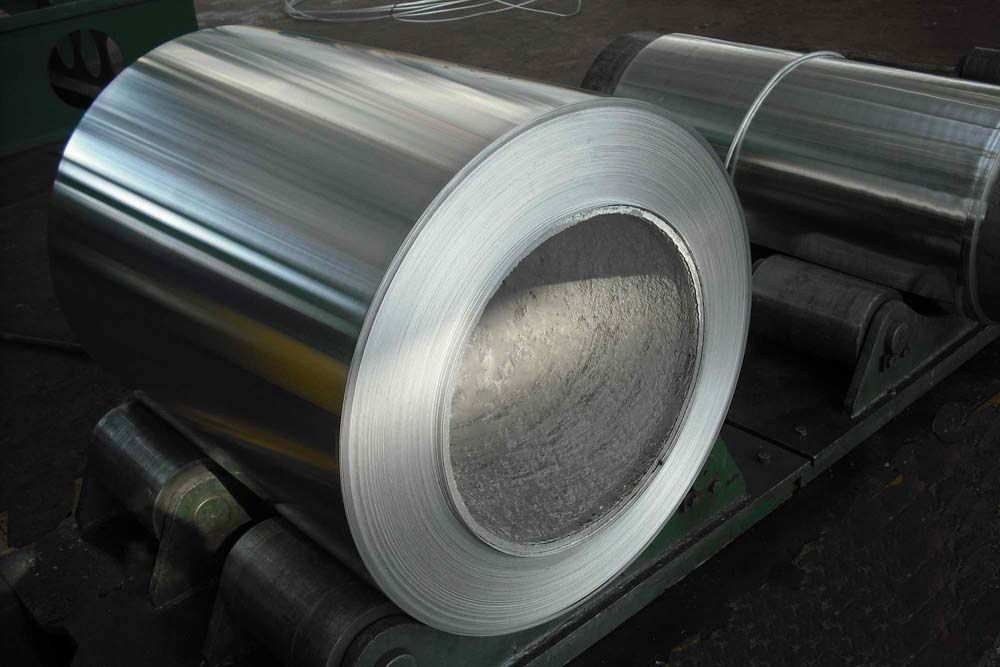

Aluminum cans are cans which are made of aluminum coils. The aluminum can is composed of a can lid, a pull ring, a can body and a can bottom. Aluminum cans are the most common packaging materials for beverages such as coke, sprite, beer, etc. in daily life. Besides, they are more environmentally friendly than other packaging containers.

1. What type of aluminum is used in aluminum cans?

Aluminum cans are mainly composed of aluminum alloys with different components: 3004 aluminum coil for the can body, 5052 aluminum alloy/ 3014 aluminum alloy for the can lid, 3104 aluminum alloy for the can bottom, and 5182 aluminum alloy for the can pull ring. To help you know clearly, here are tables in the following:

|

Aluminum in Cans |

|

|

Parts of Can |

Aluminum in Cans |

|

Body |

3004 aluminum alloy |

|

Pull ring |

5182 aluminum alloy |

|

Lid/bottom |

5052/3104 aluminum alloy |

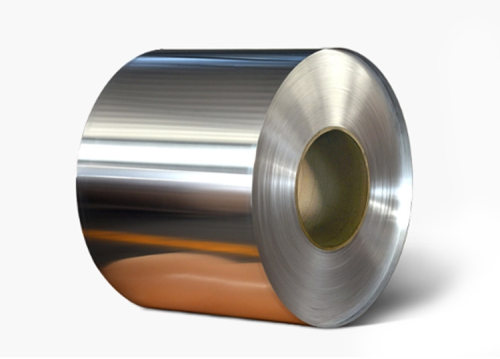

3004 aluminum coils are mainly used for bodies of aluminum cans. The 3004 aluminum coil is a variant of the 3003 aluminum alloy. It has good formability, weldability, and corrosion resistance so it is mostly used for processing and requires good formability and high corrosion resistance. The products like aluminum cans made with the 3004 aluminum coil are good solderability.

Both 5052 aluminum alloys and 5182 aluminum alloys belong to aluminum-magnesium alloy, and both of them have good corrosion resistance, weldability, good cold workability, and medium strength, and their surfaces are very bright after polishing. However, the 5182 aluminum alloy has a higher magnesium content than the 5052 aluminum alloy, and a small amount of silicon is added so the weldability is better than that of the 5052 aluminum alloy. Therefore, the 5052 aluminum alloy is mostly used for aluminum can lids, and the 5182 aluminum alloy is mostly used for pull rings of aluminum cans.

3104 aluminum alloy is commonly used at the bottom of cans. 3104 aluminum plate is a deformed aluminum alloy, the tensile strength is greater than or equal to 275MPA, and the elongation can reach 20%. It has good deep drawing performance.

Specification of aluminum alloy used in aluminum cans

| Specification of Aluminum Alloy Used in Aluminum Cans | ||||

| Type of aluminum alloy | Tensile strength/Mpa | Elongation/% | Yield strength/Mpa | Thickness/mm |

| 5052 Aluminum alloy | 270-330 | ≥5 | 240-300 | 0.2-0.36 |

| 3104 Aluminum alloy | 270-320 | ≥5 | 240-280 | 0.2-0.36 |

| 5182 Aluminum alloy | 360-410 | ≥6 | 310-360 | 0.25-0.5 |

2. What advantages of aluminum alloys used in cans?

- Lightweight

Compared with tinplate, the density of aluminum alloy is one-third of that of iron. Aluminum cans are lightweight, heat-resistant, have good conductivity, are non-toxic and tasteless, and good printing effect.

- Anti-corrosion

3/5 series aluminum alloy is a typical anti-rust aluminum, which is anti-oxidation, durable and recyclable, economical and environmentally friendly, and can resist acid and alkali corrosion. Thus, the aluminum can is recyclable and anti-oxidation.

- Good seam welding

5182 aluminum alloy has silicon elements, and the welding performance of gas welding, argon arc welding, spot welding, and seam welding is very good.

- Good machinability

Aluminum alloys are very suitable for post-processing such as slitting and slicing. Thus, aluminum cans are good machinability.

3. What is the process of making aluminum cans?

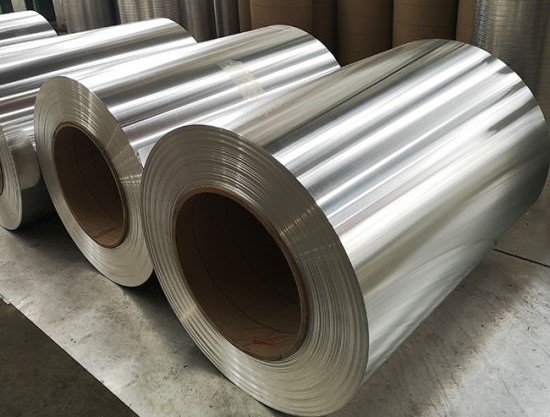

- Open the aluminum coil for lubrication.

- Send the aluminum plate to the cupping machine for cupping.

- The aluminum cup becomes an aluminum can after multiple stretches.

- Clean and dry the aluminum can.

- Spray the aluminum can multiple times.

- Shrink the aluminum can and neck flanging.

- Take pictures to inspect aluminum cans.

From the introduction above, you already have a certain understanding of aluminum cans. As for CHAL aluminum coil, we supply aluminum sheet coil and aluminum foil coil in a wide variety of alloys and thicknesses. We CHAL Aluminum Corporation is a fully integrated aluminum manufacturer and supplier that provides all kinds of aluminum products and technical solutions. We are committed to being the leading supplier of aluminum plate, cast tooling aluminum plate, aluminum sheet (clad or bare), aluminum foil (clad or bare), aluminum strip (slit coil), aluminum circle, and aluminum coil. If you have any interested products please feel free to contact us. We are so glad to serve your needs.