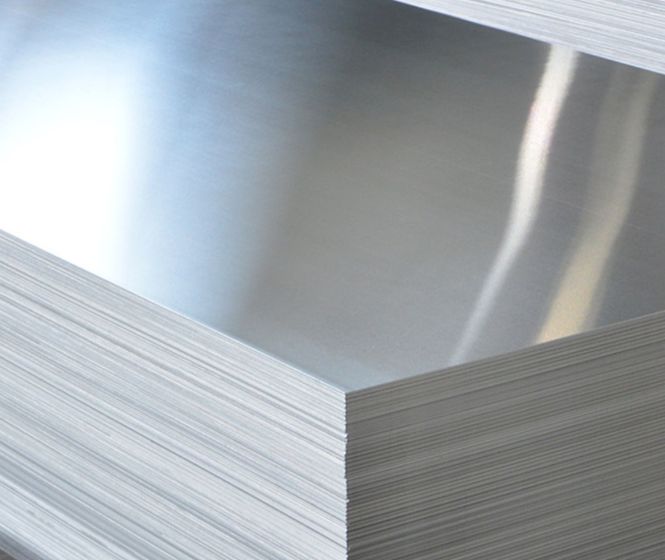

It might be difficult to distinguish among different series of aluminum sheets, such as the 1xxx, 3xxx, and 5xxx series. In this article, we’ll provide you with some basic information about these common aluminum sheet series. We’ll explain their characteristics and applications, so you can better understand the differences between them.

Aluminum sheets grouping standard

Based on the national standard for aluminum sheet designation, there are 8 main groups that aluminum sheets can be classified into. Additionally, according to the national standard “Denotation Method of Deformed Aluminum and Aluminum Alloy Grades (GB/T 16474-2011),” four-character grades are used for naming aluminum sheets. The first, third, and fourth characters are Arabic numerals, while the second character is an English capital letter.

The second letter in the grade’s name indicates how the initial pure aluminum or aluminum alloy was changed, while the last two digits identify different aluminum alloys within the same group and also indicate the purity of the aluminum.

Aluminum Sheets – the difference in features and applications

In this part, you will know the features and application of aluminum sheets from 1xxx series aluminum sheets to 8xxx series aluminum sheets.

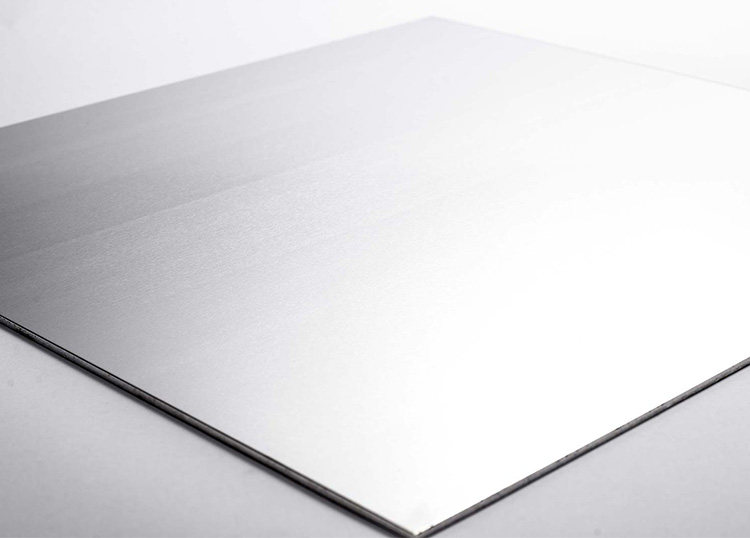

- 1××× series aluminum sheets

For industrial pure aluminum, the 1xxx series aluminum sheet is a brand series with the highest aluminum content. The amount of aluminum is at least 99.0%. It possesses high elongation, tensile strength, plasticity, and resistance to corrosion. The manufacturing method is relatively easy, the manufacturing technology is reasonably developed, and the pricing has a significant advantage. However, its strength is minimal, and it deforms easily when compressed.

This aluminum sheet is mainly used for signs, billboards, wall decorations, kitchen utensils, chemical equipment, electronic devices, and other products that do not require high strength.It is a series that is frequently employed in traditional industries.

At present, 1100, 1050, and 1060 series aluminum sheets are widely used in the building decoration industry.

- 2××× series aluminum sheets

The 2xxx series of aluminum sheets are made from an aluminum-copper alloy (Al-Cu), with copper as the primary alloying element. Copper content in this alloy typically ranges between 3-5%. These sheets have a high level of hardness and good cutting performance, as well as some heat resistance. However, they have poor corrosion resistance.

The primary applications for 2xxx series aluminum sheets are in industries and products that require high strength and high-temperature resistance, such as aircraft structures, missile components, spacecraft parts, and ship bodies.

- 3××× series aluminum sheets

The 3xxx series of aluminum sheets are made from an aluminum-manganese alloy (Al-Mn), which is also known as anti-rust aluminum sheets. Manganese is the primary alloying element in this alloy, with a content ranging between 1.0-1.5%. These sheets have higher strength than the 1xxx series of aluminum sheets, and they also have good formability, weldability, and corrosion resistance.

The 3xxx series of aluminum sheets are commonly used in industries that require strong anti-corrosion and anti-rust standards, such as building decoration, electronic production, and automotive manufacturing. In China, this series of aluminum sheets is widely used in various industrial applications.

Currently, 3003 aluminum sheets, 3004 aluminum sheets, and other series of aluminum sheets are commonly used in the building decoration industry.

- 4××× series aluminum sheets

The 4xxx series of aluminum sheets are made from an aluminum-silicon alloy (Al-Si), with silicon as the primary alloying element. The silicon content in this alloy typically ranges between 4.5-6.0%. These sheets have a moderate thermal expansion coefficient, good wear resistance, strong corrosion resistance, a low melting point, and high strength.

The 4xxx series of aluminum sheets are primarily used in welding materials.

- 5××× series aluminum sheets

The 5xxx series of aluminum sheets are made from an aluminum-magnesium alloy (Al-Mg), with magnesium as the primary alloying element. These sheets have excellent processing and forming properties, as well as corrosion resistance and weldability. They are widely used in various industries due to their low density and lighter weight compared to other series of aluminum sheets. The 5xxx series of aluminum sheets are commonly used in ship structures, aircraft fuel tanks, automobile fuel tanks, and other applications.

Currently, 5052 aluminum sheets and other series of aluminum sheets are widely used in the building decoration industry. In practical applications, 3-series aluminum sheets with strong hardness are generally used in aluminum veneer fluorocarbon curtain walls.

- 6××× series aluminum sheets

The 6xxx series of aluminum sheets are made from an aluminum-magnesium-silicon alloy (Al-Mg-Si), with magnesium and silicon as the primary alloying elements. These sheets have medium strength, good corrosion resistance, good weldability, and excellent oxidation resistance. They are mainly used in industries and products that require high levels of corrosion resistance and oxidation resistance.

- 7××× series aluminum sheets

The 7xxx series of aluminum sheets are made from an aluminum-zinc alloy (Al-Zn-Mg-(Cu)), with zinc as the primary alloying element. These sheets belong to the superhard aluminum alloy category, and they have excellent mechanical properties, wear resistance, and fatigue resistance. However, their corrosion resistance is poor, and they require aluminum cladding or other protective treatments to improve their corrosion resistance.

The 7xxx series of aluminum sheets are mainly used in aerospace equipment materials, but they are also widely used in various machinery, molds, and other processing and manufacturing fields.

- 8××× series aluminum sheets

8××× series aluminum sheets belong to other series of aluminum sheets, with other alloys as the main alloying elements, most of which are used as aluminum foil, which can be used in bottle caps, radiators, etc., and belongs to the less commonly used series.

Related Products

Related Articles: