Aluminium foil is a thin sheet of metal foil comprising about 92-99% aluminum. Its thickness is typically between 0.0002 to 0.006 inches. Its width and intensity are very different due to expected applications. It is a material that is durable, non-toxic, and oil-proof, which can resist chemical erosion.

There are many uses of aluminum foils that are well known. So how did people discover the use of aluminum foil? Why is it so popular? Is it harmful to the human body? These issues will answer one by one.

History of Aluminum Foil

On the market, People have different opinions on the application history of aluminum foil, but most of them support the use of aluminum foils starting from the beginning of the 20th century.

The origin of aluminum foil can be traced back to the early 1900s. A confectionery was first using aluminum foil packaging in 1913. Today, candies still use aluminum foil packaging. In the past 100 years, the use of aluminum foil has grown to almost endless quantity. From Christmas tree decorations to spacecraft insulation, from TV dinner to the pharmacy – aluminum foil improved our products and our lives in many ways.

Production of Aluminium Foil

Aluminum is one of the most abundant elements: after oxygen and silicon, it is the most abundant element found on the surface of the earth, with more than 8% of the earth’s shell, with a degree of 10 miles, almost every common rock. However, aluminum is not present in the form of pure metal, it is in the form of a combination of hydrated alumina (mixture of water and alumina) to silica, iron oxide and titanium dioxide. Such a large amount of aluminum material has laid a certain basis for the manufacture and application of aluminum foil.

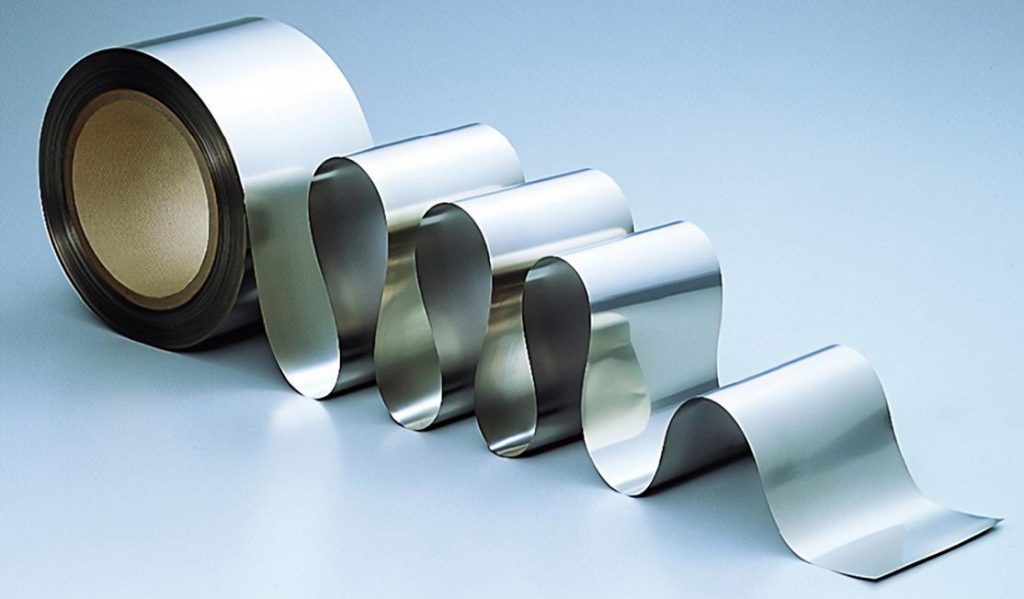

Aluminum foil is produced by rolling aluminum slabs cast from molten aluminum in a rolling mill to the desired thickness. To maintain a constant thickness, a technician monitors the rolling mill sensors to ensure the pressure on the slab is correct. Sensors are able to tell the technician if the pressure is too great or not enough and then the technician can adjust the rollers to apply more or less pressure. It is then coiled and sent to the cold rolling mill.

To avoid breakage because of the thinness, the foil is doubled in the cold rolling mill and rolled to the desired thickness. Aluminum foil provides a complete barrier to light, oxygen, moisture and bacteria. For this reason, foil is used extensively in food and pharmaceutical packaging. It is also used to make aseptic packaging that enables the storage of perishable goods without refrigeration.

A Common application of Aluminum Foil

- Package

Aluminum is used in packaging because it has a high degree of ductility: it can easily convert into a sheet and fold, roll up or pack. Aluminum foil can completely block light and oxygen, odor and taste, humidity and bacteria. So it is widely used in food and drug packaging, including long-life packaging for beverages and dairy products No need to refrigerate, you can store them. Aluminum foil containers and trays are used for baking pie and packaging takeaway food, ready-to-eat snacks and pet food.

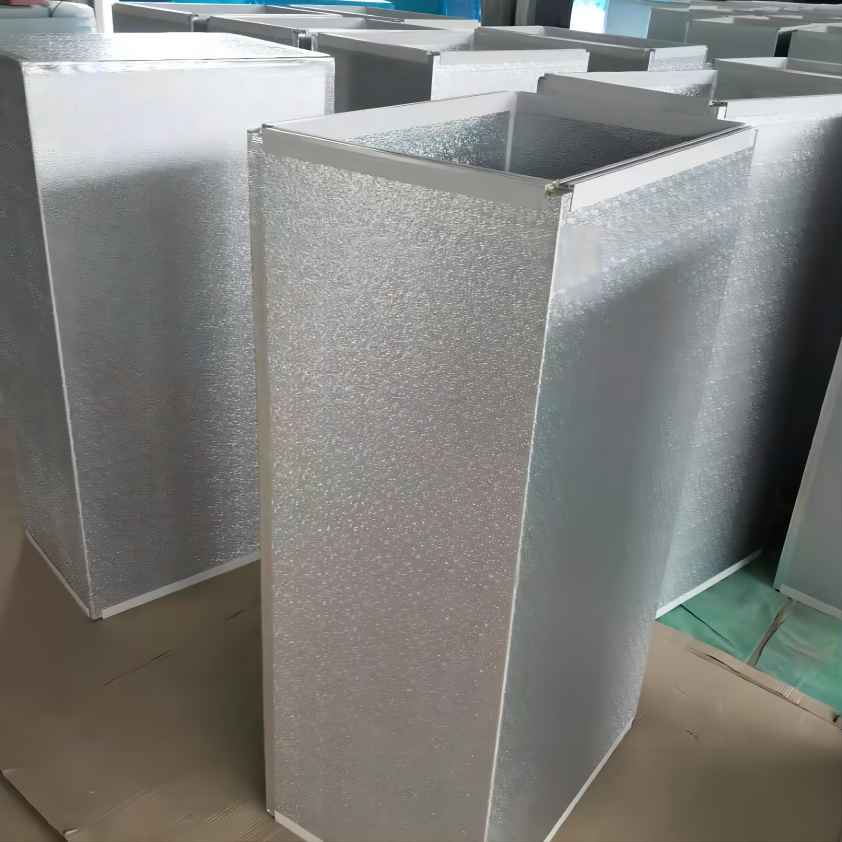

- Insulation

Aluminum materials have good insulation. The reflectance of the aluminum foil is 88%, which is widely used in heat insulation, heat exchange, and cable lining.

- Electronic product

The aluminium foil in the capacitor provides a compact storage for a charge. If the foil surface is treated, the oxide coating can be used as an insulator. Aluminum foil capacitors are common in electrical equipment, including televisions and computers.

- Ornaments

Heavy aluminum foil for art, decorative and crafts, especially bright metals. Metal aluminum, usually silver, can be treated into other colors by anodizing. The anodization forms a layer of oxide layer on the surface of the aluminum, which can receive a colored dye or metal salt, depending on the process used. In this way, aluminum is used to make an inexpensive gold foil, which actually does not contain gold and many other bright metals. These foils are sometimes used for unique packaging.

Some Questions About Aluminum Foil

Q: Cook health with aluminum foil?

A: In most cases, yes, you can sometimes don’t have to worry about cooking on the aluminum foil. A small amount of aluminum may be obtained by cooking, some form of aluminum-usually considered safe by FDA. However, you should avoid acidic foods on aluminum – such as any food in tomato as a substrate or with lemon.

Q: Is it polluted with aluminum foil?

A: Some aluminum foil products can be recovered around 5% of the original energy cost. Unless the aluminum laminate is difficult to separate the assembly or the aluminum metal production is low without recycling.

Q: What is the development prospect of aluminum foil?

A: Aluminum foil is increasingly combined with flexible films to make light packaging. This technique allows the packaging to expand during production, and then shrink with the consumption of the product. Only pet food, tuna, coffee and soup packaging produced 13 billion packages, can be replaced by flexible foil-based packaging. There are still many market applications of aluminum foil.

Q: Where can I find a reliable aluminum foil supplier?

A: There are many aluminum products suppliers around the world. Price and quality are also uneven. Chal Aluminium Corporation is a top aluminum foil supplier from China. Have rich product experience in aluminum products. We provide a targeted aluminum product solution for customers around the world. You can consult us with your business problem. Our engineers and salesperson will do our best to serve you.