Aluminum, nature’s gift of lightweight strength and malleability, reigns supreme in a diverse realm of applications. From soaring skyscrapers to intricate car parts, this metal shapes our world in countless ways. But within the construction and design industry, two distinct forms of aluminum – aluminum veneer and aluminum sheet – often spark confusion. Choosing between these versatile materials hinges on understanding their nuances. In this article, we will delve into the fascinating world of aluminum, unveiling the distinct personalities of veneer and sheet.

What is Aluminum Veneer?

Aluminum veneer is a single sheet of aluminum alloy, celebrated for its remarkable features. Its durability and weather resistance make it a preferred choice for various architectural applications. Being lightweight and flexible, aluminum veneer offers unparalleled formability, allowing it to be shaped into diverse configurations. The material boasts an extensive range of finishes and colors, making it a favorite for aesthetic purposes. Additionally, aluminum veneer is fireproof and recyclable, contributing to its appeal in sustainable construction practices.

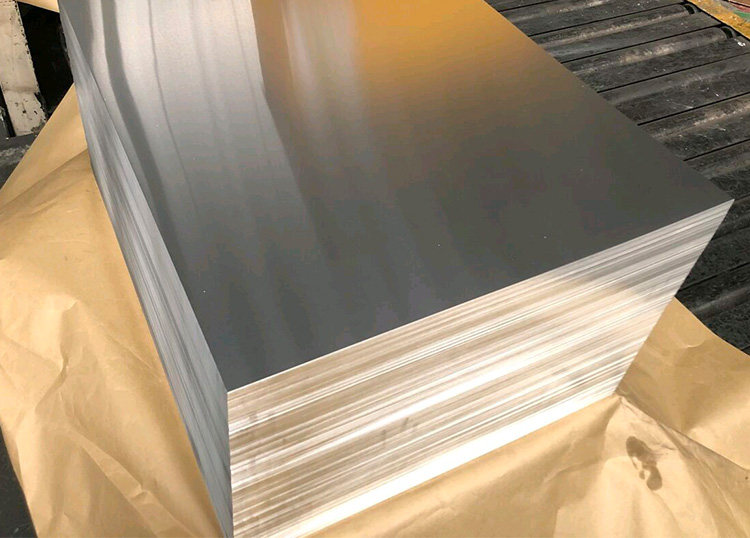

What is Aluminum Sheet?

Similar to veneer in composition but often thinner and less rigid, aluminum sheet finds application in roofing, siding, cladding, ductwork, ventilation systems, and even automotive and aerospace sectors. Its versatility is evident in its wide range of uses, making it a practical choice for both functional and decorative applications.

Key Differences between Aluminum Veneer and Aluminum Sheet

Manufacturing Processes

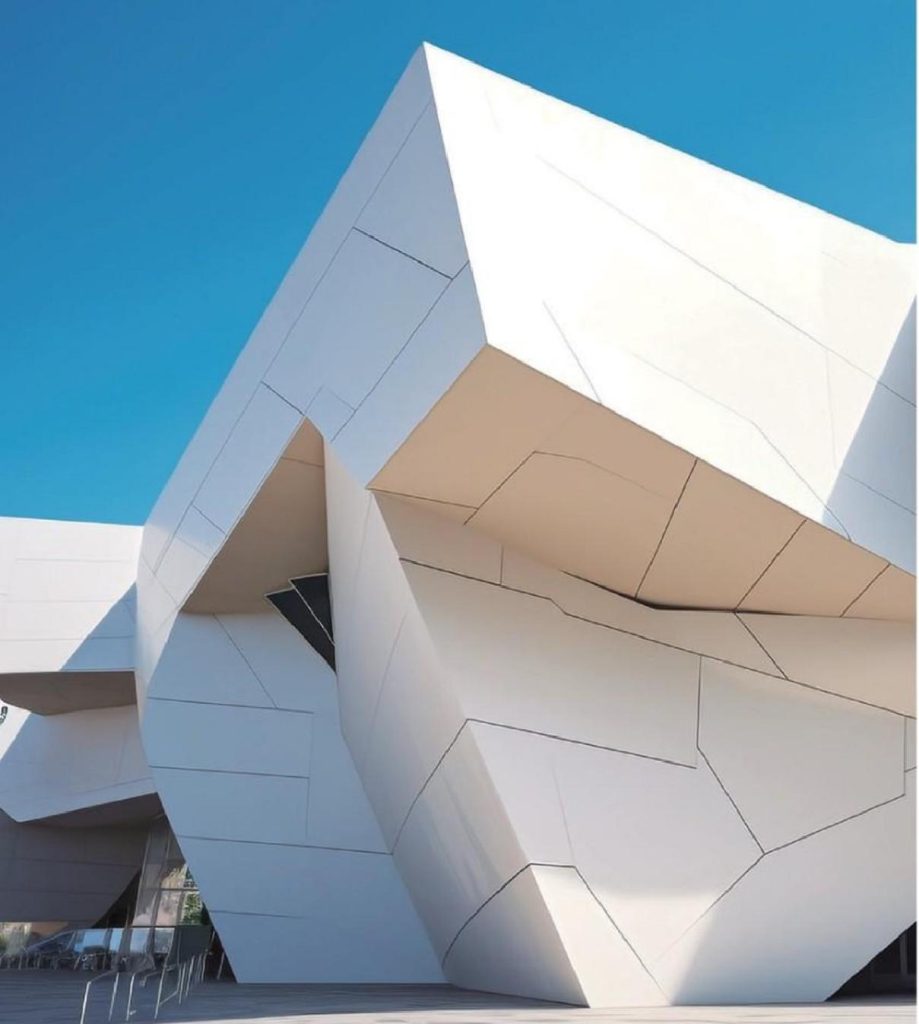

Aluminum Veneer: Embraces cutting-edge technology like computer-controlled bending (CNC) and thermoforming. CNC machines precisely guide the sheet’s movement, while heat strategically applied sculpts it into complex shapes. This transformative process allows veneer to embody the architect’s vision, from bold geometric forms to delicate curves.

Aluminum Sheet: Relies on a tried-and-true method called rolling. The aluminum alloy is fed through a series of rollers, each progressively thinning and flattening it until the desired thickness is achieved. This dependable process ensures consistent quality and makes sheet aluminum a versatile material for a wide range of applications.

Dimensional Differences

Aluminum Veneer: Clad in a robust armor of 1 to 6 millimeters, the veneer stands sentinel against the elements. Its thickness translates to unwavering strength, weathering storms and shielding interiors from the sun’s relentless glare. This muscular profile makes it the ideal champion for building exteriors, where resilience reigns supreme.

Aluminum Sheet: In contrast, sheet aluminum, armed with a nimble 0.5 to 3-millimeter physique, revels in its agility. It pirouettes across roofs, slithers sinuously through intricate ductwork, and even adorns interior walls with a graceful touch. This lighter profile grants it unmatched versatility, adapting to diverse applications without sacrificing structural integrity.

Formability

Aluminum Veneer: With its 1 to 6-millimeter thickness and forgiving grain structure, veneer bends to the will of the architect. CNC bending and thermoforming techniques unlock its potential, shaping it into intricate facades that mimic flowing fabrics or dramatic mountain ranges. This sculptural freedom empowers architects to push the boundaries of design, creating buildings that truly stand out.

Aluminum Sheet: While not as easily swayed, sheet aluminum’s 0.5 to 3-millimeter profile offers its own advantages. Its predictable formability allows for precise punching, bending, and folding, ideal for crafting robust components like roof panels, ventilation systems, and even sleek cabinet doors. This controlled bendability makes it a valuable asset for construction and industrial applications where accuracy and functionality are key.

Applications

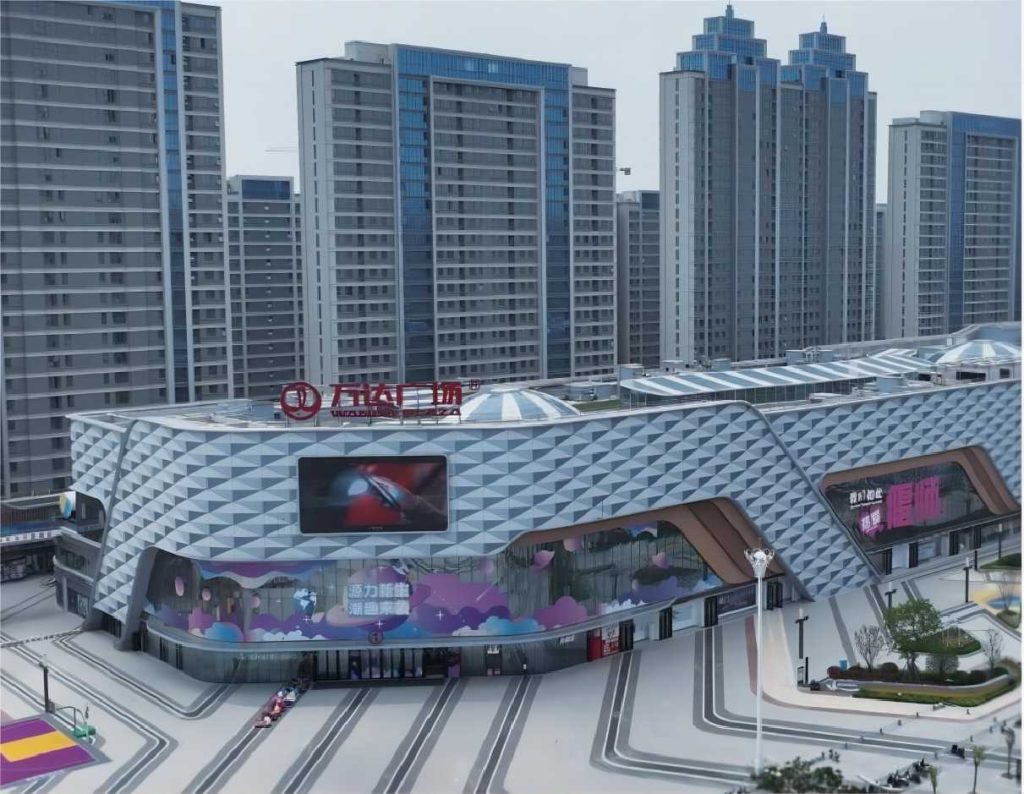

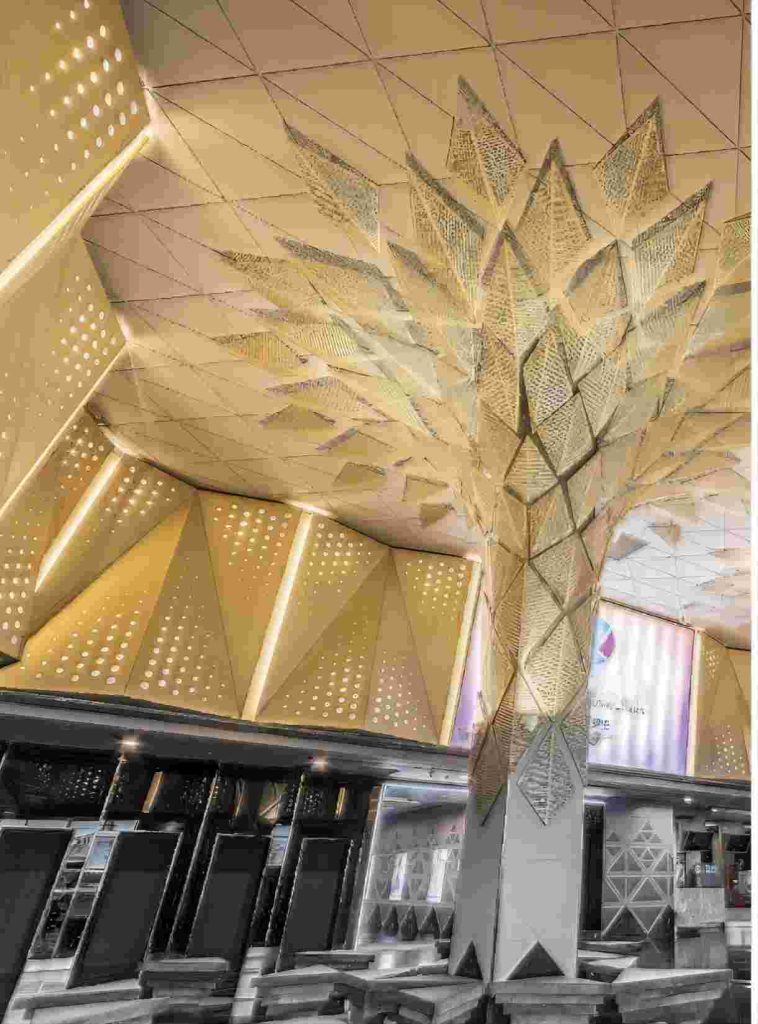

Aluminum Veneer: From the soaring curves of a modern museum to the intricate patterns on a traditional temple, aluminum veneer breathes life into architectural dreams. Its strength and beauty make it the ideal choice for exterior cladding, whether it’s a dazzling concert hall or a boutique hotel. Inside, it sculpts ceilings into soaring works of art and adds a touch of luxury to elevator lobbies and executive offices.

Aluminum Sheet: But aluminum sheet isn’t content to stay in the shadows. It’s the backbone of sturdy roofs, keeping homes and businesses safe from the elements. It’s the silent partner in efficient ventilation systems, ensuring the comfort of occupants. It even finds its way into kitchens and bathrooms, adding a touch of practicality with sleek countertops and backsplashes. This versatile material quietly touches every aspect of our built environment.

Cost

Aluminum Veneer: Like a handcrafted masterpiece, aluminum veneer commands a premium. Its intricate manufacturing process, involving precision shaping and bespoke finishes, demands a higher investment. But this premium translates into a lasting return: a stunning and durable exterior that elevates any building and stands the test of time.

Aluminum Sheet: While veneer struts its stuff on the catwalk of aesthetics, sheet aluminum cuts a more budget-friendly figure. Its simpler production process and standard finishes make it the go-to choice for projects where functionality takes center stage. So, if you’re looking for a reliable workhorse without breaking the bank, sheet aluminum is your trusty companion.

The key differences between aluminum veneer and aluminum sheet can be summarized as follows:

| Feature | Aluminum Veneer | Aluminum Sheet |

| Concept | Building material made from a single sheet of aluminum alloy | Basic material used in a variety of applications |

| Manufacturing process | Thermoforming | Rolling |

| Thickness | Typically 1-6 millimeters | Typically 0.5-3 millimeters |

| Formability | More formable | Less formable |

| Applications | Decorative applications | Functional applications |

| Cost | More expensive | Less expensive |

Conclusion

In the architectural realm, aluminum wears many hats. The opulent cloak of aluminum veneer, woven with intricate textures and vibrant hues, graces facades with an air of sophistication. The sturdy shield of aluminum sheet, unassuming yet unyielding, stands sentinel against the elements. Choosing between these two titans is not a mere matter of cost or aesthetics; it’s a dance of understanding their distinct strengths and weaknesses. Only by discerning their unique personalities can you unlock the full potential of aluminum, transforming it from a material into a canvas for your vision.