Aluminum sheets are versatile materials widely used across various industries for their lightweight, corrosion-resistant, and durable properties. But within the world of aluminum sheets, there’s a key distinction to consider: hardness. Selecting between hard and soft aluminum sheets depends entirely on your project’s specific needs. This article will guide you through the properties and applications of each type, empowering you to make the perfect choice.

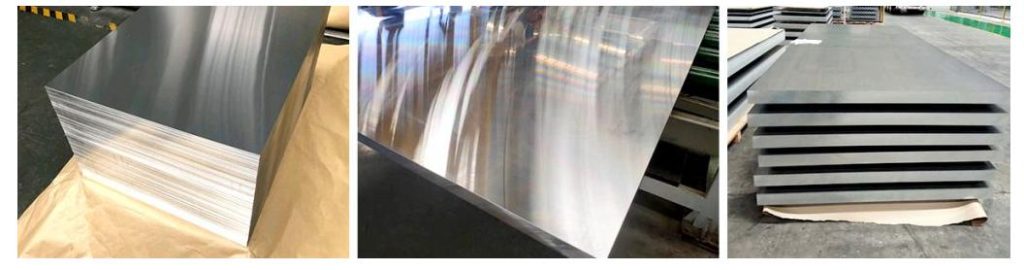

Properties of Hard Aluminum Sheets

Hard aluminum sheets are a type of aluminum sheet that has been treated to increase its strength. This is typically belonging to the 2XXX, 6XXX, and 7XXX series, done through a process called cold working, which involves rolling the sheet metal at room temperature. Cold working creates defects in the crystal structure of the metal, which makes it harder but also more brittle.

Here are some of the key properties of hard aluminum sheets:

- High strength: Hard aluminum sheets are significantly stronger than pure aluminum sheets. This makes them suitable for applications where the sheet metal will need to bear a significant load.

- Good formability: Despite being harder than pure aluminum, hard aluminum sheets can still be formed into complex shapes. However, they will require more force to bend than softer aluminum sheets.

- Good machinability: Hard aluminum sheets can be machined using a variety of techniques, including drilling, milling, and sawing. However, they may require specialized tooling due to their increased hardness.

- Corrosion resistance: Hard aluminum sheets inherit the excellent corrosion resistance of aluminum. They can form a thin oxide layer on their surface that protects them from further corrosion.

- Lightweight: Aluminum is naturally lightweight, and hard aluminum sheets are no exception. This makes them a good choice for applications where weight is a major consideration, such as in aerospace and automotive applications.

Applications of Hard Aluminum Sheets

Hard aluminum sheets find extensive use in industries where strength, durability, and precision are paramount. Common applications include:

- Transportation: Hard aluminum sheets are used in a variety of transportation applications, including aircraft, automobiles, and trucks. Their high strength-to-weight ratio makes them ideal for components that need to be both strong and lightweight. For example, hard aluminum sheets are used in aircraft wings, fuselage panels, and engine components. In automobiles, they are used for hoods, trunks, and wheels.

- Construction: Hard aluminum sheets are also used in construction applications, such as roofing, siding, and wall panels. Their strength and durability make them resistant to weather and corrosion.

- Marine: Because of their good corrosion resistance, hard aluminum sheets are used in boat hulls, decks, and superstructures.

- Consumer goods: Hard aluminum sheets are used in a wide variety of consumer goods, such as sporting goods, appliances, and electronics. Their strength and durability make them ideal for products that need to withstand wear and tear. For example, hard aluminum sheets are used in baseball bats, bicycle frames, and appliance housings.

- Industrial applications: Hard aluminum sheets are used in a variety of industrial applications, such as machinery, tools, and dies. Their strength and wear resistance make them ideal for components that need to withstand high stresses.

The specific applications for hard aluminum sheets will depend on the alloy used and the temper (degree of hardness) of the sheet. There are many different types of hard aluminum sheets available, each with its own unique properties. We give you some recommends in the following part.

Properties of Soft Aluminum Sheets

Soft aluminum sheets, also known as commercially pure aluminum sheets, refers to aluminum sheets that have undergone a process to achieve a low level of temper, and typically belonging to the 1XXX, 3XXX and 8XXX series. They undergo minimal processing during manufacturing, retaining their inherent flexibility and pliability. Soft aluminum sheets can be easily bent, folded, or shaped using common fabrication techniques such as bending, rolling, or stamping. Despite their lower mechanical strength, they offer excellent formability and adaptability to complex geometries.

They are known for several key properties:

- High ductility: This means the material can be easily stretched or deformed into different shapes without breaking. This makes it ideal for applications that require a lot of bending or forming, such as food packaging or gutters.

- Softness: As the name suggests, soft aluminum sheets are very malleable and easy to work with. They can be cut, stamped, and drilled with minimal force.

- Lightweight: Aluminum is naturally lightweight, making it a good choice for applications where weight is a concern, such as aircraft construction or automotive parts.

- Good electrical conductivity: While not as conductive as pure copper, soft aluminum still conducts electricity well. This makes it useful for applications like busbars and heat sinks.

- Excellent corrosion resistance: Aluminum naturally forms a thin oxide layer that protects it from corrosion. This makes it suitable for use in outdoor environments or with some chemicals.

However, it’s important to note that due to its softness, pure aluminum sheets lack the high strength of some other metals. To improve strength, aluminum is often alloyed with other elements like copper, magnesium, or silicon. These alloys sacrifice some ductility and conductivity for increased strength, making them more suitable for structural applications.

Applications of Soft Aluminum Sheets

Soft aluminum sheets are often used in applications where flexibility and malleability are desired. Some common uses include:

- Food and beverage packaging: Soft aluminum sheets are widely used to manufacture beverage cans, food containers, and closures. The formability allows for easy shaping into containers, while the corrosion resistance protects the food inside.

- Building and construction: Soft aluminum sheets are used for roofing panels, siding, gutters, and flashing due to their lightweight nature, formability, and weather resistance.

- Heat exchangers: Soft aluminum sheets are used in heat exchangers because of their excellent thermal conductivity, which allows for efficient heat transfer.

- HVAC ductwork: They are used in heating, ventilation, and air conditioning (HVAC) systems due to their lightweight nature, ease of fabrication, and good corrosion resistance.

- Appliance parts: Many appliance parts, such as oven liners, are made from soft aluminum sheets because of their formability and heat resistance.

- Decorative applications: Soft aluminum sheets can be formed into decorative elements due to their workability.

When choosing a soft aluminum sheet for a particular application, it’s important to consider the specific temper (degree of hardness) of the sheet. The temper designation will typically start with a capital “H” followed by a number, with higher numbers indicating a harder temper. Soft aluminum sheets will typically have a temper designation of H1 or H2.

How to Choose Between Soft and Hard Aluminum Sheets?

Consider these factors when choosing between hard and soft aluminum sheets:

- Project Requirements: Prioritize strength and rigidity. Opt for hard aluminum. Need easy shaping and forming? Soft aluminum is your pick.

- Fabrication Techniques: If your project involves complex bends or intricate details, soft aluminum’s workability is advantageous. Conversely, for projects requiring specialized tools to handle strong materials, hard aluminum might be suitable.

- Weight Considerations: In weight-sensitive applications, soft aluminum’s lighter nature might be a deciding factor.

Here are choosing considerations and representative grades of soft and hard aluminum:

| Consideration | Soft Aluminum Sheets | Hard Aluminum Sheets |

| Flexibility vs. Rigidity | More flexible and bendable | More rigid and resistant to bending |

| Strength Requirements | Generally less strong | Higher strength and durability |

| Machinability | Easier to machine and work with | More difficult to manipulate but offer better precision |

| Corrosion Resistance | Excellent corrosion resistance, slight variation in hard sheets | Excellent corrosion resistance |

| Cost | Generally more affordable | Can be more expensive |

| Application Specifics | General fabrication, signage, food packaging | Structural applications, aerospace, automotive |

| Availability and Size | Widely available, various sizes | Available, but less common, various sizes |

| Representative Grades | 1100, 3003, 5052 | 2024, 6061, 7075 |

Conclusion

In conclusion, the choice between hard and soft aluminum sheets hinges on a careful assessment of the project’s functional requirements, manufacturing constraints, and performance expectations. Hard aluminum sheets offer superior strength and durability, ideal for structural applications in aerospace, automotive, and construction sectors. Conversely, soft aluminum sheets excel in applications where formability, versatility, and aesthetic appeal are paramount, such as packaging, architecture, and consumer goods. By understanding the distinctive properties and applications of hard and soft aluminum sheets, you can make informed decisions to optimize the performance and efficiency of your projects. If you are looking for a hard and soft aluminum sheet supplier, please consider CHAL. Believe they will not let you down.