Welding aluminium and welding steel are completely different things. It’s not just a matter of how you do it. Metals themselves behave differently due to their special physical and chemical properties. What is the greatest secret to achieving this? Select the appropriate aluminum MIG welding wire. This is not merely a filler that you randomly burn through; it actually has a huge impact on the strength, cleanliness and durability of the weld. If your work involves aluminium, you must know the main types, such as 5356,4043 and 5183 aluminium MIG wires. They may look very similar, but they are designed for different tasks!

Core Characteristics and Challenges of Aluminum Welding

If you want to do a good job in welding aluminium, you really need to know what makes it a bit tricky. These quirks are not random – they actually affect the way we choose and use welding wire.

- Rapid Oxidation: We can observe that when aluminum is exposed to the air after being humidified, the first layer that appears is an aluminum oxide layer (Al2O3 oxide layer) that is dimensionally stable due to the agriclimatic conditions. Subsequently, the oxide layer gets transformed into an inhibition layer that is aluminizing on the aluminum. The aluminum oxide layer appears to create a barrier, which is an obstacle to welding due to the inclusions from the oxide layer that are present.

- High Thermal Conductivity: Another major feature of aluminum is its significant property of being thermally conductive, which allows for cooling that is relatively rapid. The greatly thermally conductive aluminum has to be supplied with a certain quantity of heat for it to be in a liquid state, whereby the amount of heat supplied has to be much more than that supplied to steel.

- High Coefficient of Thermal Expansion: The third property of aluminum is that it undergoes major deformations, which occur greatly. Due to the high deformations and flexible properties, welded pieces of structures tend to warp and are highly likely to sustain high stress after cooling.

- Big Differences in Hydrogen Solubility: In the case of welding, molten aluminum is capable of absorbing large quantities of hydrogen, and when the alloy solidifies, very little is captured. The presence of hydrogen gas bubbles causes porosity, which is a major issue when the solidifying weld pool consists of trapped hydrogen.

- No color change: Unlike steel which emits red light before melting, aluminum has no visual color change, making it difficult to determine the temperature and increasing the risk of burning through.

These factors make the selection of filler metal not merely a matter of strength, but one of the issues in managing the welding process itself.

Classification of Aluminum MIG Welding Wires

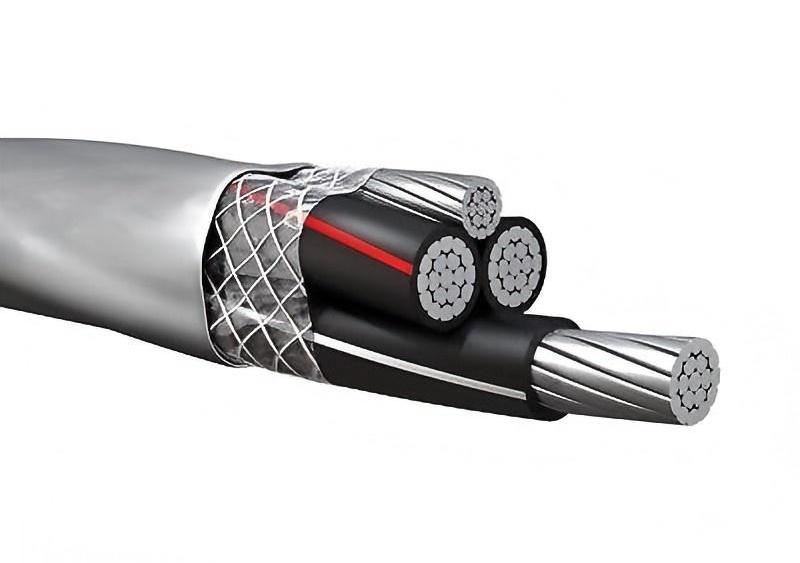

When we’re talking about aluminum MIG wires, they usually fall into two main categories depending on what they’re made of and how they’re used.

1. Pure Aluminum and Non-Heat-Treatable Alloy Wires

These are for welding pure aluminum and alloys that can’t be heat-treated to make them stronger—like the 1000, 3000, and 5000 series.

ER1100 Aluminum MIG Wires: This isn’t super strong, but great for heat and electric conduction. Adds great support against corrosion. They include electrical bus bars and chemical equipment.

ER4043 Aluminum MIG Wires: Known as the most versatile and popular choice. This is an aluminum-silicon wire with the inclusion of 5% silicon.

- Pros: The silicon also encourages the weld pool to become more fluid, which is a plus in making clean beads. Furthermore, the weld can also prevent hot cracking, which helps a lot when welding 6000 series alloys or cast aluminum.

- Cons: The resulting weld appears dark gray, resulting in the anodized layer, and increases the contrast with the base metal, which can be an issue for optical appeal.

- Uses: Works perfectly with 6000 series alloys like 6061 or 6063 cast aluminum, and also 1000 and 3000 series.

2. High-Strength Aluminum MIG Wires

These contain magnesium as the main alloying element and are built for jobs where you need more strength and better corrosion resistance.

ER5356 Aluminum MIG Wire: This is the other go-to option—right up there with ER4043. It’s an aluminum-magnesium wire with around 5% magnesium.

- Pros: stiffer than ER4043. Other factors include flexibility, rust resistance, and match black anodized aluminum.

- Cons: smooth ball of weld and possibly different. Nasty weld if moisture, oil, or dirt contaminates the metal or wire.

- Uses: This is the preferred wire for 5000 series alloys (5083 or 5052, especially for marine use), ship and pressure vessels, truck frames, and bikes.

ER5183 Aluminum MIG Wire: This wire is a more magnesium and manganese rich ER5356. This is more suited for high magnesium alloys 5083, which are common in shipbuilding and heavy duty structures.

ER5556 Aluminum MIG Wire: This wire for welding is one of the most durable aluminum filler wires available. Use it for applications that require withstanding high stress and need maximum strength in the weld.

How to Select the Right Aluminum MIG Welding Wire

Choosing the right aluminum MIG welding wire isn’t just a shot in the dark—there are a few important things you should consider.

1. Base Metal Composition: This is the main thing to know. You most definitely want your filler wire to match the base metal composition. A filler wire from the same series of alloys as the metal you’re welding should be used. Like, if you’re using a 5xxx alloy, just get a 5xxx wire.

2. Application Requirements:

- Strength: If the part is to be subjected to forces and must be strong, as in a structural member, strong wires such as ER5356 or ER5183 should be used as they perform better.

- Crack Resistance: Welding cast aluminum or parts that, once welded, do not allow much movement? These tend to crack. In that case, ER4043 is a much better option.

- Anodizing: In the case of a finished piece that is to be anodized, to protect from corrosion or for aesthetics, the color of the anodized part matters. ER5356 and other 5xxx series wires anodize to a bright, silvery color, which is desirable. ER4043, on the other hand, anodizes to a dark color, which is the most undesirable situation.

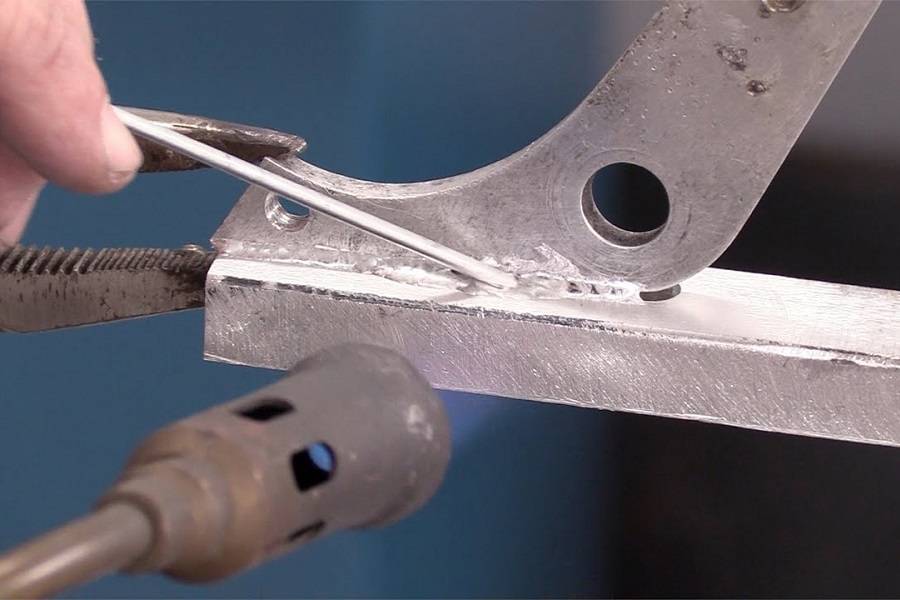

3. Welding Method: Being that it is MIG welding, a spool of wire is continuously fed. That expedites the process considerably, particularly on materials of moderate to great thickness. Everything listed above pertains to MIG. That is why it is so widely used in fabrication shops and manufacturing.

Common Pairings (Quick Guide):

- General purpose jobs (like welding 6061-T6) involve two options. While ER4043 is easier and flows, ER5356 is considerably stronger. Choose based on preference.

- Marine grade aluminum (like 5083) is best suited with ER5356 or ER5183 because they are compatible with salt water and extremely strong.

- Pure aluminum (like 1070) has to be ER1100 because it is the only compatible type, and it does not lose any conductivity.

- For automotive or bicycle frames, ER5356 is the best selection because it is tough, neat, and lightweight, which is very trustworthy for strong and durable constructions.

Summary Comparison: ER4043 vs. ER5356

| Characteristic | ER4043 | ER5356 |

| Alloy Type | Aluminum-Silicon | Aluminum-Magnesium |

| Tensile Strength | Medium | Higher |

| Weld Pool Fluidity | Excellent | Good |

| Resistance to Cracking | Excellent | Good |

| Anodizing Color Match | Poor (Dark Gray) | Good (Light/White) |

| Primary Use | 6000 Series, Castings | 5000/6000 Series, Structural, Anodized Parts |

As a concise summary for this module, mastering aluminum MIG welding boils down to understanding filler wires thoroughly. Use ER4043 for easy and smooth welds. However, for added strength and a cleaner look, ER5356 should be used. The key is to choose the wire depending on the specific task, and the requirements to be achieved. In addition to wire selection, proper cleansing and technique will yield welds which are the epitome of strength, durability, and welding proficiency.