Aluminum plates are widely used in architectural landscape design, ranging from large building facades to small partitions of landscape walls. Aluminum plates may be used when the metal decoration is required. Today, this article will introduce the application design of aluminum plates in the landscape demonstration area.

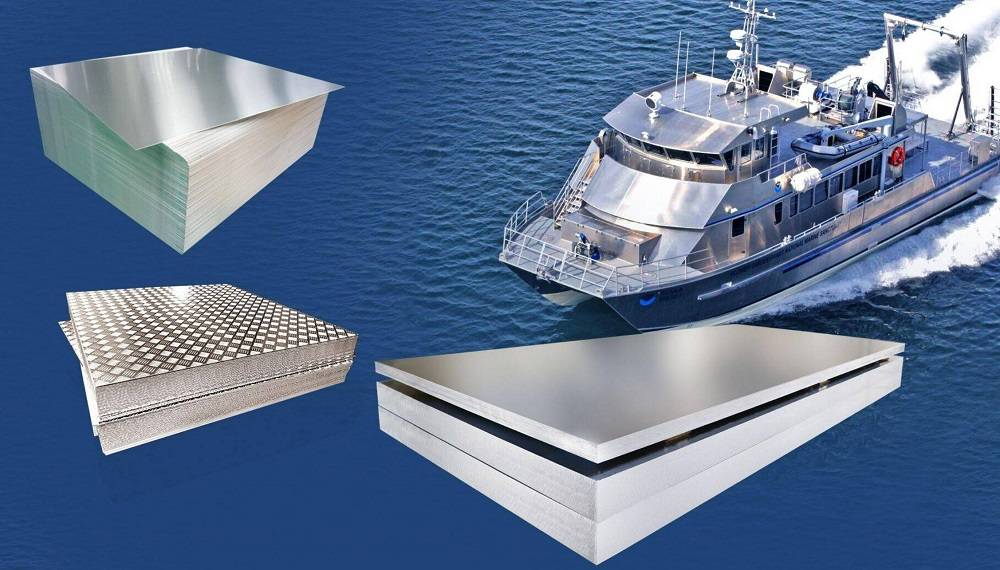

Types of aluminum plates

First of all, in terms of classification, aluminum plates used for architectural decoration are mainly divided into aluminum veneer and composite panels.

Aluminum veneer refers to a new building decoration material that uses an aluminum alloy sheet as the base material, is processed by customization, and then formed by numerical control bending technology, and processed by fluorocarbon or powder spraying technology. Perforated aluminum plates, imitation stone aluminum plates, wood grain transfer aluminum plates, mirror aluminum plates, etc. that are often said to belong to this type of aluminum plate.

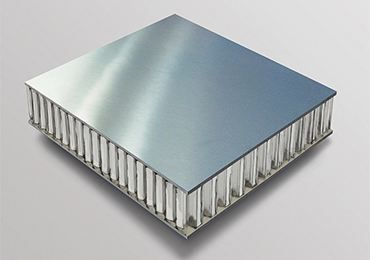

The aluminum composite plate is a general term, which mainly refers to the use of chemically treated coated aluminum plates (aluminum veneers) as surface materials through various complex processing methods, which are compounded on suitable base materials to form aluminum composite panels. According to the different composite substrate materials, aluminum composite plates have different material properties. The more common ones are aluminum-plastic plates, honeycomb aluminum plates, etc.

Application of perforated aluminum plates in the architectural landscape

Compared with other metal materials, the perforated aluminum plate has a smooth surface and has the advantages of high-temperature resistance, corrosion resistance, fire prevention, moisture resistance, shock resistance, light and stable structure, good building physical environment, wide sight line, and beautiful appearance. A new material that also serves as a decoration.

In terms of the building in the above picture material selection, ultra-clear glass, perforated aluminum plate, and U-shaped glass are selected for the facade. Among them, the perforated aluminum plate was designed parametrically. In the design of the hole size, considering the dual display personality of daylight and lighting, the specifications of 20mm, 15mm, and 10mm are selected for arrangement, presenting transparency to the hazy multi-layered visual effect.

Application of imitation stone aluminum plates in the architectural landscape

The appearance and texture of the imitation stone aluminum plate are very similar to stone, and the decorative effect is the same as stone. In terms of performance, the physical properties of the imitation stone aluminum veneer are better than stone, and the imitation stone aluminum veneer makes up for it by overcoming many defects of the stone itself. It has become an ideal substitute for stone by its appearance and physical properties.

The building in the above picture uses five iconic materials, stone-like texture aluminum plate, copper-like brushed aluminum plate, LOW-E white glass curtain wall, light gray aluminum plate, and dark gray aluminum plate, and the material range is reasonably divided according to different functional spaces.

Application of Imitation wood grain aluminum plates in the architectural landscape

The imitation wood grain aluminum plate is also called the wood grain transfer aluminum plate. It is a decorative material that uses high-grade aluminum alloy as the main material and presents the texture and color of wood on the aluminum plate through the transfer process.

It has the texture of wood, the characteristics of aluminum plate, and has many advantages. Such as effect simulation, green environmental protection, lightweight, fireproof, anti-corrosion, and moisture-proof, can process various geometric shapes, easy to care for, long service life, etc.

It has developed rapidly in recent years and has been widely used in aluminum profile curtain walls, doors and windows, and home furnishing, and has become one of the new growth points of the aluminum profile industry.

The building in the picture uses gray aluminum plates and imitation wood-grain aluminum plates with highly reflective ultra-clear glass, creating a collision between reality and reality. The roof of the aluminum-magnesium-manganese plates fluctuates and changes, and the corners are staggered and warped to form commanding heights. With the contrasting outline of the imitation wood-grain aluminum plates, the sense of line and continuity is sublimated.

Application of Mirror aluminum plate in the architectural landscape

Mirror aluminum plate refers to the aluminum plate that has been processed by various methods such as rolling and grinding to make the surface of the plate show a mirror effect. Generally, mirror aluminum sheets are made into coils or sheets by rolling.

It has excellent characteristics such as being lightweight, corrosion resistance, high-temperature resistance, not easy to rust, wide range of uses, and strong decorative effect. Due to the mirror reflection of the skin, it can connect the surrounding environment and has a strong visual effect. It is widely used in many fields and plays an important role.

For example, in the building in the picture above, the bottom box is designed as a black mirror aluminum plate, crawling and disappearing on the hillside. The metal skin reflects the whirling branches under the light and shadow, and the soft, light, and hazy image is displayed in front of the eyes.

In addition to the above four common types of aluminum plates, aluminum plates can also be processed into various geometric shapes such as plane, arc, and spherical surfaces by first processing and then painting, to meet the complex modeling requirements of buildings.

Related Products

Related Articles