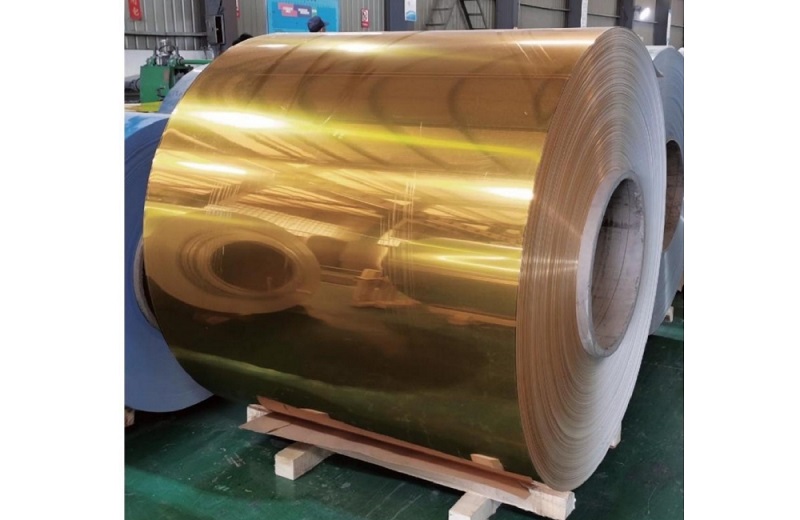

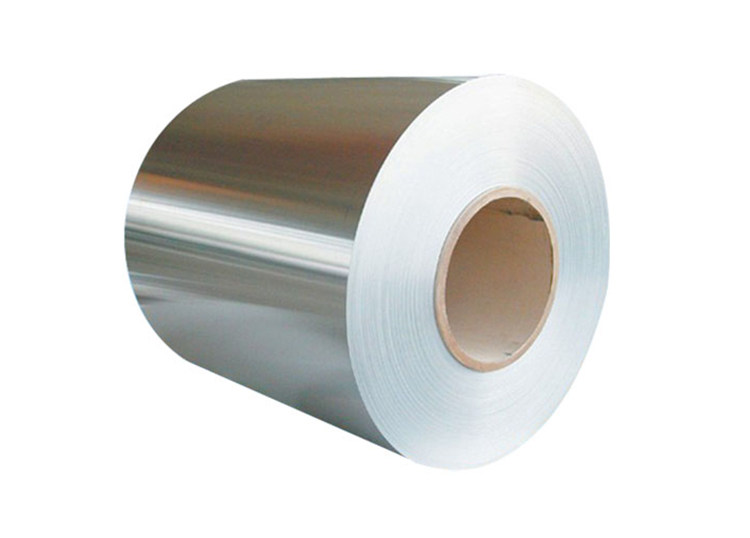

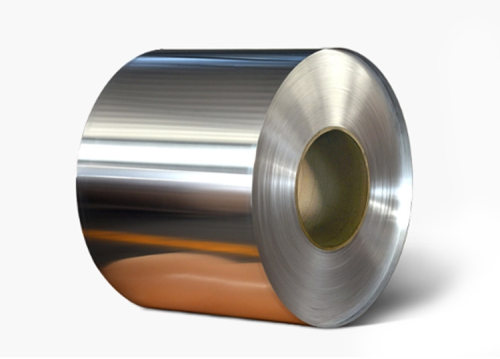

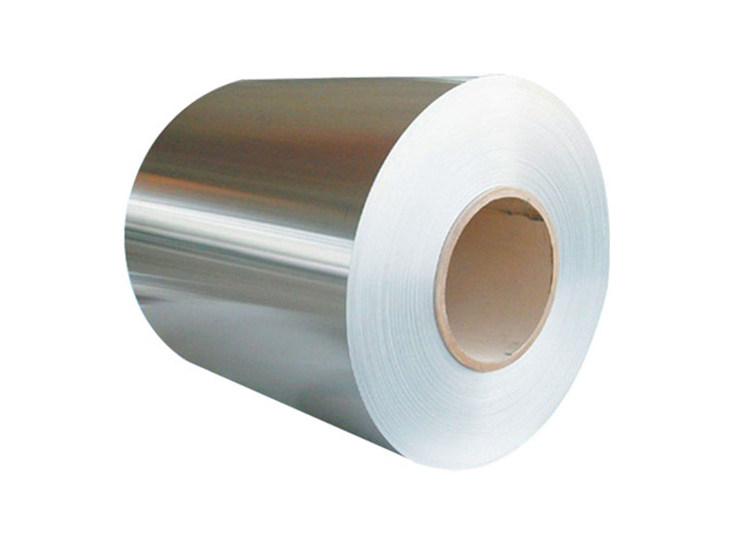

Mirror Color Coated Aluminum Coil

Color-coated mirror aluminum coil selects high-purity aluminum alloys such as the 1100, 3003, and 3105 series. We promise a purity of 99.8%, a mirror reflection rate of more than 85%, and a clarity of 94%. Adopting special processing technology, the surface effect of color-coated mirror aluminum can achieve the quality effect of imported mirror aluminum.

Applications of Mirror Color Coated Aluminum Coil

- Construction: Aluminum composite panel, aluminum honeycomb panel, Roofing corrugated sheet, fireproof panel, aluminum ceiling, shutters, rolling shutter door, garage door, canopy, gutter;

- Sub-appliances: computer case, electrical panel;

- Others: Lighting, furniture, solar energy, air conditioning ducts, etc.

CHAL’s coated aluminum coll production line represents the most reliable, energy-efficient, and environmentally friendly production operations while ensuring quality. The production line integrates the advantages of all modern coil coating technology, from flat aluminum plate cleaning to pre-treatment to painting, and drying this series of processes, each step of the painting line is a demonstration of technology and quality. The coated mirror aluminum coil is easy to process and widely used.

Performance Parameters of Mirror Color Coated Aluminum Coil

| Item |

Thickness

(mm)

|

Width

(mm)

|

Reflectance | Diffuse Reflectance | Direct Reflectance | Degree of Imaging |

| Data | 0.20-0.80 | Less than 1600 | >85% | <20 | >80 | 92 |

| Tolerance | ±0.02 | ±2 | ±1 | ±0.5 | ±1 | ±2 |

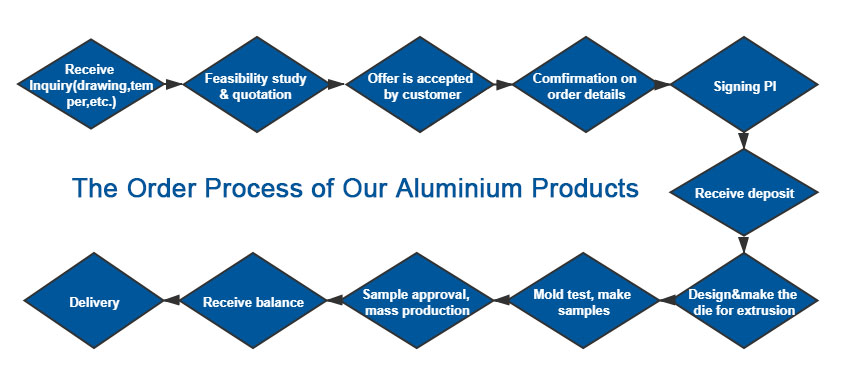

The Order Process of Mirror Color Coated Aluminum Coil