Introduction

The decorative materials of the architectural metal curtain walls are the main products of today’s architectural curtain walls, including aluminum veneer, aluminum plate, and aluminum honeycomb panel. Among these three materials, the most commonly used are aluminum veneer and aluminum composite panel. But what is the difference between an aluminum composite panel and an aluminum honeycomb panel?

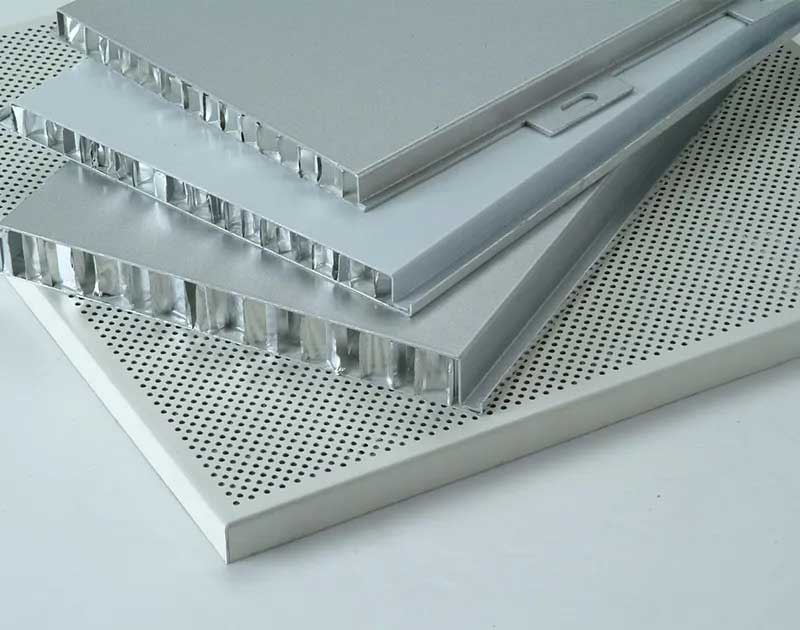

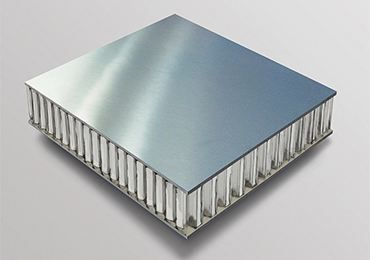

What is Aluminum Honeycomb Panel?

The aluminum honeycomb panel is also called plywood. A honeycomb panel is composed of two aluminum plates, which are firmly adhered to a layer of aluminum honeycomb core material, and are formed by hot pressing. Aluminum honeycomb panel is a new type of green decorative material that saves resources, protects the ecological environment, and is cost-effective in developed countries over the years. Core, using special composite process cold pressing and hot pressing technology.

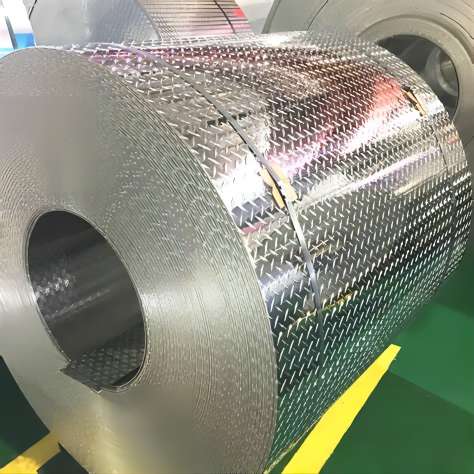

What is Aluminum Composite Panel?

The aluminum composite panel is the abbreviation of aluminum-plastic composite panel. It takes polyethylene plastic as the core material, and chemically treated coated aluminum plate (also known as aluminum foil, aluminum coil, or aluminum strip) as the surface material. After certain processing (continuous hot pressing) composite) a composite material. Aluminum composite panel has good performance waterproof, fireproof, insect-proof, acid and alkali resistance, friction resistance, stain resistance, easy cleaning, sound insulation, and heat insulation.

Aluminum Honeycomb vs Aluminum Composite: Applications

aluminum honeycomb panel

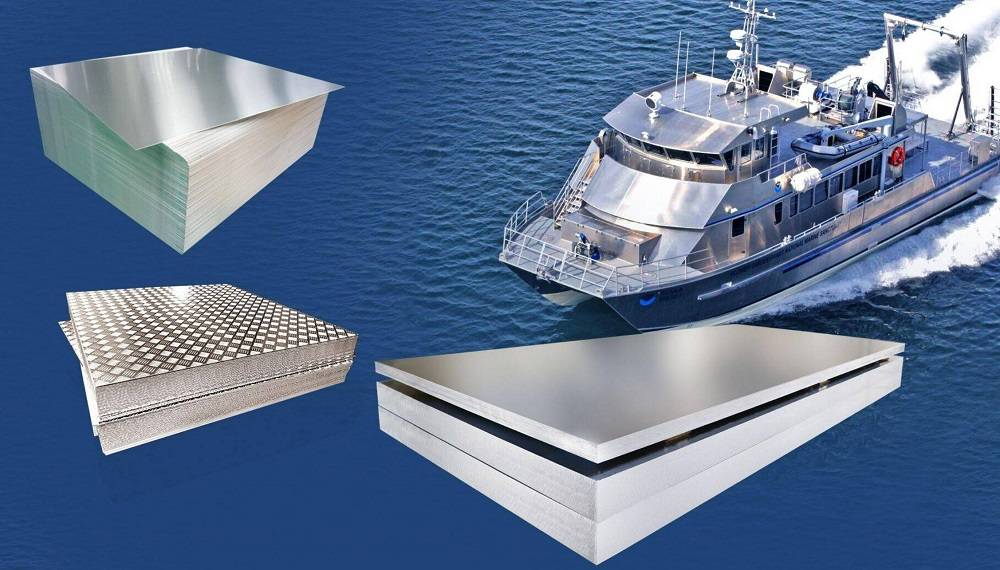

The aluminum honeycomb panels are generally used in the following fields: building curtain wall siding, interior decoration, billboards, shipbuilding, aviation manufacturing, indoor partitions, buses, high-speed rail, subway and rail transit vehicles, etc. In addition, the requirements are relatively strict for the modern home furnishing industry, the use of aluminum honeycomb panels as furniture processing materials has been a better choice these years. Necessary environmental protection procedures, in addition, the panels of aluminum honeycomb panels can be diversified, such as wood materials, natural stone, ceramics, etc. can be made into honeycomb panels.

aluminum composite panel

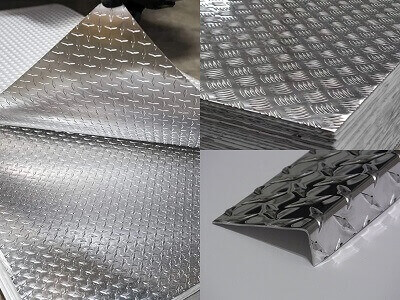

According to the scope of use and purpose, it can be classified into indoor aluminum composite panels and outdoor aluminum composite panels. Indoor aluminum panels are also called interior wall panels. The surface of aluminum panels is generally roller coated with polyester resin coating, and the outdoor is also called an exterior wall. In panels or curtain wall panels, the surface of the aluminum panel is coated with polyvinylidene fluoride resin, which is often referred to as fluorocarbon coating, abbreviated as PVDF. It has strong weather resistance and chemical corrosion resistance and has a certain ability to resist the sun, rain, or bad weather.

Aluminum Honeycomb vs Aluminum Composite: Characteristics

Aluminum Honeycomb Panel

An aluminum honeycomb panel is a composite material formed by bonding aluminum honeycomb core material and surface material. In general, an aluminum honeycomb panel has the following basic characteristics:

- Lightweight, high specific strength, especially high flexural rigidity, the flexural rigidity of aluminum honeycomb panels of the same quality is about 5 times that of aluminum alloys.

- It has extremely high surface flatness and high-temperature stability, which is easy to form and not easy to deform. Aluminum honeycomb panels can not only be made into flat panels but also into hyperbolic and single-curved panels, which are easy to disassemble and assemble after being made into vehicle parts.

- Excellent corrosion resistance, insulation, and environmental adaptability can adapt to various harsh operating environments of railway EMUs and passenger cars. In addition, according to needs, this type of board can be treated with surface painting or surface paste fireproof board to achieve good decoration and fire resistance.

- The unique resilience can absorb vibration energy and has good sound insulation and noise reduction effect.

- After encountering a fire, the smoke density complies with the high-level international railway fire protection standards, and has good self-extinguishing properties; the exothermic value is low, which can form a refractory layer, which can reduce the released smoke and toxic gases, and has excellent environmental performance.

- The excellent molding and manufacturing process can meet the requirements of complex shapes and high stability of the internal parts of railway vehicles.