighter | Lighter cables reduce transport and installation costs |

| Tensile Strength | 200–250 MPa | 115–195 MPa | High-performance alloys sufficient for underground stresses |

| Creep Resistance | Excellent | Moderate, improved with alloys | Essential for long-term joint reliability |

| Flexibility / Bending Radius | Moderate | Better (~7× diameter) | Easier installation in tight conduits or long runs |

| Environmental Resistance | High | High with gradient protection | Suitable for high humidity and coastal conditions |

| Installation & Connection | Standard | Requires transition terminals and anti-oxidant compounds | Proper tools and trained personnel recommended |

| Cost | High | Lower (~30–50% material savings) | Aluminum advantageous for budget-sensitive projects |

| Sustainability | Moderate | High (lower CO₂, abundant) | Aluminum offers resource security and environmental benefits |

Selecting the right conductor for underground cables depends on voltage level, load requirements, mechanical stress, and environmental conditions. Copper offers excellent conductivity, high tensile strength, and long-term stability, making it ideal for high-voltage or long-distance projects.

Modern aluminum alloys, however, provide sufficient electrical and mechanical performance for medium- and low-voltage applications, while offering 30–50% lower material cost and up to 50% weight reduction, which reduces transportation and installation expenses. With proper connectors, anti-oxidant compounds, and trained installation practices, aluminum cables can achieve reliable, long-lasting performance even in humid or corrosive underground environments.

For projects seeking a cost-effective and sustainable solution, CHAL offers high-quality aluminum alloy conductors that meet international standards, ensuring both performance and reliability in underground cable applications.