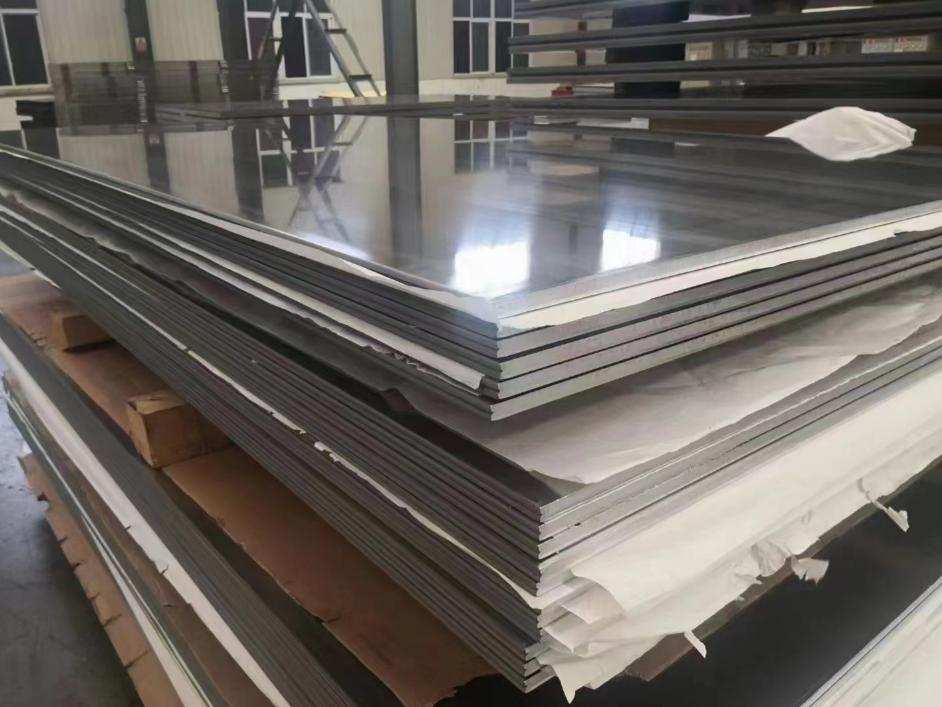

Recent developments in contemporary construction have made aluminum sheets one of the most multifunctional resources in regards to the design, function, and eco-friendliness of the construction. There are several external elements to buildings; aluminum is versatile. It’s used for facade panels, ceilings, secondary decorative claddings, and roofing systems, and the type of aluminum alloy and thickness used will determine the architectural impressions and how long the building will last.

To every construction professional and project executive, determination of the correct alloy type and its measurement(s) is one of the most fundamental project specifications, with implications for overall estimated budget for the project, its structural function, and successful completion of the project.

Thus, for one of the leading suppliers of aluminum sheets, CHAL Aluminium, we provide a practical guide in order to make the most correct selection of aluminum sheets.

Selecting the Alloy for Architectural Use

The alloy choice dictates the material’s fundamental properties—its strength, formability, and most importantly for architecture, its suitability for various surface finishes.

Common Aluminum Alloy Series for Architecture

Different aluminum alloy series provide different balances of strength, formability, and corrosion resistance. Below is a summary of commonly used aluminum alloy series in architectural applications:

| Alloy Series | Key Features | Typical Architectural Applications | Manufacturer’s View (CHAL) |

| 1xxx Series (Pure Aluminum) | Excellent corrosion resistance, high reflectivity, easy formability, but low strength. | Decorative panels, interior ceiling cladding, curtain wall backing sheets. | Best for projects prioritizing appearance and corrosion resistance over structural strength. CHAL recommends anodized or coated finishes for long-term protection. |

| 3xxx Series (Al-Mn Alloys, e.g., 3003) | Good corrosion resistance and formability, moderate strength, suitable for bending and forming. | Roofing sheets, facade panels, perforated ceiling panels. | A cost-effective and versatile option. CHAL often supplies 3003 with PVDF or polyester coating for weather durability. |

| 5xxx Series (Al-Mg Alloys, e.g., 5052, 5005, 5083) | High strength, excellent corrosion resistance (especially in marine or humid environments), good weldability. | Exterior wall cladding, curtain wall panels, marine and coastal architecture. | A top choice for structural and outdoor projects. CHAL typically recommends 5005 for anodized finishes due to its color consistency. |

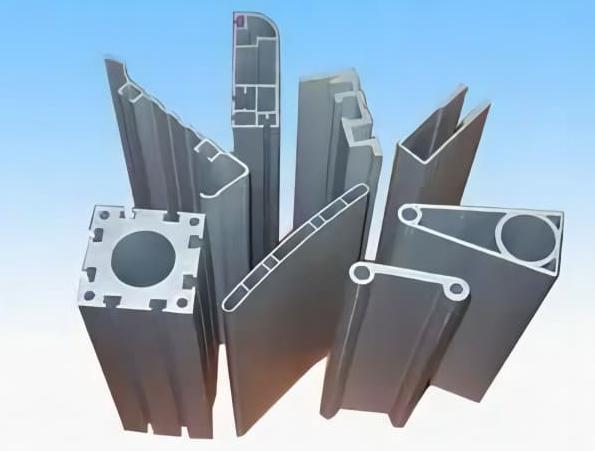

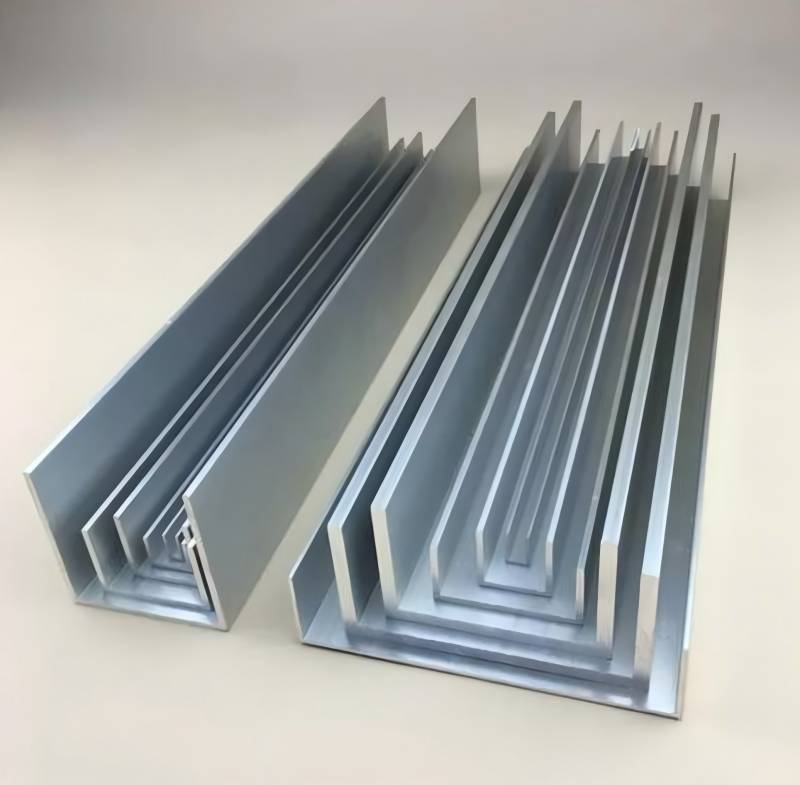

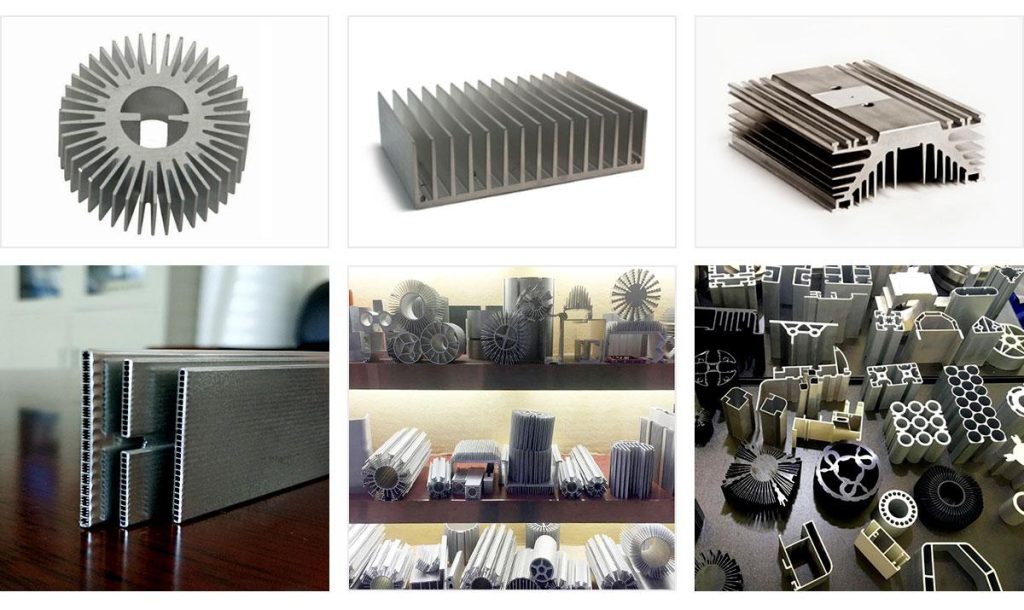

| 6xxx Series (Al-Mg-Si Alloys, e.g., 6061, 6063) | High strength, good corrosion resistance, excellent surface finish after anodizing or powder coating. | Window frames, door frames, curtain wall extrusions, architectural profiles. | CHAL frequently supplies 6063-T5 extrusions for facade and framing systems due to its excellent strength-to-weight ratio and smooth surface quality. |

| 7xxx Series (Al-Zn-Mg Alloys) | Very high strength, moderate corrosion resistance, more expensive, less common in architecture. | Structural reinforcement components, special architectural elements requiring rigidity. | Used only in niche applications. CHAL advises clients to balance performance with fabrication difficulty and cost before selecting this series. |

CHAL Aluminium provides everything your company needs in customized architectural aluminium sheets, including alloys 3003, 5052, 5083, and 6061 in all tempers (H14, H24, T6), best suited to meet varying needs for fabrication and performance.

How Surface Finish Impacts Alloy Selection

Surface treatment not only affects the appearance of the building, but also directly affects the durability and maintenance requirements of the material. Different surface treatment processes have different requirements for the substrate:

| Surface Finish Type | Key Benefits | Compatible Alloy Series | Typical Use Cases | Manufacturer’s Insight (CHAL) |

| Mill Finish (Uncoated) | Natural metallic appearance, low cost, suitable for indoor or temporary applications. | 1xxx, 3xxx, 5xxx | Ceiling panels, interior decorative elements, signage. | CHAL suggests this only for controlled environments since uncoated aluminum can oxidize and lose luster over time. |

| Anodized Finish | Enhances corrosion resistance and surface hardness; provides a uniform metallic appearance with color options. | 5xxx, 6xxx (especially 5005 and 6063) | Curtain walls, facade cladding, window and door frames. | CHAL recommends 5005 for consistent anodizing color across large panels and 6063 for precision extrusions. |

| PVDF Coating (Polyvinylidene Fluoride) | Superior UV and weather resistance, excellent color retention, ideal for outdoor architectural projects. | 3xxx, 5xxx | Exterior wall panels, roofing, modern building facades. | A CHAL specialty finish for high-end projects requiring 20+ years of color stability and gloss retention. |

| Powder Coating | Wide range of colors, durable surface, environmentally friendly (no VOC emissions). | 5xxx, 6xxx | Frames, railing systems, custom decorative facades. | CHAL’s powder coating lines support custom RAL colors and special textures to meet architectural aesthetics. |

| Brushed / Mirror Finish | Enhanced visual effect, often used for modern or luxury designs; requires controlled alloy composition for consistency. | 1xxx, 5xxx | Elevator panels, lobbies, high-end interiors. | CHAL ensures tight surface roughness control through precision rolling and surface treatment before brushing. |

Let’s take a look at how an architectural building is designed and how selecting suitable alloys and surface finishes impacts how a building performs and ages over many decades after it has been constructed. For CHAL Aluminium, an integrated service provider, custom architectural alloys and surface finishes allows the optimisation of every panel, profile or extrusion for composition and finish.

Determining Thickness: Balancing Function and Economy

Choosing the right aluminum sheet thickness involves finding the balance between mechanical strength, weight, and cost. Too thin, and panels may deform or vibrate; too thick, and material costs rise unnecessarily.

Key Factors Driving Thickness Selection

1. Wind Load and Structural Requirements

Wind pressure is one of the most significant external forces acting on building facades and roofs. The greater the wind load, the thicker and stiffer the aluminum panel needs to be to resist deformation and vibration.

For instance:

- High-rise buildings or coastal structures exposed to strong winds require 3.0–4.0 mm panels for safety and long-term stability.

- Low-rise commercial buildings or sheltered locations can typically use 2.0–2.5 mm panels.

Our engineering team provides finite element analysis (FEA) and structural simulation to ensure each panel thickness meets wind resistance and deflection criteria, preventing failures under extreme weather conditions.

2. Panel Size and Support System

The width and span of aluminum panels have a direct impact on required thickness. Larger panels or those with fewer fixing points are more prone to bending and oil-canning.

Typical reference guidelines:

| Panel Span (mm) | Recommended Thickness (mm) | Notes |

| ≤ 600 | 1.5–2.0 | Small decorative panels or soffits |

| 600–1200 | 2.0–2.5 | Standard cladding panels |

| 1200–1800 | 3.0–4.0 | Large facade elements or ceiling systems |

CHAL assists clients during the design-for-manufacturing (DFM) phase, adjusting panel layouts or adding stiffeners to minimize unnecessary thickness and material waste.

3. Building Function and Location

The purpose and exposure of the building also shape thickness decisions:

- Public infrastructure (airports, stations): thicker panels (≥3 mm) ensure long service life under heavy use.

- Residential or commercial interiors: thinner panels (1.5–2.5 mm) are sufficient since loads are minimal.

- Outdoor installations in industrial or marine zones may demand thicker sheets with 5xxx series alloys to resist corrosion and fatigue.

CHAL’s experience:

We often combine alloy optimization with coating technology, such as using 5052-H32 aluminum with PVDF coating for seaside projects where salt exposure is high.

4. Forming and Bending Requirements

Complex architectural designs—such as curved facades, folded edges, or 3D profiles—require aluminum sheets with excellent formability.

- Thicker panels offer rigidity but reduce flexibility.

- Thinner panels are easier to bend and shape, but may lose structural strength.

CHAL recommends:

- 1.5–2.0 mm for deep bending or tight radii,

- 2.5–3.0 mm for moderate folds, and

- ≥3.0 mm for flat or slightly curved panels requiring stiffness.

Our CNC bending and laser cutting facilities ensure precise forming even in thicker materials without surface cracking.

5. Cost and Weight Considerations

Finally, aluminum thickness directly affects both material cost and overall building weight.

Increasing thickness from 2.0 mm to 3.0 mm adds roughly 50% more material cost and weight.

For high-rise projects, optimizing thickness can reduce structural load and installation costs significantly.

We help clients find the “sweet spot” between performance and economy, using advanced simulation tools and yield optimization during sheet cutting to minimize waste and cost.

Minimum Thickness and Stiffness Standards

Industry guidelines such as ASTM B209 and GB/T 3880 define the minimum thickness and tolerance for architectural aluminum sheets.

To ensure both safety and economy, most engineers perform finite element analysis (FEA) or load testing to verify panel stiffness under specific conditions.

At CHAL, we work closely with clients to provide thickness optimization recommendations, reducing unnecessary weight without compromising performance. The following table outlines the recommended thickness ranges for common architectural applications:

| Application Scenario | Recommended Thickness Range | Key Considerations |

| Interior Ceiling/Partition | 0.6 – 1.2 mm | 0.6 mm is often sufficient for residential ceilings; commercial projects may require 0.8 mm or above for better sag resistance. |

| Standard Curtain Wall | 2.0 – 3.0 mm | 2.5 mm is the mainstream choice for most commercial and high-end residential facades, offering a balance of stiffness and cost. |

| High-Rise Curtain Wall | 2.5 – 4.0 mm | The final thickness must be determined by detailed wind pressure calculations based on building height and location. |

| Perforated/Embossed Sheets | 2.5 – 4.0 mm | Increased thickness is often necessary to compensate for the material strength reduction caused by perforations or patterns. |

| Architectural Roofing | 2.5 – 4.0 mm | Must account for ponding water, snow loads, and occasional foot traffic for maintenance. |

Beyond the base sheet thickness, the use of stiffeners is a critical strategy to enhance panel rigidity. For large panel sizes or in high-wind zones, adding aluminum alloy stiffeners to the back of the panel allows for the use of a relatively thinner gauge sheet, achieving structural performance while optimizing material cost and weight.

Partnering with the Right Manufacturer

CHAL Aluminium supports architects and contractors through every stage—from material selection and design consultation to custom cutting, forming, and coating.

CHAL Services including:

- Full Alloy Range: 1000–7000 series aluminum sheets and coils.

- Comprehensive Surface Treatment: Anodizing, PVDF coating, powder coating, mirror, and brushed finishes.

- Precision Fabrication: Advanced CNC machining, laser cutting, and bending capabilities for tailor-made components.

- Sustainability: CHAL offers recyclable aluminum materials aligned with green building initiatives.

- Global Supply Chain: Fast delivery and reliable logistics for large architectural projects worldwide.

When selecting architectural aluminum panels, the most expensive isn’t necessarily the most suitable, nor is the thinnest the most economical. A successful choice comes from a comprehensive consideration of material properties, building requirements, and environmental conditions.

Only when the alloy composition and thickness specifications of each aluminum panel are perfectly matched to its intended purpose can a building truly achieve a harmonious unity of form and function, aesthetics and performance.

Connect with CHAL today to discuss your next project’s specific aluminum sheet requirements.