Computer-to-plate (CTP) is a printing technology that is revolutionizing the production of aluminum substrates. CTP uses a computer to create a printing plate directly from a digital file, which eliminates the need for film. This can save time and money, and it also makes it possible to produce aluminum substrates with higher quality and more complex designs.

What are CTP and Aluminum Substrates?

Computer-to-plate (CTP) is a printing technology that uses a computer to create a printing plate directly from a digital file. This eliminates the need for film, which can save time and money.

In traditional printing, the image is first created on film, which is then used to create a printing plate. This process can be time-consuming and expensive, and it also introduces the possibility of errors. CTP eliminates the need for film, which can save time and money.

Here are the different types of CTP technology:

- Laser CTP: This is the most common type of CTP technology. It uses a laser to create the printing plate.

- Inkjet CTP: This type of CTP technology uses inkjet technology to create the printing plate.

- Electron beam CTP: This type of CTP technology uses an electron beam to create the printing plate.

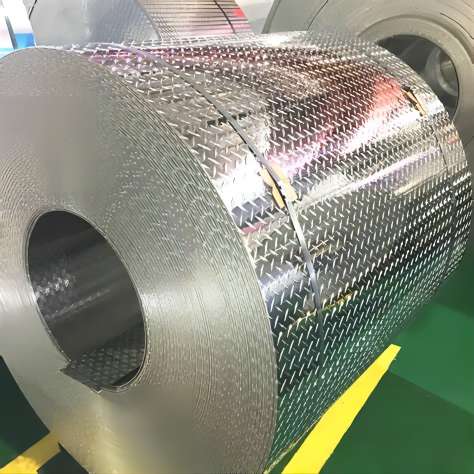

Aluminum substrate is a metal sheet or plate made of aluminum. There are many different types of aluminum substrate, each with its own unique properties and applications. Some of the most common types of aluminum substrate include:

- Cast aluminum: This is the most common type of aluminum substrate. It is made by melting aluminum and pouring it into a mold. Cast aluminum is strong and durable, and it can be used in a wide variety of applications.

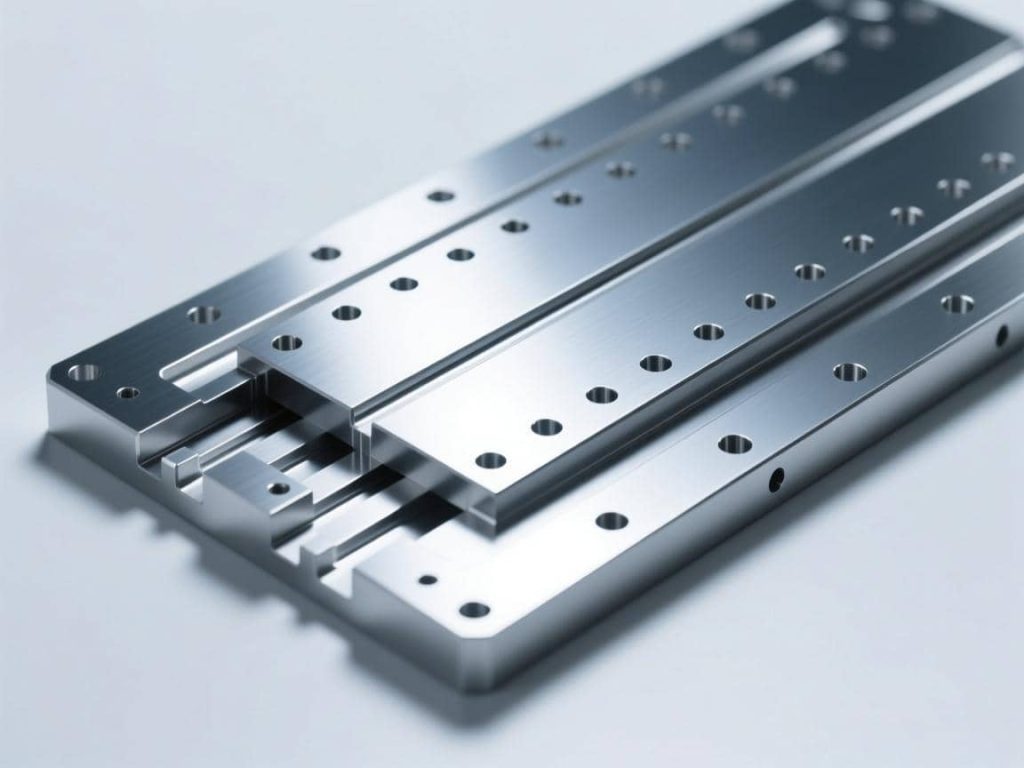

- Extruded aluminum: This is made by forcing molten aluminum through a shaped die. Extruded aluminum is strong and lightweight, and it can be used in a variety of applications where complex shapes are required.

- Rolled aluminum: This is made by passing molten aluminum through rollers. Rolled aluminum is strong and versatile, and it can be used in a wide variety of applications.

- Sheet aluminum: This is made by rolling aluminum into thin sheets. Sheet aluminum is lightweight and easy to work with, and it is used in a variety of applications, including construction, packaging, and electronics.

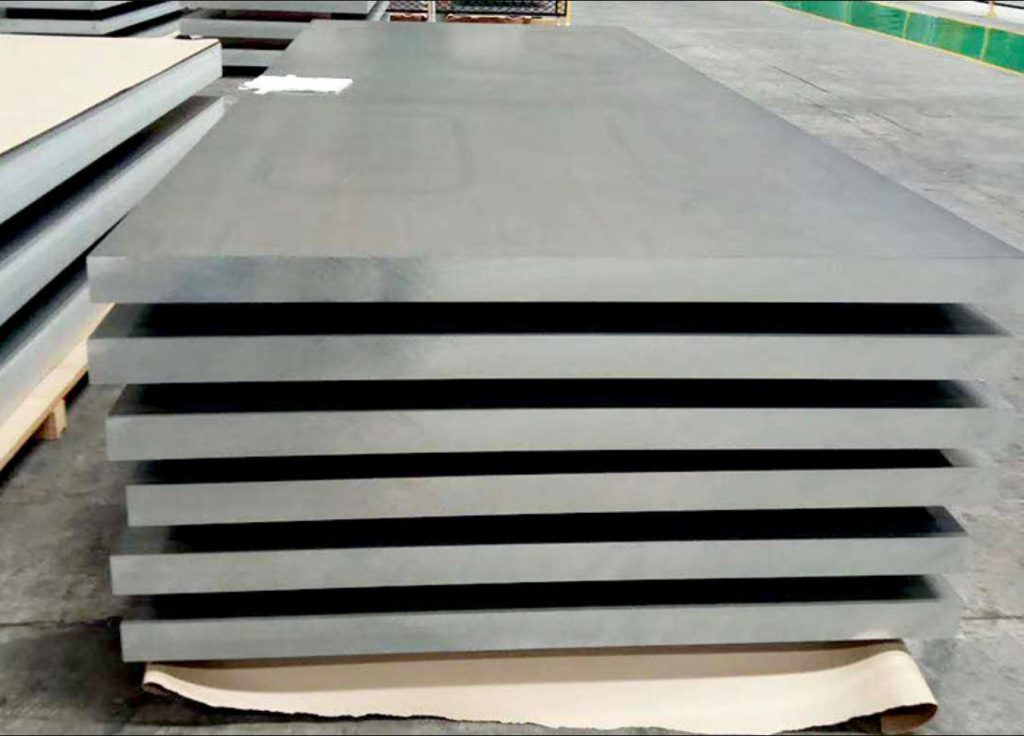

- Plate aluminum: This is made by rolling aluminum into thick plates. Plate aluminum is strong and durable, and it is used in a variety of applications, including machinery, construction, and transportation.

The specific type of aluminum substrate that is best for a particular application will depend on the required properties and desired performance.

What Type of CTP is Used in Aluminum Substrates?

There are two main types of CTP used to make aluminum substrates: laser CTP and thermal CTP.

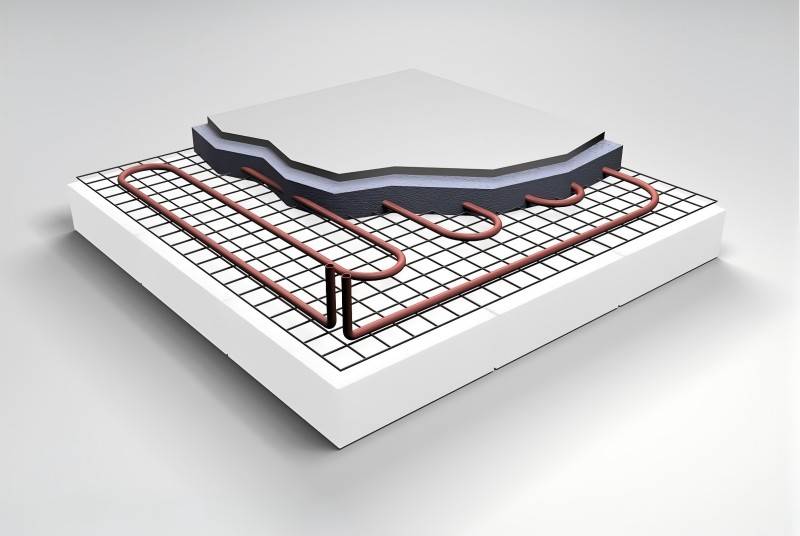

- Laser CTP: This is the most common type of CTP used to make aluminum substrates. It uses a laser to create the printing plate. The laser is focused onto the plate, which is coated with a photosensitive emulsion. The emulsion is hardened where the laser hits it, and it is then washed away, leaving the image on the plate.

- Thermal CTP: This type of CTP uses heat to create the printing plate. The plate is coated with a thermal emulsion, which changes color when it is heated. The image is then created by passing the plate over a heated roller. The areas that are heated turn black, and the areas that are not heated remain clear.

The type of CTP that is used to make aluminum substrates will depend on the specific application. Laser CTP is generally preferred for high-quality printing applications, while thermal CTP is more cost-effective for lower-quality applications.

How CTP is Revolutionizing the Production of Aluminum Substrates?

CTP is revolutionizing the production of aluminum substrates in a number of ways. Here are some of the benefits of using CTP for aluminum substrates:

- Faster turnaround times: CTP can produce printing plates much faster than traditional film-based printing methods. This can lead to faster turnaround times for printing jobs, which can be important for businesses that need to get their products to market quickly.

- Higher quality prints: CTP can produce high-quality prints with fine details and sharp edges. This is because CTP uses a laser to create the printing plate, which is a more precise process than using film.

- Reduced costs: CTP can help to reduce costs by eliminating the need for film. Film is a relatively expensive material, and it can also be time-consuming to process.

- Improved sustainability: CTP is a more sustainable printing process than traditional film-based printing methods. This is because CTP eliminates the need for film, which is a non-renewable resource.

Overall, CTP is a more efficient, accurate, versatile, and sustainable printing process than traditional analog printing. This is why it is often used to make aluminum substrates.

Conclusion

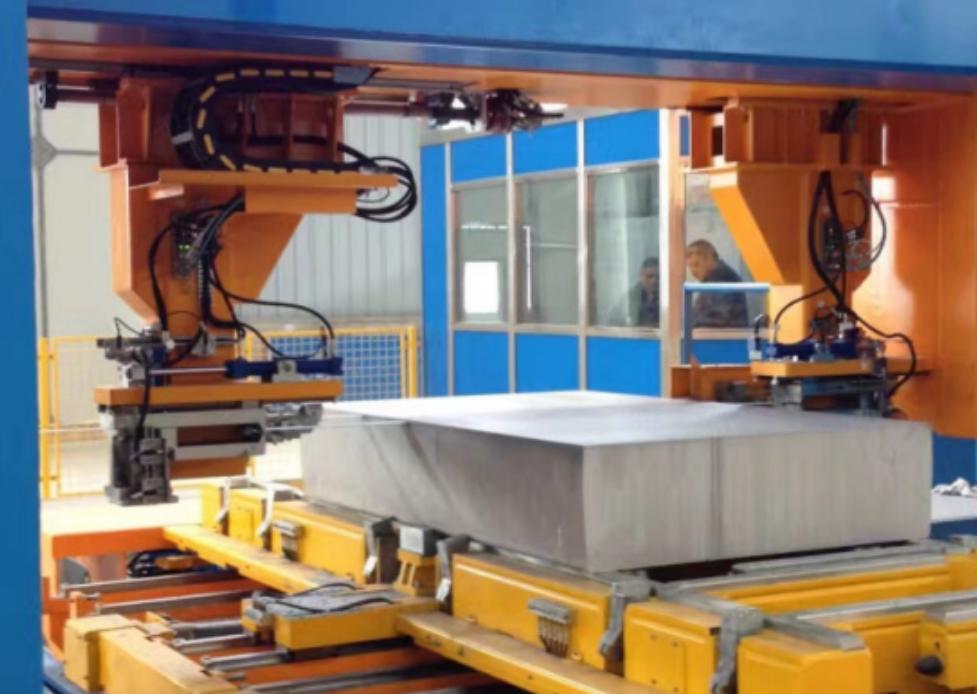

As the printing industry moves towards high-end, personalized, and high-value-added products, the need for high-quality CTP plates is becoming increasingly urgent. In the production of CTP plates, aluminum substrate plates are one of the most important raw materials, and their quality directly affects the quality of the finished product. CHAL is one of the leading CTP aluminum substrate manufacturers & wholesalers in China. If you have any needs please feel free to contact us.