Aluminum veneer panels are a rapidly growing trend in the construction industry, offering a unique blend of aesthetics, performance, and durability. These versatile panels can be used for a wide variety of applications, from building facades and interior walls to signage and furniture. This article will explore the key aspects of aluminum veneer panels, including their composition, types, properties, applications, and installation methods.

What are Aluminum Veneer Panels?

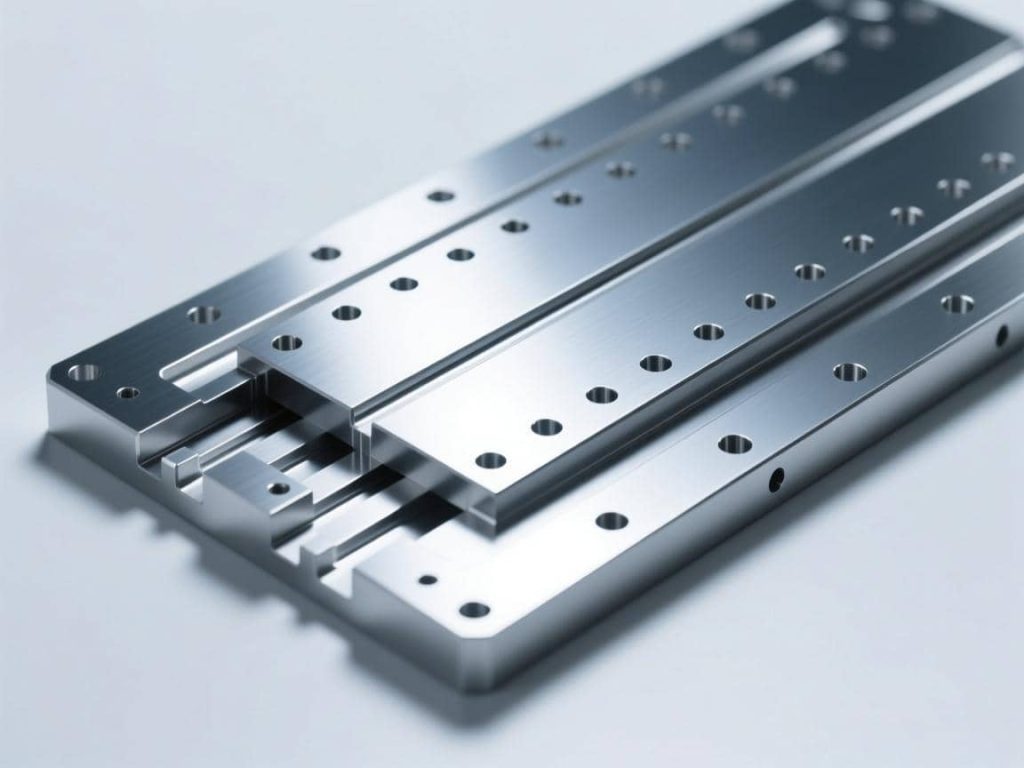

Aluminum veneer panels are thin sheets of aluminum that have been bonded to a core material, typically polyethylene or fire-retardant core. This composite structure provides panels with strength, rigidity, and excellent thermal and acoustic insulation properties. Unlike solid aluminum panels, which can be heavy and expensive, veneer panels offer a cost-effective alternative without compromising on quality or performance.

Types of Aluminum Veneer Panels

Aluminum veneer panels come in a variety of types, each with unique properties and applications. Here are some of the most common types:

- By Material

- Solid Aluminum Panels: These panels offer the highest strength and durability but are also the most expensive and heaviest.

- Aluminum Composite Panels (ACPs): These are the most common type of aluminum veneer panel. They consist of two thin aluminum sheets bonded to a low-density core, offering a good balance of strength, weight, and cost.

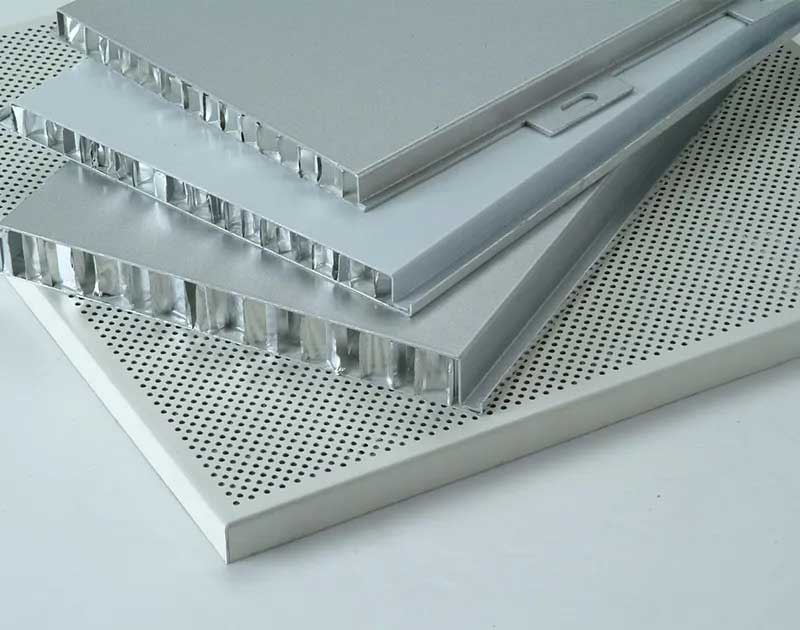

- Aluminum Honeycomb Panels: These panels have a honeycomb core made of aluminum foil, providing exceptional strength-to-weight ratio and fire resistance.

- Perforated Aluminum Panels: These panels have holes punched through them, allowing for ventilation, light diffusion, and unique design possibilities.

- By Finish

- Anodized Aluminum Panels: This process creates a protective oxide layer on the surface of the aluminum, enhancing its durability and corrosion resistance. Anodized panels offer a variety of colors and finishes, from natural metallic to vibrant hues.

- Powder Coated Aluminum Panels: This process involves applying a dry powder coating to the aluminum surface, which is then cured under heat. Powder coating provides a durable and scratch-resistant finish with a wider range of color options than anodizing.

- PVDF Coated Aluminum Panels: PVDF (polyvinylidene fluoride) coating is a high-performance finish that offers exceptional resistance to fading, weathering, and chemicals. These panels are ideal for exterior applications in harsh environments.

- Brushed Aluminum Panels: This finish creates a textured surface with a matte appearance. Brushed aluminum panels offer a sleek and modern look and help to hide minor scratches and imperfections.

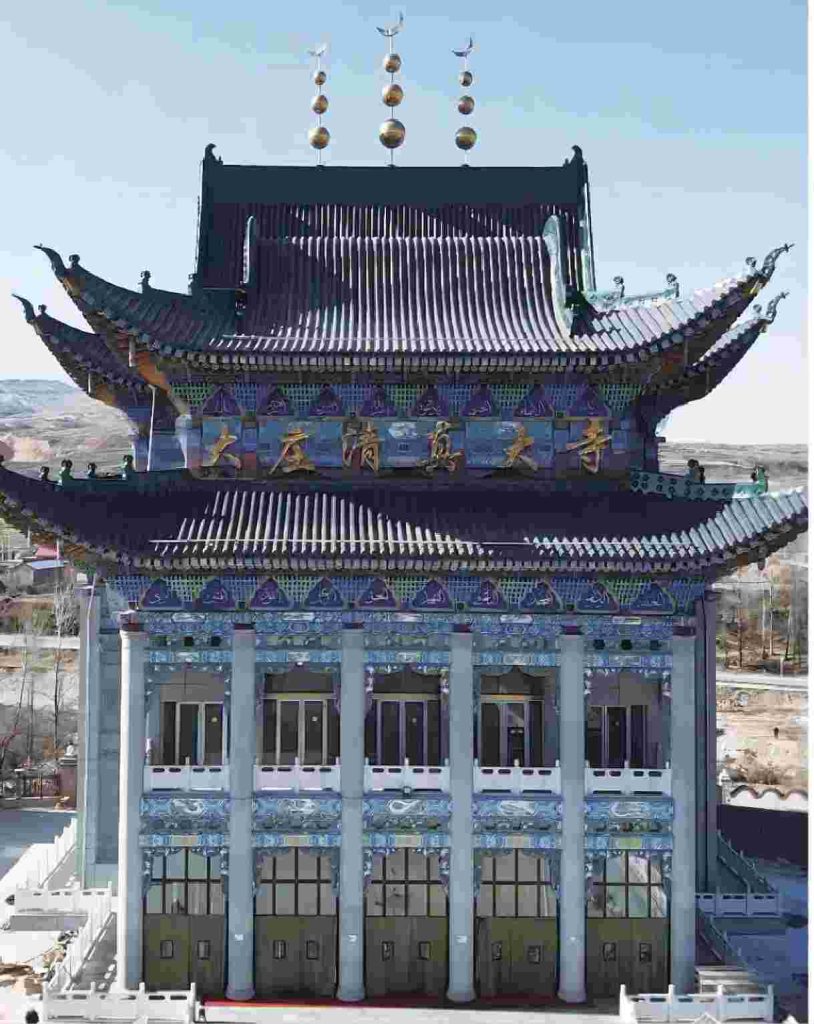

- Wood Grain Aluminum Panels: These panels are printed with a realistic wood grain pattern, offering a natural aesthetic without the maintenance required for real wood.

- By Size and Shape

- Aluminum veneer panels are available in various standard sizes, ranging from small panels for interior applications to large panels for building facades.

- Custom sizes and shapes are also available to meet specific design requirements.

Performance and Properties

Aluminum veneer panels offer several key performance and property benefits:

- Lightweight and Strong: The composite structure of aluminum veneer panels makes them significantly lighter than solid aluminum panels while maintaining excellent strength and rigidity.

- Durable and Weather-Resistant: Aluminum is naturally resistant to corrosion and rust, making veneer panels ideal for exterior applications. Additionally, various finishes, such as anodization and PVDF coating, further enhance their weather resistance.

- Fire-Retardant: Several types of aluminum veneer panels are fire-rated and can meet various building codes’ fire safety requirements.

- Low Maintenance: Aluminum veneer panels require minimal maintenance, making them a cost-effective choice over the long term. Regular cleaning with mild soap and water is sufficient to keep them looking their best.

- Recyclable: Aluminum is one of the most recyclable materials, making it an environmentally friendly choice.

Applications of Aluminum Veneer Panels

The versatility of aluminum veneer panels makes them suitable for a wide range of applications:

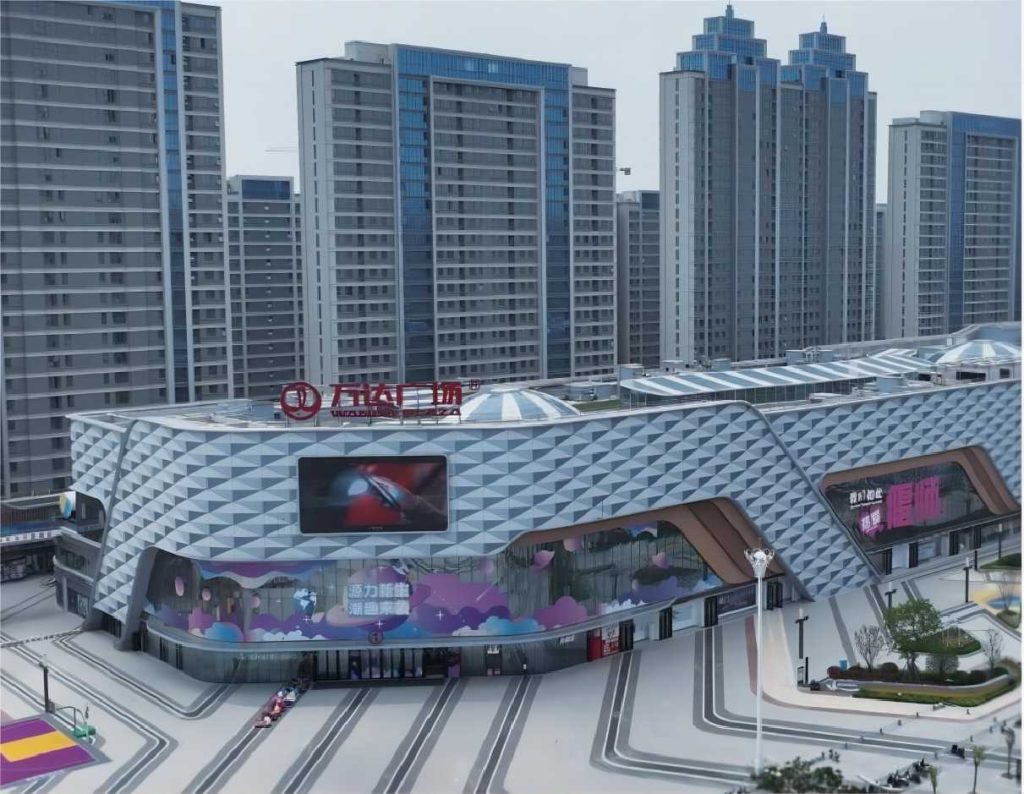

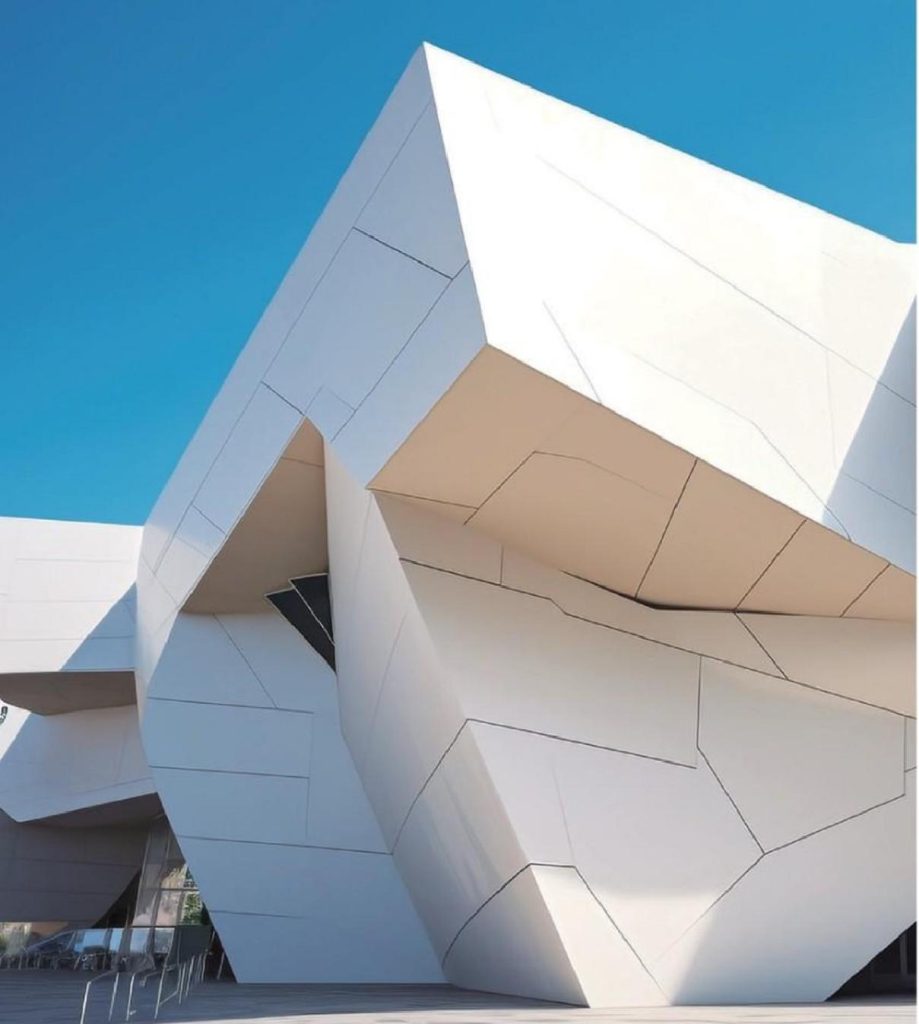

- Building Facades: Aluminum veneer panels are a popular choice for exterior building facades. They offer a modern and sophisticated look, enhance energy efficiency, and provide excellent weather protection.

- Interior Walls and Ceilings: Aluminum veneer panels can be used to create stunning interior walls and ceilings. They add a touch of elegance and sophistication to any space while being easy to clean and maintain.

- Column Wraps: Aluminum veneer panels can be used to wrap columns and architectural features, creating a visually appealing and seamless design.

- Signage and Displays: Aluminum veneer panels are ideal for creating durable and eye-catching signage and displays. Their customizable nature allows for unique and creative design possibilities.

- Furniture: Aluminum veneer panels can be used to create modern and stylish furniture pieces, such as tables, chairs, and cabinets.

- Decorative Elements: Aluminum veneer panels can be used to add a unique and decorative touch to any space. They can be used to create wall panels, sculptures, art installations, and other creative elements.

Installation of Aluminum Veneer Panels

The installation of aluminum veneer panels is a specialized process requiring trained professionals. The specific installation method will depend on the type of panel, project requirements, and building structure. However, some general steps are involved in the installation process:

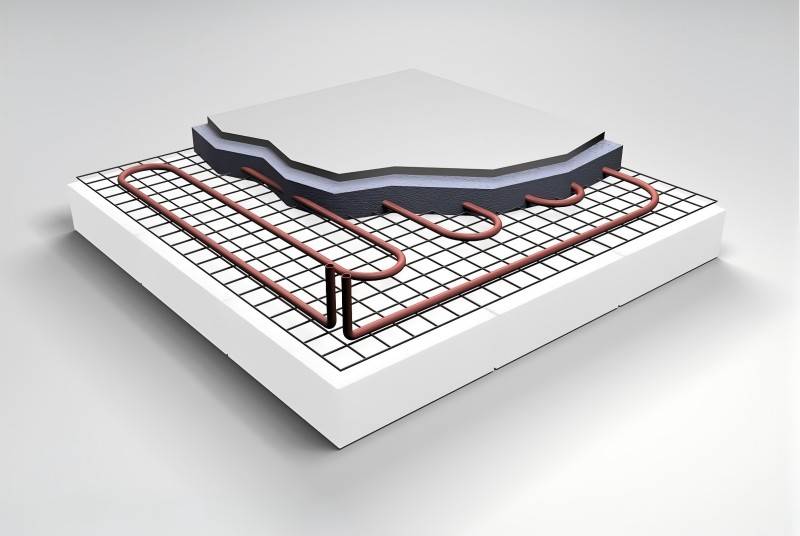

- Preparation and Substructure: The installation surface must be prepared to ensure a smooth and secure installation. This may involve leveling the surface, installing insulation, and attaching the necessary substructure elements.

- Panel Installation Methods: Aluminum veneer panels can be installed using various methods, including hang-on systems, reveal systems, and cassette systems. The chosen method depends on the panel type, design requirements, and building codes.

- Sealants and Adhesives: Applying high-quality sealants and adhesives is crucial for ensuring long-term performance and preventing water infiltration.

Maintenance and Cleaning

Aluminum veneer panels require minimal maintenance to maintain their beauty and functionality. Regular cleaning with mild soap and water is sufficient to remove dirt and debris. Avoid using harsh chemicals or abrasive cleaners, as they can damage the surface of the panels. It is also recommended to perform periodic inspections to identify any potential damage and address it promptly.

Environmental Considerations

Aluminum is a sustainable and recyclable material, making aluminum veneer panels an environmentally friendly choice. Here are some key points to consider:

- Sustainability of Aluminum: Aluminum is one of the most abundant metals on Earth and is highly recyclable. Over 70% of all aluminum ever produced is still in use today.

- Recycling and Reuse: Aluminum veneer panels can be easily recycled at the end of their life, minimizing their environmental impact.

- Environmental Impact of Manufacturing and Installation: While the manufacturing process of aluminum has an environmental impact, advancements in technology have significantly reduced emissions and resource consumption. Additionally, the long lifespan and low maintenance requirements of aluminum veneer panels contribute to their overall sustainability.

Conclusion

Aluminum veneer panels offer a modern and versatile solution for various applications in architecture, design, and construction. Their combination of lightweight strength, durability, aesthetic appeal, and sustainable qualities makes them a compelling choice for architects, designers, and homeowners alike. As technology and innovation continue to evolve, we can expect even more exciting possibilities for the use of aluminum veneer panels in shaping the future of building and design.