The overall effectiveness of CNC machining ultimately relies on more than programmable tool paths or veteran machinists—it turns on the integrity of the raw stock itself. For anyone responsible for purchasing aluminum billets in a CNC shop, aligning the chemical composition, physical properties, and economic terms of the incoming stock with the performance and cost targets of the bills-of-material is demanding, yet non-negotiably essential. Fortunately, mastering the nuances of alloy behaviour, material certification requirements, and sourcing risks can be codified into a set of practical heuristics.

The pages that follow dissect commonly encountered aluminum grades, crystallize the performance and economic trade-offs into clear thresholds, and steer buyers through the verification and logistics traps that can wreck a machining lot several steps later. We invite you to apply the framework outlined here and to ask the questions that the matrix does not yet answer. With careful calibration of buyers, schedulers, and shop foremen, a single well-chosen batch of aluminum can strike the sweet spot between surface finish, cycle time, and margin.

What Are the Major Aluminum Alloys for CNC Machining?

To evaluate the implementation of CNC machining on aluminum alloys, the categories critical to operational efficiency and material performance merit preliminary clarification. Aluminum alloys are subjected to multiple classification schemes, of which the structuring best informing CNC practice shall be here outlined under the rubric of processing method.

Primary Categorization of Aluminum Alloys Relevant to CNC Machining

By method of processing:

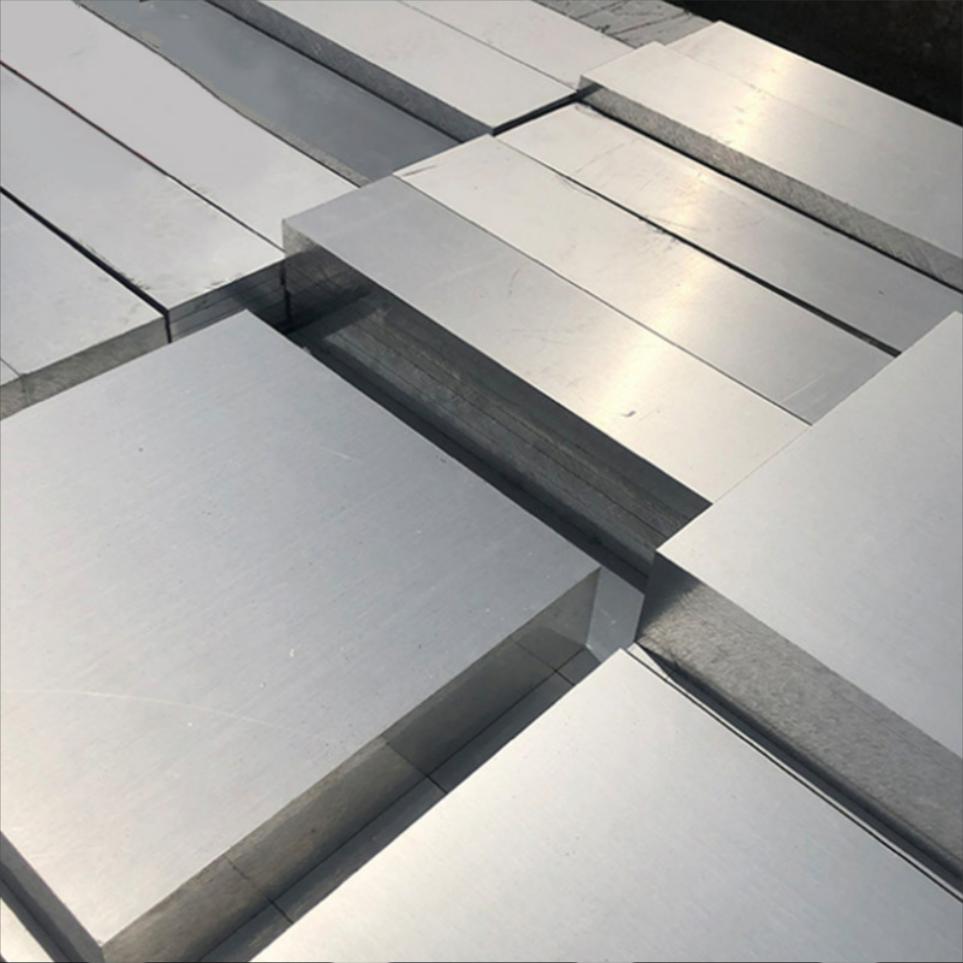

- Wrought aluminum alloys: This subclass encompasses aluminum alloys concentrated through plastic deformation—via techniques of rolling, extrusion, stretching and forging. The resultant materials display a refined microstructure, imparting elevated mechanical performance. In the CNC context, machining is conducted predominantly on semi-finished forms—namely plates, bars, and custom profiles—generated from the deformation route.

- Cast aluminum alloys: This subclass is constituted by alloys molten, then poured and consolidated within a mold. The method is characterised by excellent liquid fluidity, permitting the economical production of geometrically intricate components. Although instances exist in which cast parts undergo secondary CNC refinements, the present discourse shall deliberately restrict itself to the machining of wrought aluminum blocks, which offer predictable responses to the deformation prior, yielding diminished internal defects.

Series classification of deformed aluminum alloys (international four-digit system):

The international four-digit Arabic numeral system serves as the canonical nomenclature for designating the grades of deformed aluminum alloys. Within this system, the leading digit designates the principal alloying constituent, while the remaining three digits differentiate alloys within the same principal group or nominally indicate alloy purity. A concise description of the salient characteristics of each alloy series follows:

| Series | Primary Alloying Element | General Characteristics |

| 1xxx | ≥99.00% Pure Aluminum | Excellent corrosion resistance, high thermal and electrical conductivity, low mechanical strength, and good formability. |

| 2xxx | Copper (Cu) | High strength (can be strengthened through heat treatment), but relatively poor corrosion resistance and fatigue resistance. |

| 3xxx | Manganese (Mn) | Moderate strength, excellent workability, weldability, and corrosion resistance. Cannot be strengthened by heat treatment. |

| 4xxx | Silicon (Si) | Low melting point, good flow properties, wear resistance, commonly used in welding wire and specific casting alloys. |

| 5xxx | Magnesium (Mg) | Moderate to high strength, excellent weldability, and corrosion resistance (especially seawater resistance). Cannot be strengthened by heat treatment. |

| 6xxx | Magnesium (Mg) and Silicon (Si) | Medium strength (can be strengthened through heat treatment), excellent corrosion resistance, weldability, machinability, and good workability. |

| 7xxx | Zinc (Zn) (usually with Mg or Cu) | Very high strength (can be strengthened through heat treatment), the strongest series of aluminum alloys, and good machinability. |

| 8xxx | Other Elements | Developed for specific uses, with a variety of special properties. |

Knowing these basic categories and properties will help us better understand how different aluminum alloys perform and are best used in CNC machining.

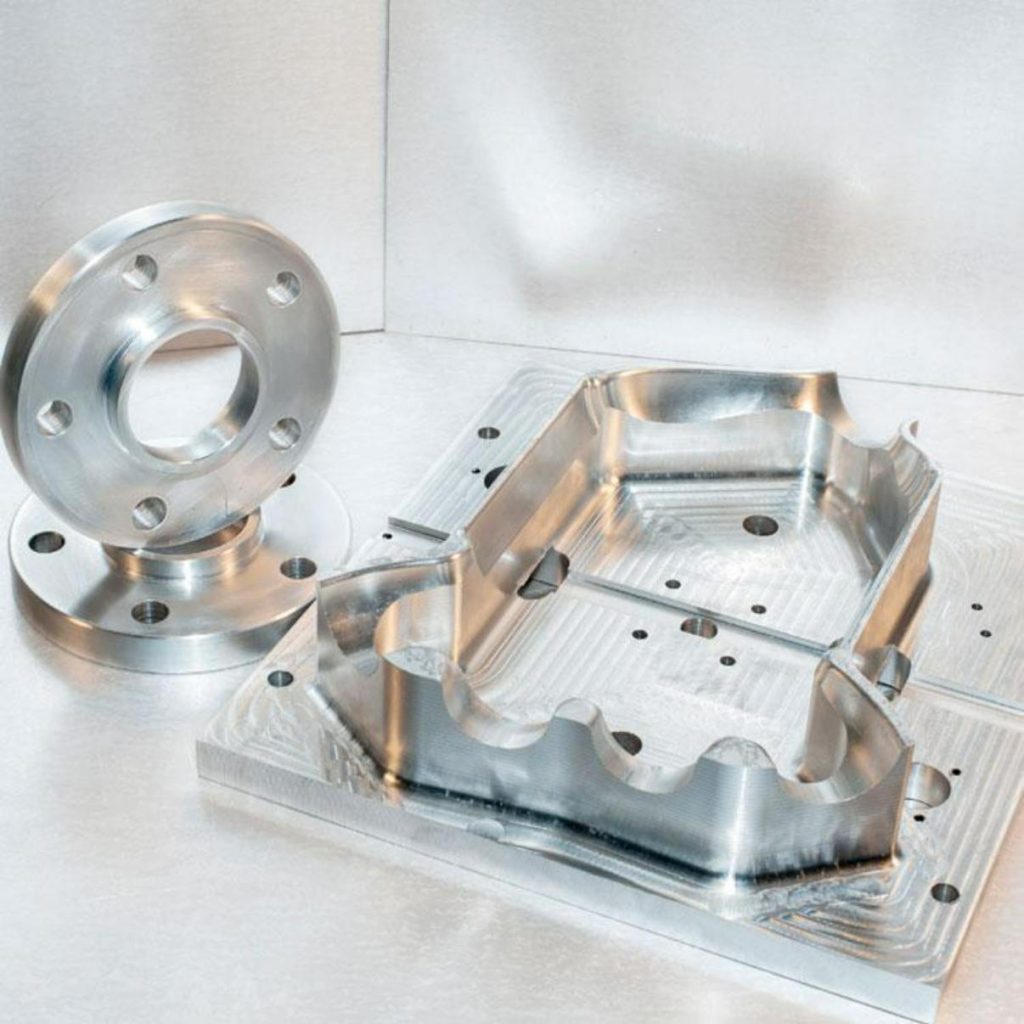

Comparison of Common Aluminum Alloy CNC Machining Performance

Numerous aluminum alloys attract attention in CNC machining because of their favorable part-to-part uniformity, workability, and established inventory streams. The following section examines 6061, 7075, 5052, 2024, and 5083 in detail, allowing designers to align mechanical and thermal objectives with achievable kyros numbers and thereby choose the most appropriate alloy.

| Alloy | Typical Tempers | Key Characteristics | Machinability | Applications |

| 6061 | T6, T651 | Versatile, corrosion-resistant, good strength-to-weight ratio | Excellent | Aerospace, automotive, general parts |

| 7075 | T6, T651, T7351 | High strength, less corrosion-resistant | Moderate | High-stress components, aerospace |

| 5052 | H32, H34 | Excellent corrosion resistance, medium strength | Good | Marine, chemical environments |

| 2024 | T3, T351 | High strength, limited corrosion resistance | Fair | Aircraft structures, military gear |

| 5083 | H112, H116, H321 | Superior corrosion resistance, high fatigue strength | Moderate | Shipbuilding, cryogenics |

Each alloy’s machinability depends on its temper (e.g., T6, T651) and the specific processing requirements.

Steps in Choosing a Block of Aluminum for CNC

Picking the right aluminum alloy for a CNC project calls for a methodical approach. Start with several fitting guidelines:

Step 1: Clarify Project Needs

Don’t look at alloy categories until the client has a well-defined picture of the intended part and the project’s comparative goals. This clarification forms the bedrock for every later step and requires regular back-and-forth with both the engineering team and production supervisors.

- Purpose of the Finished Part: What task will the finished piece perform? Is it a bracket bearing repeat high tensile load, a box shielding delicate electronics, a cart that expels from a heatsink, or a component planned for surgical application? The dominant role foists different criteria on the chosen material. In aerospace, for instance, a mounting rail may seek elevated yield and cyclic durability, whereas a consumer dashboard calls for notable opinion and later polishing.

- Operating Surroundings: What will the piece experience from moment of installation? Ask whether it will sit in brine, freeze at minus 50, profit from evaporating refrigerants, bombarded with caustic reagent, or swaddle in a damp tropical murmur. These surroundings shape the needed level of solder and protective cover. Block for the speichern piece, then, a 5xxx alloy will frequently top the desirables list.

- Mechanical Properties: Determine necessary tensile strength, yield strength, hardness, and flexural modulus. Engineers will supply exact numbers, often indicating a specific temper. For example, a mechanism subject to steady-state bending loads may demand a minimum yield strength of 570 MPa, steering the selection to high-strength tempers like 7075-T6.

- Surface Treatment: Clarify finish and coating expectations: mirror-polished, Type II anodized, or thin-film painted. Alloys exhibit differing machinability, and the readiness of a coating to bond can depend on grain size or native oxide characteristics. Provide finish draw drawings to align the supply and processing capabilities.

- Weight Budget: When payload or mobility matters, set a mass budget. Aluminum displays a low density, yet specific alloys, such as the 2xxx series, punch above their weight in flexural strength. Engineers can calculate the minimum allowable wall thickness and, in turn, guide the optimal strength-to-weight selection.

- Secondary Operations: Anticipate necessary follow-on steps—friction stir welding, precipitation aging, electrophoretic coloring. Not all alloys sustain identical stability in these, and temper sensitivity can restrict the processing window. For instance, 7075-T6 is often machining with addressing edge cracking before a protective anodize; 6061, while less stiff on the curve plate, is more forgiving.

Bounding these parameters early prevents scope creep, distances low-performance alloys, and creates a shortlist of candidates that align with the detailed functional and environmental regimes outlined by project stakeholders. This payoff accelerates engineering evaluation and guards against budgetary pitfalls later in the supply chain.

Step 2: Evaluate Key Selection Indicators

After confirming project requirements, the evaluation proceeds to the intrinsic properties of candidate alloys, where choices typically require trade-offs rather than the identification of an optimal singular material.

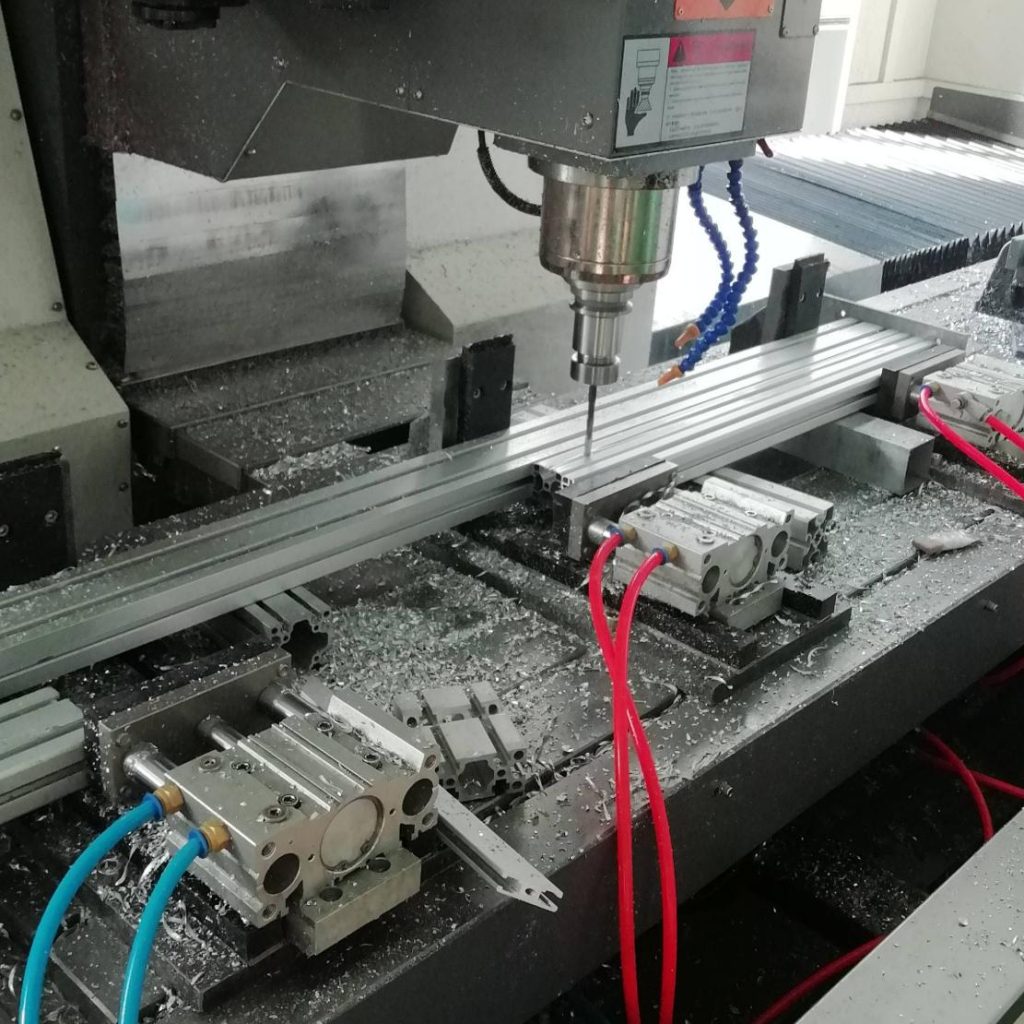

- Machinability

Machinability characterizes the material’s receptiveness to cutting-edge operations in CNC environments. Superior performance in this domain yields shorter cycle times, diminutive flank and crater wear on tools, and superior surface roughness. Alloys such as 6061 manifest demonstrable machinability, creating continuous, short chips conducive to swift evacuation and no significant burr formation. Conversely, 7075—while offering elevated strength—subjects the cutting edges to intensified wear, prolonging tool replacement cycles and decelerating feed rates. Consequently, the evaluation of a prospective alloy must embrace the comprehensive cost of machining, embedding tool life and cycle times, rather than fixating on the basal cost of the blank.

- Strength vs. Ductility

The customary correlation between yield strength and ductility invites a careful balancing act. Increased strength—obtained via alloying and thermal treatment—frequently diminishes the material’s capacity to undergo plastic deformation without fracture. Structural components subjected to dynamic loading must therefore be scrutinized for an optimal strength-ductility ratio; for a primary load-carrying bracket subjected to cyclic stress, modest increases in tensile properties may offer diminishing returns if the alloy resists localized yielding and, consequently, kinetic stress-relaxation. A design statement asserting high rigidity, yet bearing a ductility spec well beneath the expected plastic hinging requirements, may retreat violently in the production calendar.

- Corrosion Resistance

Corrosion resistance constitutes the capacity of metallic materials to avert deterioration through chemical interactions with their operational milieu. data presented in the associated table confirms that the 5XXX families of alloys are the leaders in this property, thus validating their preferred application in marine ambiences and chemical transport or storage apparatus. The 6061 variant also presents an acceptable, broad-based resistance, yet its performance may fall short under severe, aggressive environmental combinations.

- Weldability

Weldability becomes an overriding consideration when a component assembly demands the fusion of multiple aluminum specimens. Alloys with elevated copper or zinc contents—specifically those of the 2XXX and 7XXX families—demonstrate pronounced difficulties, sometimes approaching intractability, when conventional welding protocols are deployed. The resultant microstructure may exhibit a weakened or embrittled nexus, necessitating recourse to highly specialized procedures elevated in operational complexity and, potentially, cost.

- Anodizing Response

The electrolytic anodizing of aluminum, widely employed to augment corrosion endurance and to afford a decorative coloration, elicits divergent reactions from discrete alloy families. The 6061 alloy, in particular, undergoes a predictable and homogeneous anodic transformation that furnishes an aesthetically pleasing façade. Contrariwise, select alternative alloys may exhibit pronounced variability, yielding a surface quality characterized by a muted or ‘muddy’ chromatic expression, thus mediating constraints that are of particular relevance to occupants of the decorative and protective coating supply chain.

- Cost (Material and Processing)

Cost assessment is inherently multidimensional. The nominal price per pound of raw aluminum billet designated for CNC machining is only one visible indicator. Thus, a more relevant metric is the total cost of ownership (TCO), which aggregates not only single-unit price but also incremental machining, tooling, and scrap expenses. For example, a price-attractive alloy that incurs a doubling of spindle time, accelerates end-mill wear, and yields a 15-20 percent waste rate, may present a grand total that exceeds that of a higher-price but faster, more stable alloy. Conversely, a structurally over-specified alloy employed in a non-load-bearing accumulator housing adds excess upfront observables and may deliver nominal extra lifespan, resulting in negative efficiency for both the balance sheet and environmental footprint. Through the explicit modelling of machining time, tooling cycles, and expected yield fees, purchasing personnel can forge explicit scenarios alongside R&D and shop-floor supervision, thus isolating the implicit-value space where cost, performance, and manufacturability converge in the largest aggregate of operative and economic efficiency.

Step 3: Practical Selection for Typical Applications

To put the theory into practice, let’s consider a few common scenarios and the typical alloy choices:

| Part Type/Application Scenario | Preferred Aluminum Alloy (Typical Temper) | Key Reasons for Selection |

| General Structural Components(e.g., machine frames, jigs, fixtures, prototyping, non-critical automotive parts) | 6061 (T6, T651) | Excellent balance of strength, corrosion resistance, and machinability; widely available and cost-effective. T651 is stress-relieved for improved stability. |

| High-Stress/Aerospace Parts(e.g., aircraft structural components, heavy-duty machinery parts, defense components, molds requiring high hardness) | 7075 (T6, T651, T7351) | Highest strength among common aluminum alloys; excellent fatigue resistance. T7351 offers improved stress-corrosion cracking resistance. |

| Marine/Corrosive Environment Parts(e.g., boat components, saltwater exposed parts, chemical processing equipment, fuel tanks) | 5052 (H32, H34)5083 (H112, H116, H321) | Exceptional corrosion resistance, especially in saltwater. 5052 has good formability; 5083 offers higher strength and excellent weldability. |

| High-Strength Aircraft Parts (Good Fatigue Life, Less Extreme than 7075)(e.g., aircraft fittings, rivets, some structural elements) | 2024 (T3, T351) | High strength and superior fatigue resistance compared to 6061. T351 is stress-relieved for dimensional stability. |

| Heat Sinks/Heat Exchangers(e.g., LED housings, electronic cooling plates) | 6061 (T6)1100 (H14, H18) | 6061 offers good thermal conductivity, strength, and machinability. 1100 provides even higher thermal conductivity but is softer. |

| Cosmetic/Anodized Parts(e.g., consumer electronics enclosures, decorative panels) | 6061 (T6)5052 (H32, H34) | Both anodize well for consistent, attractive finishes. 6061 is preferred for machined parts; 5052 for formability. |

These examples highlight that the selection process is not theoretical; it requires practical application of knowledge to real-world problems. By matching the component’s required performance characteristics with the appropriate aluminum alloy, purchasers can optimize both the manufacturing process and the final product’s functionality.

Step 4: Prevent Expensive Errors

Acquaintance with material characteristics does not suffice when stereotypes persist. What follows enumerates the most widespread fallacies and prescribes preparatory remedies.

Fallacy 1: “Excess Strength is Universally Advantageous”

This belief misapplies the strength property in regimes with differing requirements. Materials of superior strength may exhibit poor machinability, reduced ductility, and elevated expense. Stipulating an alloy of excessive tensile capacity for an ornamented exterior component not only wastes expenditure but also may hinder achieving target tolerances. Design for an alloy whose yield strength approximates the peak anticipated load rather than placing strength first by reflex.

Fallacy 2: “Aluminum, by Definition, Resist Corrosion”

Aluminum’s surface does indeed form a protective oxide, yet corrosion behaviour does not linearise across its alloy series. 2xxx-type products, alloyed primarily with copper, suffer pit propagation, especially in marine or acid exposure, while 5xxx and 6xxx grades ordinarily exhibit superior performance in analogous regimes. Appeals lodged solely on “aluminum” labels cannot replace alloy-specific corrosion education in the specifications.

Fallacy 3: “Price Per Unit Mass Always Optimises Total Expenditure”

Commercial wisdom too swiftly embraces lowest masses costs without accruing total cost of ownership metrics. Municet toughness in a material may indeed reduce its basic purchase cost while accelerating drill and insert degradation, extending cycle times and raising workpiece fall-out. Equally, derivatives labelled as ‘proprietary’, lack mill certification and guarantee. Hidden within naïve purchasing rational is an invitation to cite dimensionally and financially irreversible.

In summary, thwarting these hazards requires a rigorous assessment of preprocessing design versus material performance, rather than succumbing to reflex purchasing decisions.

Tips for a Smooth Procurement Process

Beyond the initial selection of aluminum stock for CNC operations, the entire procurement sequence harbors risks that, if mismanaged, can compromise delivery, quality, and operational productivity. A disciplined approach from requisition to receipt minimizes disruption.

Accurate Specification Communication: Specifications must be precise and redundant. Include alloy designation, temper, net and gross dimensions, net and excess tolerances, distinct quantity for stock and for specific jobs, and any surface finish, grain, or machining stock stipulations. Wherever practical, cite CAD part classifications or attach schematic references. Imputation of intent is prohibited.

Material Certification Requirements: Demand comprehensive Material Test Certification accompanying each shipment. Mill Test Reports must detail chemical, mechanical, and, if applicable, thermal treatment properties. Accept only material that meets both the referenced industry standard and the requisition specification. For parts whose performance is safety or regulatory-sensitive, verification is mandatary.

Lead Time Planning: Integrate aluminum procurement into the broader production timeline. Identify anticipated stock-in dates through backward scheduling, being mindful that certain alloys and dimensions can incur production delays of weeks. Prevent operational bottlenecks through advanced requisition, especially if balancing raw material runs across batch process centers. Protocols for maintaining controlled, minimal buffer inventories of high-rotation alloys mitigate quick-stock shortages.

Consolidation and Volume Discounts: Assess the feasibility of combining requisitions across multiple work orders to exploit bulk terms. Bulk purchasing not only reduces unit material costs but can also compress logistics costs, as long-haul shipping and extrusion setup overheads are amortized. Where the net stack aligns with the chemical and mechanical uniformity procedures, centralized auditing and quality release measures can be employed for even appendix standardized procurement zones.

Choose a Reliable Block of Aluminum for CNC Supplier

The last and no less important choice is picking the right provider for your aluminum block intended for CNC work. You can outline the material down to the grain size, but an inferior producer can squander the whole specification job.

- Legacy and Expertise: Seek out vendors celebrated for consistent CNC-grade aluminum supply. Look at reviews, scan industry press mentions, and find out how many cycles of business those firms have logged.

- QC Protocols: Ask how they assure the incoming lom material clarity. Are the billets routinely spectro-analyzed? What happens to an alloy that barely misses the mark? A detailed, industry-recognized certification like ISO is one solid stamp of pedigree.

- Certification Documentation: A trustworthy source promptly hands over complete mill test reports. If they stutter or stall in releasing the standard metallurgical notes, consider that a red flag.

- Stock and Scheduling: A capable vendor keeps the aluminum tape in the right alloys and stock plates, cutting avoidable waiting. For rarer chemistries or oversized splits, they should lay out the sourcing network and the predictable calendar.

- Service and Dialogue: Notice how smoothly your inquiry cycles through their mμachining desk. Quick, clear, courteous exchanges usually foreshadow the final transaction, and the support infrastructure they put in place.

In short, there’s no one-size-fits-all aluminum alloy. The best choice depends on thoroughly understanding your specific needs and carefully considering the material’s properties.