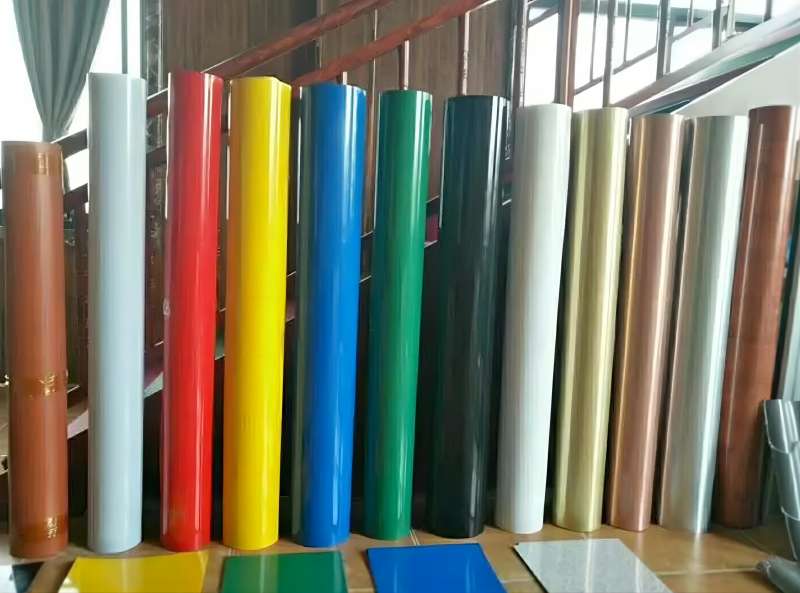

Color-coated aluminum coils are the surface coating and coloring treatment of aluminum plates or aluminum coils. The commonly coated aluminum coils are fluorocarbon color-coated aluminum coils and polyester color-coated aluminum coils. They are widely used for Veneer, aluminum honeycomb panels, aluminum ceilings, roof surfaces, leftover material, cans, and electronic products. The performance of the color-coated aluminium coil is very stable, and not easy to corrode. Besides, the surface layer of the color-coated aluminum coil can achieve 50 years of quality assurance after special treatment. The weight of them per unit volume is the lightest among metal materials. Color-coated aluminum coils are currently the most popular new material.

Types of Color-Coated Aluminum Coils

The color-coated aluminum coils are divided into polyester-coated aluminum coils (PE), and fluorocarbon-coated aluminum coils (PVDF) on the basis of the coating. The polyester coating formed by baking the surface of the aluminum plate many times can form solidly adhered continuous solid films that have protective decorative properties. It is an anti-UV coating. The polyester resin is made of a high molecular polymer containing ester bonds in the main chain, and an alkyd resin is added. The ultraviolet absorber can be divided into matt and high-gloss series according to the gloss. It can endow aluminum products with rich colors, good gloss and smoothness, as well as superior texture and feel. In addition, it can also increase the sense of layering and three-dimensionality of aluminum products. It can protect objects exposed to the atmosphere and being attacked by ultraviolet radiation, wind, rain, frost, and snow. Due to temperature differences, freeze-thaw cycles, corrosive gases, and microorganisms, the coating can play a protective role. The color-coated aluminium coil is especially suitable for interior decoration and advertising boards.

Fluorocarbon coatings of fluorocarbon polyester-painted aluminum coils are PVDF resins, mainly referring to vinylidene fluoride homopolymers or copolymers of vinylidene fluoride and other small amounts of fluorine-containing vinyl monomers. Fluorocarbon coatings can be divided into traditional fluorocarbon coatings and nano-fluorocarbon coatings according to the surface film formation structure. The fluorocarbon polyester color-coated aluminum coils are especially suitable for the decoration and display of indoor and outdoor decorations in public places, commercial chains, exhibition advertisements, etc.

Characteristics of color-coated aluminum coils

These coated aluminum coils have the feature of flatness.

There is no compound high-temperature indentation on the surface. The board surface has no residual tension and no deformation after shearing.

- These coated aluminum coils are decorative.

Color-coated aluminum coils are painted with wood grain and stone grain so it has a realistic physical texture and a vivid natural beauty. The pattern can be made at random, giving customers a wide range of individual choices, enriching the humanistic connotation of the product, and giving people more aesthetic enjoyment.

- These painted aluminum coils are weather resistance

The baked varnish pattern formed by continuous coating and high-temperature baking has high gloss retention, good color stability, and minimal change in color difference. Polyester paint on color-coated aluminum coils has a 10-year warranty, and fluorocarbon paint on color-coated aluminum coils has a 20-year warranty.

- Color-coated aluminum coils are mechanical.

High-quality aluminum materials, plastics, and adhesives are selected, and advanced composite technology is adopted. The Color coated aluminum coils have the bending and flexural strength required by the decorative board. In the four seasons, the change in wind pressure, temperature, humidity, and other factors will not cause bending, deformation, expansion, etc.

- Color-coated aluminum coils are environmental protection.

Corrosion resistance to saline-alkali acid rain, color-coated aluminum coils will not corrode and produce poisonous bacteria, will not release any toxic gas, will not cause keel and fixing parts to rust, and is flame retardant.

Applications of color-coated aluminum coils

Color-coated aluminum coils have a rich range of colors. Whether they are residential buildings, large commercial outlets, or large-scale convention centers, color-coated aluminum coils can add color to them. The good plasticity and machinability of the coated aluminum coil make it an ideal material for various architectural shapes. Color-coated aluminum coils have given architects, designers, and owners a bespoke color space for outside walls and ceilings, and they are the best material for architectural modeling. Whether it is a multi-functional large building or a unique and creative new building, the color-coated aluminum coil can always meet the different requirements of modern and classical architectural styles and make the building more colorful. Color-coated aluminum coils are used in many fields such as electronic appliances, instruments, lighting, packaging, and home decoration.

By the way, if you want to know the methods of coating aluminum coil, please click here.