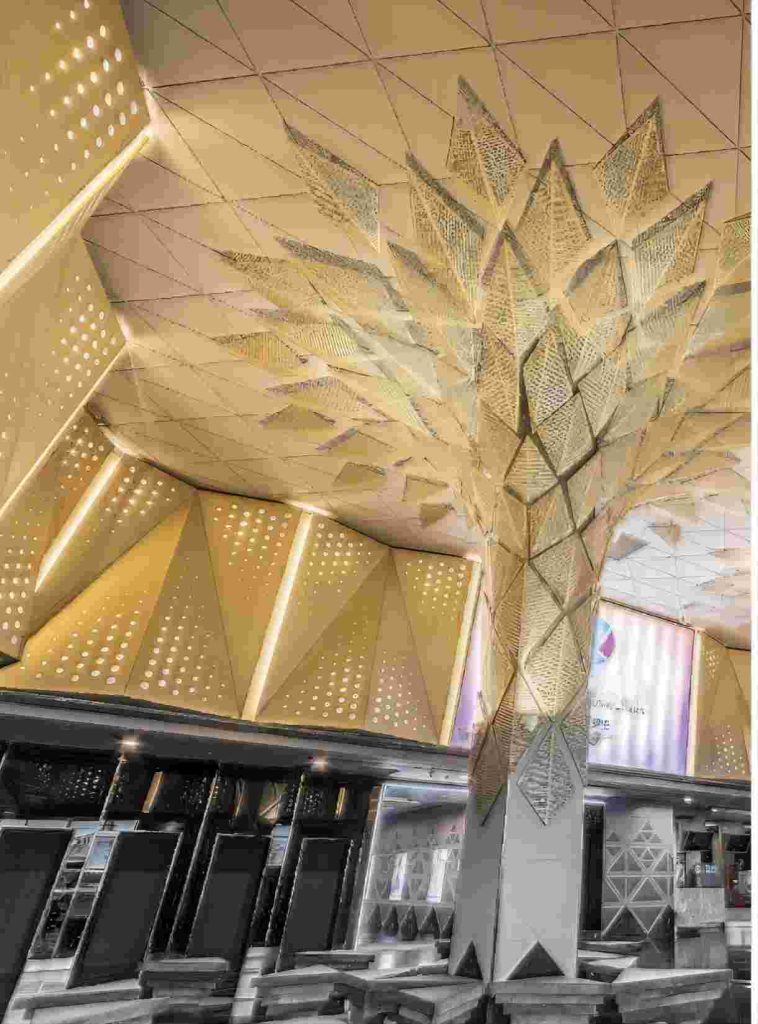

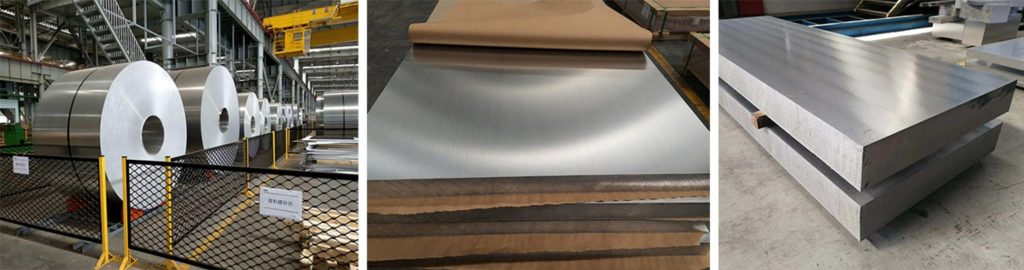

Aluminum plates are a versatile material widely used in various industries, from construction to automotive and aerospace. Their lightweight nature, excellent corrosion resistance, and strength-to-weight ratio make them an ideal choice for numerous applications. However, to fully harness these benefits, aluminum plates must undergo different processing techniques that enhance their functionality. In this article, we will explore the common methods used to process aluminum plates, followed by answers to frequently asked questions about aluminum plate processing.

What are the Main Methods for Processing Aluminum Plates?

Aluminum plate processing methods are crucial to transforming raw aluminum into a usable form suitable for industrial applications. The most common methods include:

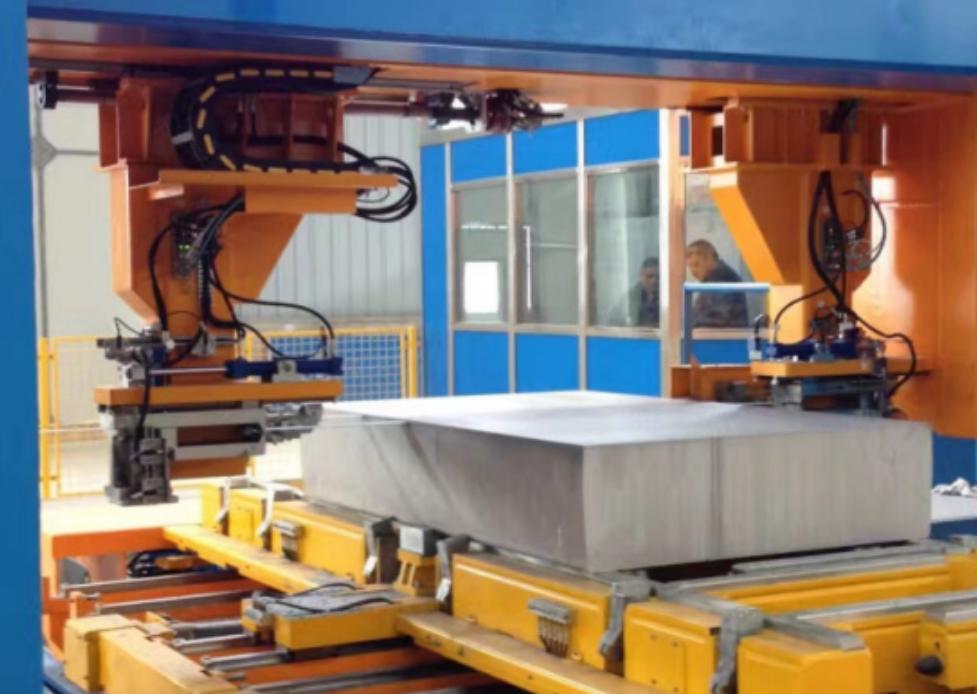

- Rolling: The aluminum ingot is drawn into plates of different thicknesses at high temperature or room temperature through a rolling mill. This is the most common method where aluminum slabs are rolled to reduce thickness. It can be classified into hot and cold rolling processes. Hot rolling is done at high temperatures, making the aluminum more malleable and can obtain larger plates, while cold rolling enhances surface finish and strength.

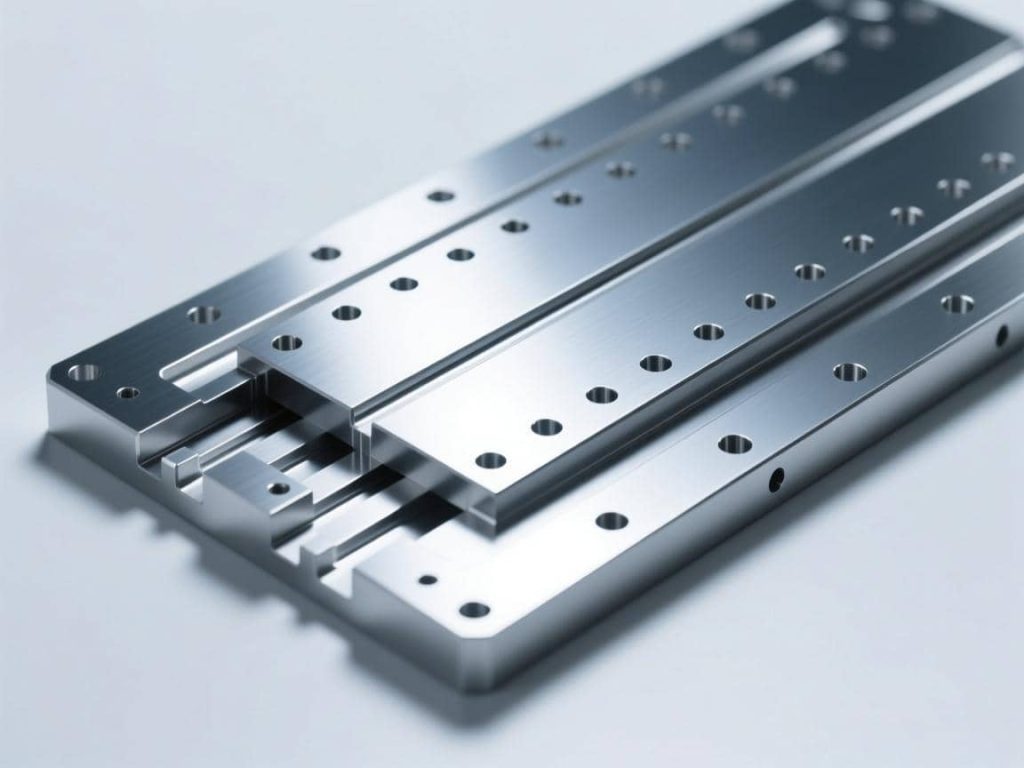

- Cutting: Various cutting methods are used depending on the required precision and shape. Laser cutting provides high accuracy, waterjet cutting uses high-pressure water for non-thermal cutting, and mechanical cutting is preferred for large-scale projects.

- Bending: This method allows aluminum plates to be shaped into specific curves or angles. Common bending methods include press brake bending, which uses a mechanical press, and roll bending, which involves rolling the aluminum around a die to create a bend.

- Drawing: In this process, aluminum plates are pulled through a die to achieve a thinner or specific profile. This method is widely used in creating aluminum parts for industries like automotive and aerospace.

- Anodizing: During anodizing, the aluminum plate is immersed in an acid electrolyte bath, and an electric current is applied to form an oxide layer on its surface. This electrochemical process enhances the aluminum’s corrosion resistance and can also improve its appearance.

- Surface treatment: Including polishing, sandblasting, electroplating, spraying, etc., which are used to improve the appearance and surface properties of aluminum plates.

- Welding: Aluminum plates can be connected by a variety of welding methods, such as TIG welding, MIG welding, laser welding, etc., which are used to manufacture complex aluminum structures.

These processing methods can be used alone or in combination to meet the design and performance requirements of different products.

5 FAQs About Aluminum Plate Processing

Q1: What are the two stages in the rolling process of aluminum plates?

The rolling process of aluminum plates is usually divided into two main stages: rough rolling and finishing rolling.

Rough rolling stage

The rough rolling stage mainly involves the initial plastic deformation of aluminum ingots or billets through the rolling mill to reduce their thickness and approach the size of the final product. At this stage, the rolling speed is relatively fast and the rolling force is large to ensure that the material can pass through the rolling mill smoothly. The aluminum plate after rough rolling usually has a thicker thickness and a larger tolerance range.

Finishing rolling stage

The finishing rolling stage follows the rough rolling, with the purpose of further reducing the thickness of the aluminum plate and improving the surface finish and dimensional accuracy of the plate. At this stage, the rolling speed will be reduced and the rolling force will be adjusted to ensure the uniform deformation of the material and the quality requirements of the final product. The aluminum plate after finishing rolling has a thinner thickness, higher surface quality and a smaller tolerance range.

The rolling process of these two stages is crucial to ensure the final performance and application of the aluminum plate. Through the combination of rough rolling and finishing rolling, the microstructure and macroscopic size of the aluminum plate can be effectively controlled to meet the needs of different industrial applications.

Q2: How are Aluminum Plates Bent or Formed?

Aluminum plates are bent or formed through several techniques, depending on the desired shape, thickness, and precision. Here’s how aluminum plates are typically bent or formed:

1. Press Brake Bending

This involves using a press brake machine, which applies force to bend the aluminum plate along a straight line. The plate is clamped between a punch and a die, and the punch presses down to create the bend.

Applications: Ideal for creating sharp, precise bends and angles. Commonly used in manufacturing and fabrication for creating components like brackets, enclosures, and panels.

2. Roll Bending

Roll bending involves passing the aluminum plate through a set of rollers that gradually bend the plate into curves or arcs. The rollers can be adjusted to achieve different radii of curvature.

Applications: Suitable for creating large, smooth curves or cylindrical shapes. Often used in structural components and architectural applications.

3. Air Bending

In air bending, the aluminum plate is bent using a punch that does not touch the bottom die. Instead, the plate is bent by the punch pressing into the air gap above the die.

Applications: Provides flexibility in bend angles and allows for variations in material thickness and bend radius. Common in situations where precise control over the bend angle is required.

4. Bottoming

Bottoming is a type of bending where the punch fully engages with the die, allowing the aluminum plate to be bent to a precise angle with minimal springback (the tendency of the material to return to its original shape).

Applications: Used when exact bend angles and minimal deformation are critical. Ideal for high-precision applications.

5. Stretch Forming

Stretch forming involves stretching the aluminum plate over a mold or die while simultaneously applying heat. The plate is stretched and bent to conform to the mold’s shape.

Applications: Suitable for creating complex, curved shapes with smooth surfaces. Often used in aerospace and automotive industries for parts with aerodynamic profiles.

6. Hammering or Forging

In hammering or forging, the aluminum plate is manually or mechanically hammered or pressed to shape it. This technique can involve both hot and cold processes.

Applications: Used for creating custom shapes or artistic forms where traditional bending methods may not be practical. Often employed in metalworking and artistic applications.

Each method has its advantages depending on the required shape, precision, and volume of production. Choosing the right technique involves considering factors such as the thickness of the aluminum plate, the complexity of the bend, and the intended use of the finished product.

Q3: What is the Difference Between Aluminum Plate Drawing and Bending?

Drawing and bending are distinct processes, each serving different purposes in shaping aluminum plates.

Drawing is a process where an aluminum plate is pulled through a die to create a thinner or specific profile, often used for precision parts in automotive or aerospace industries.

Bending, on the other hand, involves applying force to change the shape of the aluminum plate into an angle or curve. It’s commonly used in construction and architecture to create structural components.

The primary difference lies in the resulting shape and the complexity of the form, with drawing often yielding more intricate profiles than bending.

Q4: How does the anodizing process of aluminum plates improve their corrosion resistance?

Anodizing enhances the corrosion resistance of aluminum plates by forming a protective oxide layer on the surface.

In the process, the aluminum plate is immersed in an acid electrolyte bath, and an electric current is applied, causing oxygen ions to bond with the aluminum surface.

This oxide layer is harder and more durable than the raw aluminum, providing significant protection against environmental factors such as moisture, chemicals, and salt, making it an ideal choice for outdoor and marine applications.

Q5: How do you prevent warping during aluminum plate processing?

Warping, or distortion, can occur due to uneven heating, cooling, or stress during the aluminum plate manufacturing process. Here are some strategies to prevent warping:

1. Proper Heating and Cooling

- Uniform Heating: Ensure that the aluminum plate is evenly heated during processes like hot rolling or annealing. Uneven heating can lead to differential expansion and contraction, causing warping.

- Controlled Cooling: Cool the aluminum plates slowly and uniformly after processing. Rapid or uneven cooling can induce residual stresses and warping. Using controlled cooling techniques or cooling jigs can help manage temperature gradients.

2. Stress Relief

- Annealing: After processes that induce significant stress (like rolling or bending), anneal the aluminum plate to relieve internal stresses. Annealing involves heating the plate to a specific temperature and then allowing it to cool slowly.

- Stress-Relief Techniques: Apply stress-relief techniques such as vibration stress relieving or heat treatment to minimize residual stresses that could cause warping.

3. Proper Tooling and Fixturing

- Correct Tooling: Use well-maintained and properly calibrated tools and machines for cutting, bending, and forming. Dull or misaligned tools can create uneven forces, leading to warping.

- Effective Fixturing: Ensure that the aluminum plate is securely and evenly clamped or supported during processing. Proper fixturing helps prevent movement and distortion.

4. Precision in Processing

- Controlled Processing Parameters: Maintain precise control over processing parameters such as temperature, pressure, and feed rates. Inconsistent parameters can lead to uneven processing and warping.

- Monitoring and Adjustments: Continuously monitor the processing conditions and make necessary adjustments to maintain consistency and prevent warping.

5. Material Quality

- High-Quality Raw Materials: Use high-quality aluminum alloys and ensure that the raw material is free from defects. Impurities or inconsistencies in the material can contribute to warping during processing.

- Proper Material Handling: Handle aluminum plates with care to avoid introducing any pre-existing stresses or deformities before processing.

6. Design Considerations

In cases where warping is a concern, consider design adjustments that minimize stress concentrations and ensure uniform distribution of forces. For example, avoid sharp corners and transitions in designs that require bending or forming.

7. Post-Processing Treatments

After processing, use straightening techniques to correct any warping that may have occurred. Techniques such as mechanical straightening or heat treatment can help restore the plate to its desired shape.

By implementing these strategies, you can significantly reduce the risk of warping during aluminum plate processing and achieve high-quality, dimensionally accurate products.

Aluminum plate processing is a complex field with various methods tailored to meet specific industrial needs. From rolling and cutting to bending, drawing, and anodizing, each process serves a unique purpose in enhancing the performance and usability of aluminum plates. Understanding these techniques is essential for selecting the right method for a given application. By addressing common questions about aluminum plate processing, we hope this article provides valuable insight into the best practices and considerations when working with aluminum plates.