To address climate change and enhance energy security, the world is transitioning towards sustainable energy, and renewable energy has become the top priority in infrastructure construction. With the continuous advancement of technologies such as solar photovoltaic, wind energy and energy storage systems, the structural components that support these innovative technologies must also develop accordingly. The market demand for materials that combine the advantages of light weight, high strength, durability, corrosion resistance and easy installation is increasing day by day.

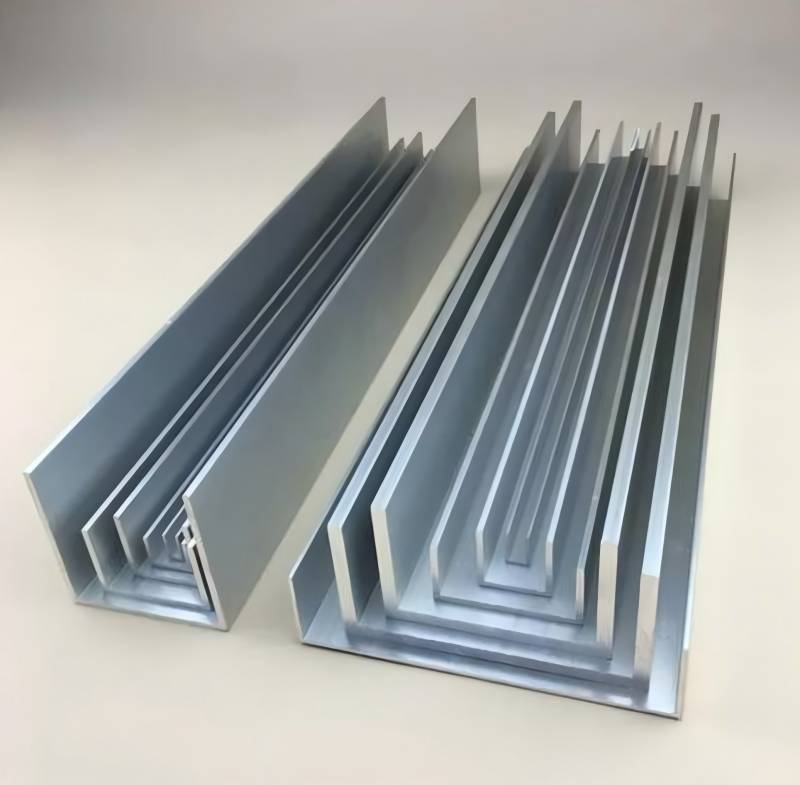

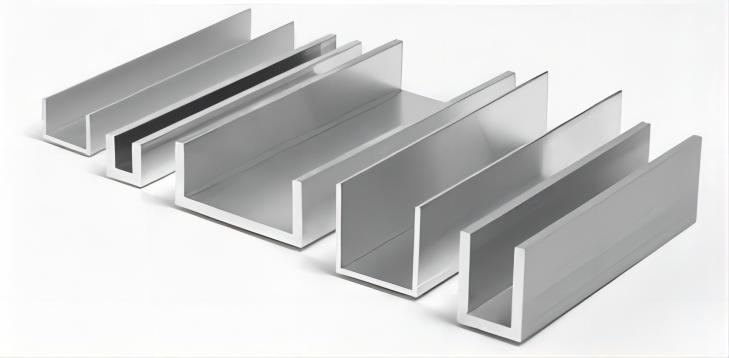

This article explores the crucial role that aluminum extruded profiles – especially aluminum U channels and wider aluminum U profiles – play in meeting these demanding requirements. These versatile profiles have become important materials for enhancing the efficiency of renewable energy infrastructure and extending its service life.

The Material and Structural Advantages of Aluminum U Profiles

Aluminum alloys, especially 6000 series alloys, make them ideal materials for outdoor structural applications. Its strength-to-weight ratio enables it to produce structures that are stronger and lighter than steel, thereby reducing the load on the foundation and simplifying transportation and logistics.

The advantages of aluminum U Channel

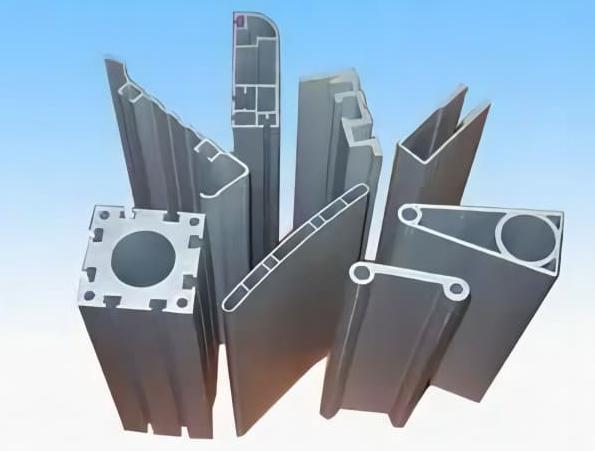

The unique “U” shaped design of this profile endows it with outstanding mechanical properties. This geometric form has been precisely designed to effectively resist bending moment and torque loads, which is crucial for installation in strong wind and snowy environments. In addition, the extrusion molding process can produce profiles with high precision, uniform specifications and easy connection, thereby meeting the modular assembly requirements of large-scale energy projects.

Main materials and structural advantages include:

- Corrosion resistance: aluminum naturally forms a layer of passivated oxide, which effectively prevents environmental erosion – this is essential for solar power plants in coastal or high humidity areas. Surface treatment processes such as anodizing can further enhance its corrosion resistance.

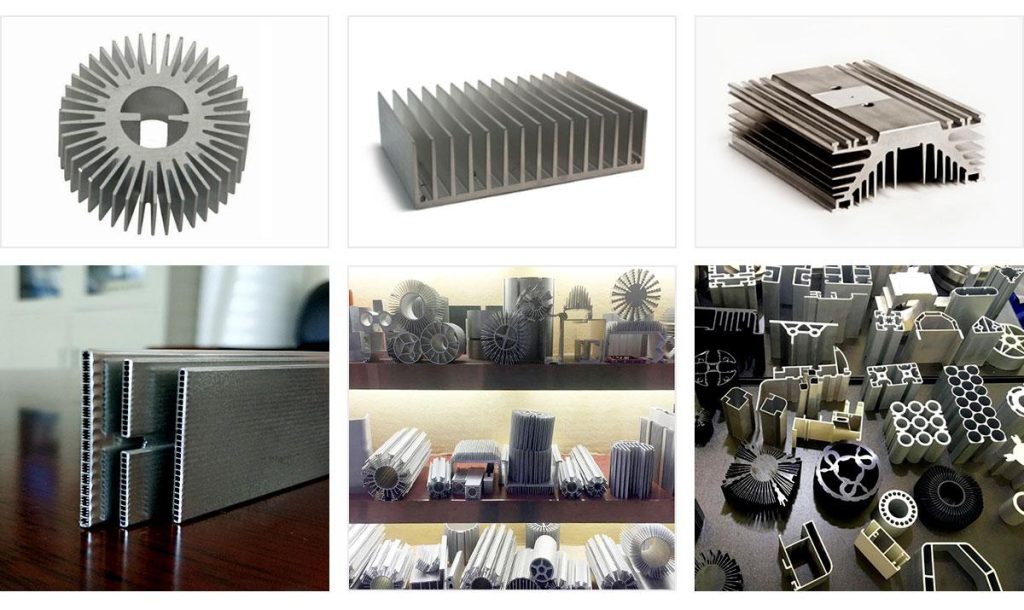

- Thermal management: The excellent thermal conductivity of aluminum is crucial in energy systems, especially in the heat dissipation of components such as battery casings and electronic device casings, thereby enhancing the overall performance and service life of the system.

- Recyclability: Aluminum can be recycled infinitely without losing quality, which is in perfect alignment with the sustainable development goals of the renewable energy industry.

Application Case Studies in Renewable Energy Structures

The multi-functionality of aluminum U channel is best demonstrated in the three pillars of the new energy structure:

1. Photovoltaic (PV) Installation System

In solar power plants and roof installations, aluminum U-shaped channel are the core components for bracket installation.

Function: It acts as the main track or support bracket for fixing PV modules to the ground or roof.

Impact: Its lightweight feature simplifies the installation process on sensitive surfaces such as rooftops, while its high mechanical strength ensures that the array can withstand extreme weather events. The extruded slot can integrate functions such as cable management, achieving a neat and protected wiring system. The tolerance of high-precision aluminum U channel is crucial for maintaining the correct tilt Angle, thereby maximizing energy capture efficiency.

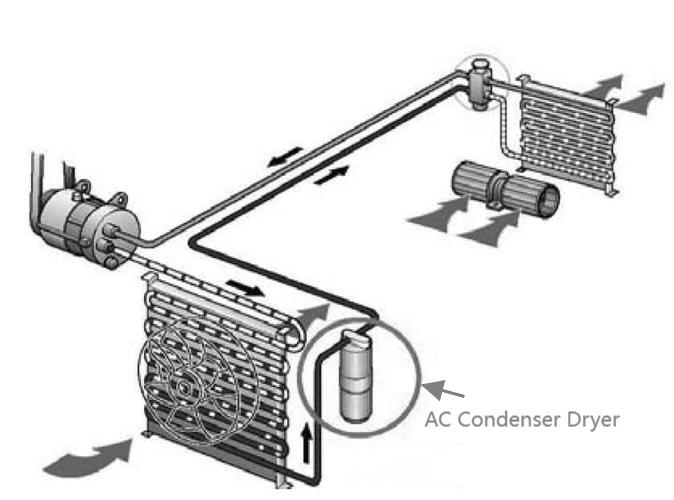

2. Wind Energy Infrastructure

Function: They are utilized in the construction of nacelle internal frames, access platforms, and cable management trays.

Impact: The use of lightweight aluminum components, including U-shaped profiles, in the cabin can reduce the overall mass of the top of the tower, thereby reducing the burden on the bearing components and lowering manufacturing costs. The use of these components in corrosion-resistant platforms is particularly important for offshore wind power projects exposed to harsh Marine environments.

3. Energy Storage Systems (ESS)

As battery energy storage becomes a core element of grid balance, aluminum U-shaped slots play a key role in the design of modular battery packs.

Function: They are used as structural frames for individual battery modules or battery racks within larger containers.

Impact: The thermal conductivity of this material is utilized for effective heat dissipation, which is crucial for the safety and performance of the battery. The structural rigidity of aluminum U-shaped slots is crucial for maintaining the integrity of battery packs, resisting vibrations and external shocks.

Future Trends and Sustainability

The future development of aluminum U profiles in this field will focus on continuous innovation:

- High-strength alloys: The industry is constantly seeking new types of aluminum alloys with a higher strength-to-weight ratio to further reduce material usage while maintaining or enhancing load-bearing capacity.

- Integrated functions: Future designs will enable aluminum U-shaped channel to have multiple functions – integrating cable management, fluid cooling, and quick connection functions into a single complex extruded profile.

- Sustainability and circular economy: Aluminum is often referred to as the “green metal” due to its extremely high recyclability and minimal loss of material performance. The use of aluminum U profiles is in perfect alignment with the sustainable development goals of the new energy sector, which helps to reduce the overall embodied carbon emissions of renewable energy installations.

Summary

Energy transition not only requires innovative power generation technologies, but also a stable, efficient and sustainable structural framework. Aluminum U-shaped channels and aluminum U-profiles are indispensable materials in modern renewable energy applications. They integrate lightweight design, high strength and excellent corrosion resistance, ensuring that solar, wind and energy storage systems have long lifespan and cost-effectiveness, and become a true pillar for the world towards a cleaner energy future.