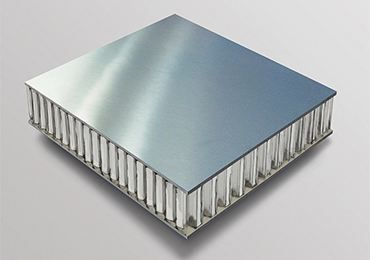

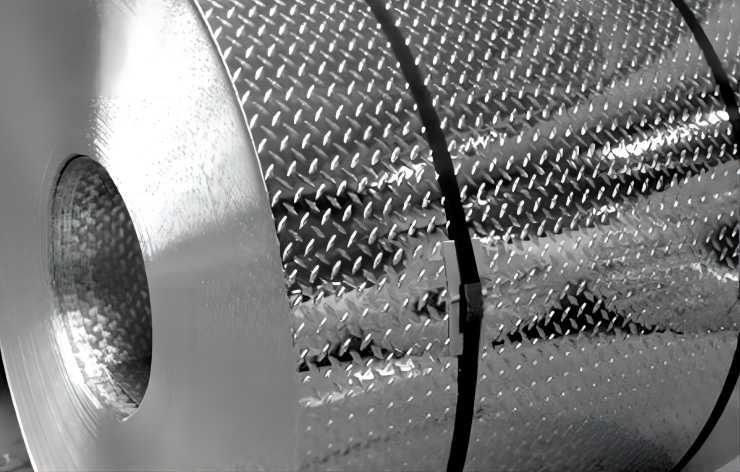

Aluminum checker plates are a popular choice in various industries due to their durability, corrosion resistance, and anti-slip properties. However, when it comes to selecting the right aluminum alloy for your specific checker plate needs, you may find yourself at a crossroads. Two commonly used alloys for checker plates are 3003 aluminum and 5052 aluminum. In this article, we will explore the characteristics of these alloys and help you make an informed choice between 3003 aluminum and 5052 aluminum for your checker plate applications.

What is 3003 Aluminum?

3003 aluminum is a versatile alloy known for its excellent formability and moderate strength. It is often selected for applications where corrosion resistance and ease of shaping are essential. Here are some key characteristics of 3003 aluminum:

1. Formability:

3003 aluminum exhibits exceptional formability, making it ideal for checker plates that require complex shapes or deep drawings. This attribute ensures that the plates can be easily tailored to fit specific designs and patterns.

2. Corrosion Resistance:

While not as corrosion-resistant as 5052 aluminum, 3003 aluminum still offers reasonable protection against rust and oxidation. It performs well in indoor and moderately corrosive environments.

3. Strength:

3003 aluminum provides moderate strength, making it suitable for lightweight yet sturdy applications. It’s often chosen for projects where structural integrity and weight considerations are important.

What is 5052 Aluminum?

5052 aluminum, on the other hand, is celebrated for its outstanding corrosion resistance and high strength. It is a preferred choice for checker plates in demanding environments. Here are some key characteristics of 5052 aluminum:

1. Formability:

While not as formable as 3003 aluminum, 5052 aluminum is still reasonably malleable. It can be shaped and molded for checker plate applications but may require more effort compared to 3003.

2. Corrosion Resistance:

5052 aluminum is renowned for its exceptional corrosion resistance. It thrives in marine and outdoor environments, where exposure to moisture, saltwater, and harsh weather conditions is common.

3. Strength:

5052 aluminum offers higher strength compared to 3003 aluminum, making it well-suited for heavy-duty applications. Its robustness ensures long-term durability in high-stress environments.

3003 Aluminum vs. 5052 Aluminum: Which Is Right for You?

The choice between 3003 aluminum and 5052 aluminum for your checker plate needs depends on several factors:

1. Environmental Conditions of 3003 vs. 5052

- If your checker plates will be exposed to moisture, saltwater, or harsh weather conditions, 5052 aluminum is the superior choice. Its exceptional corrosion resistance ensures longevity in challenging environments.

- For indoor applications with less exposure to corrosive elements, 3003 aluminum is a cost-effective solution that offers excellent formability and adequate corrosion resistance.

2. Formability vs. Strength of 3003 vs 5052

- If your project requires intricate designs, deep drawings, or complex shapes, 3003 aluminum shines with its outstanding formability.

- For heavy-duty applications that demand superior strength, 5052 aluminum provides the necessary robustness.

3. Cost Considerations of 3003 vs. 5052

- If budget constraints are a concern, 3003 aluminum is often more cost-effective than 5052 aluminum.

4. Weight Considerations of 3003 vs. 5052

- Consider the weight requirements of your application. Both alloys are relatively lightweight, but if you need a balance between strength and weight, 5052 aluminum might be the preferred choice.

Conclusion

In conclusion, the choice between 3003 aluminum and 5052 aluminum for your checker plate needs hinges on the specific demands of your project. Both alloys have their strengths and are suitable for different scenarios. By assessing your environmental conditions, formability requirements, budget, and weight considerations, you can confidently select the right aluminum alloy for your checker plate application. Whether it’s 3003 aluminum for its versatility or 5052 aluminum for its robustness, both alloys offer excellent performance and durability in their respective domains.