Aluminum sheets are a versatile material that is used in a wide variety of applications. Two of the most common aluminum alloys are 5052 and 6061. These alloys have different properties, so it is important to choose the right one for your specific application.

What are Aluminum Sheets?

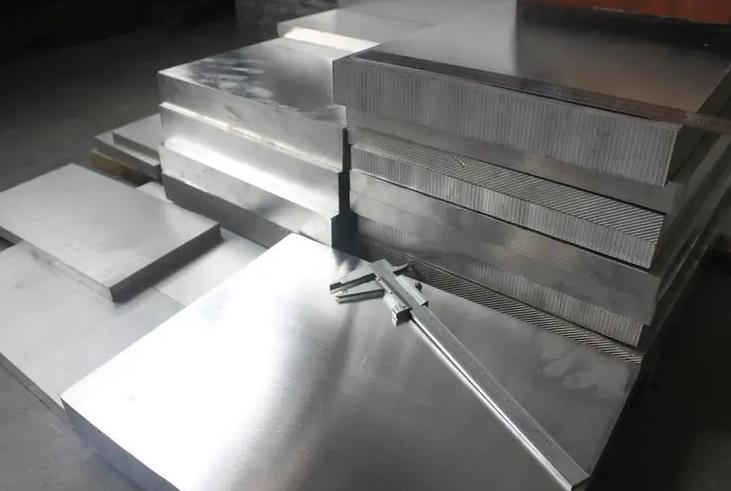

Aluminum sheets are thin, flat piece of aluminum that is used in a variety of applications. They are typically made by rolling aluminum ingots into a sheet. Aluminum sheets are available in a variety of thicknesses, widths, and lengths.

What are the 5052 and 6061 Aluminum Sheets?

The 5052 and 6061 aluminum sheets are both non-heat-treatable alloys. This means that their properties cannot be changed by heat treatment. However, they can be strengthened by cold working.

The 5052 aluminum sheet is a general-purpose alloy that is known for its corrosion resistance. It is also relatively ductile, meaning that it can be bent and stretched without breaking.

The 6061 aluminum sheet is a high-strength alloy that is known for its machinability. It is also relatively corrosion resistant.

Properties of 5052 and 6061 Aluminum Sheets

Mechanical Properties

The mechanical properties of 5052 and 6061 aluminum sheets are shown in the table below.

| Property | 5052 | 6061 |

| Tensile strength (MPa) | 220 | 276 |

| Yield strength (MPa) | 193 | 241 |

| Elongation (%) | 25 | 12 |

As you can see, 6061 aluminum sheet is stronger than 5052 aluminum sheet. However, 5052 aluminum sheet is more ductile than 6061 aluminum sheet. This means that 5052 aluminum sheet can be bent and stretched more without breaking.

Physical Properties

The physical properties of 5052 and 6061 aluminum sheets are shown in the table below.

| Property | 5052 | 6061 |

| Density (g/cm³) | 2.7 | 2.7 |

| Specific heat (J/kg·K) | 920 | 920 |

| Thermal conductivity (W/m·K) | 138 | 167 |

As you can see, 6061 aluminum sheet has a higher thermal conductivity than 5052 aluminum sheet. This means that 6061 aluminum sheet can dissipate heat more efficiently.

Chemical Properties

The chemical properties of 5052 and 6061 aluminum sheets are shown in the table below.

| Property | 5052 | 6061 |

| Corrosion resistance | Good | Good |

| Weldability | Good | Good |

| Machinability | Good | Excellent |

As you can see, both 5052 and 6061 aluminum sheets are corrosion resistant. However, 5052 aluminum sheet is slightly more corrosion resistant than 6061 aluminum sheet.

Why Are They Commonly Used?

5052 aluminum sheet is commonly used for the following applications:

- Marine applications:5052 aluminum sheet is commonly used for marine applications because of its corrosion resistance. It is used for boat hulls, docks, and other marine structures. 5052 aluminum sheet is also used for marine hardware, such as screws and bolts.

- Architectural applications: 052 aluminum sheet is commonly used for architectural applications because of its corrosion resistance and its ability to be bent and shaped. It is used for window frames, siding, and roofing. 5052 aluminum sheet is also used for architectural hardware, such as handrails and balustrades.

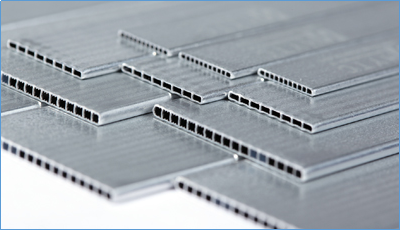

- Electrical applications: 5052 aluminum sheet is commonly used for electrical applications because of its conductivity. It is used for busbars, heat sinks, and other electrical components. 5052 aluminum sheet is also used for electrical enclosures, such as junction boxes and switchgear.

- Transportation applications: 5052 aluminum sheet is commonly used for transportation applications because of its strength and its corrosion resistance. It is used for truck beds, trailers, and other transportation equipment. 5052 aluminum sheet is also used for automotive components, such as wheels and suspension components.

6061 aluminum sheet is commonly used for the following applications:

- Structural applications:6061 aluminum sheet is commonly used for structural applications because of its strength. It is used for bridges, buildings, and other structures. 6061 aluminum sheet is also used for automotive components, such as chassis and suspension components.

- Automotive applications: 6061 aluminum sheet is commonly used for automotive applications because of its strength and its machinability. It is used for wheels, suspension components, and other automotive parts. 6061 aluminum sheet is also used for automotive body panels.

- Aerospace applications: 6061 aluminum sheet is commonly used for aerospace applications because of its strength and its light weight. It is used for aircraft structures, such as fuselages and wings. 6061 aluminum sheet is also used for spacecraft components, such as rocket bodies and satellites.

- Machinery applications: 6061 aluminum sheet is commonly used for machinery applications because of its strength and its machinability. It is used for machine tools, dies, and other machinery parts. 6061 aluminum sheet is also used for machinery housings and enclosures.

Conclusion

The best alloy for you will depend on your specific application. If you need an alloy that is corrosion-resistant, then 5052 aluminum sheet is a good choice. If you need an alloy that is strong, then 6061 aluminum sheet is a good choice. You should also consider the other factors listed in the article, such as weldability and machinability.