How to Choose The Right Aluminum Strips?

Aluminum strips are a new type of environmentally friendly building material product made of high-purity aluminum, which has the characteristics of corrosion resistance. The aluminum strip is an essential material for…

What Is the Difference Between Aluminum Foil and Tin Foil?

Aluminum foil refers to paper made of aluminum foil backing paper and aluminum foil paper. It is often used to wrap food. Most of the tin foil we commonly use now…

How to Store Aluminum Coil Correctly?

As the use of aluminum coil becomes more and more popular, aluminum coil storage is very important for customers. Today, this article will introduce precautions for aluminum coil storage. Features…

Color-coated Aluminum Coils Types, Characteristics and Applications

Color-coated aluminum coils are the surface coating and coloring treatment of aluminum plates or aluminum coils. The commonly coated aluminum coils are fluorocarbon color-coated aluminum coils and polyester color-coated aluminum coils…

3 Things to Know about Aluminum T-slot Sytems in Buildings

As aluminum T-Slot Systems are popularly used in buildings, this article will introduce the applications of Aluminum extruded T-slot systems, the advantages of Aluminum extruded T-slot systems, and why choose 80/20 Aluminum T-slot…

What are the uses of aluminum foil in daily life?

Aluminum foil has begun to be fully used in our lives. It is used for packaging takeaway clay-pot rice, KFC egg tart trays, “tin foil ironing” when perming hair, medicine…

Why Are Bubbles on the Surface of Aluminum Profiles?

When the aluminum profile is extruded and pressurized, the air will remain in the aluminum profile, causing bubbles to appear inside and on the surface of the aluminum profile, causing…

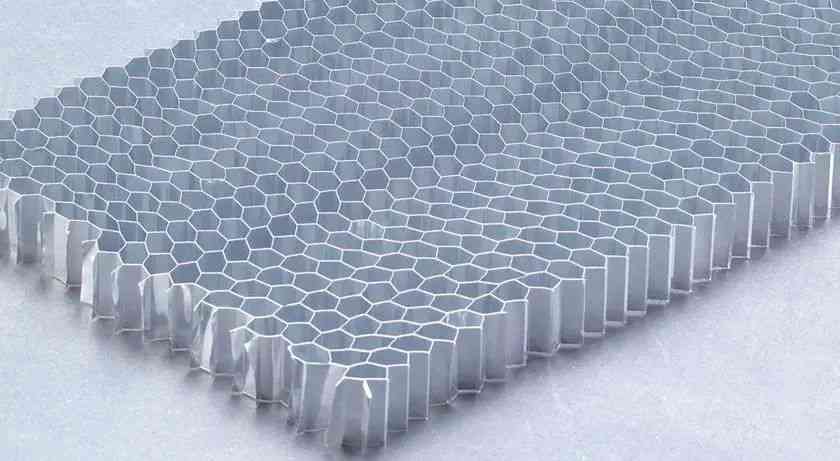

An Article to Understand Lithium Battery Aluminum Foil Quickly

With the rapidly growing demand of the lithium battery industry, lithium battery aluminum foil is used more and more popular. This article will introduce you to the battery aluminum foil…

11 Common Aluminum Foil Uses in Life

Aluminum foil is the sole metal foil used in flexible packaging. Aluminum foil uses on packaging has a long time. Aluminum foil is used as a packaging material, which cannot be…

3 Ways to Fix Aluminum Profiles to the Ground

Today, this article will share with you the fixing method of aluminum profiles. If you have any questions about the aluminum profiles that you buy from chaluminium, please leave a…

6063 Aluminum Tube – What do You Know?

As for the 6063 aluminum tube, what exactly does it refer to? Today, this article will introduce you to everything about the 6063 aluminum tube. What is the 6063 aluminum…

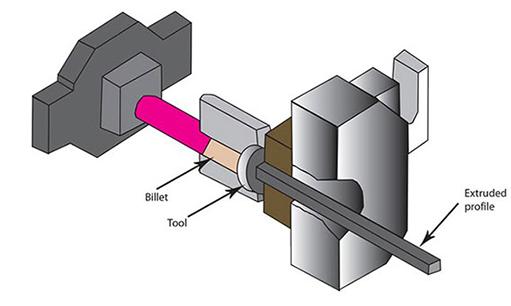

Extrusion Speed of Aluminum Profiles -Factors and Extrusion Processes

When metal is extruded, as the temperature rises, the non-uniformity of metal fluidity will increase. During the entire extrusion process, the temperature of the ingot in the deformation zone also…