Aluminum Pipes VS. Aluminum Tubes: They Are Not One Thing

Aluminum tubes and aluminum pipes are both names for aluminum hollow cylinders. Often, these words are used interchangeably. Both “aluminum tube” and “aluminum pipe” are long hollow cylinders. But engineers,…

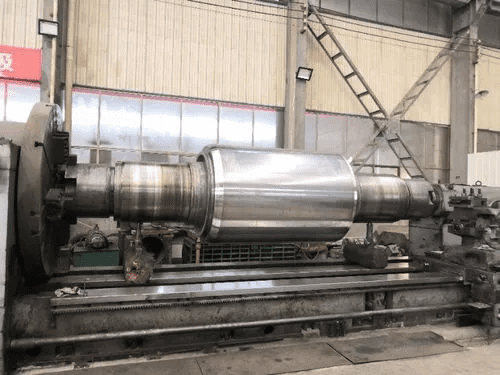

4 Common Causes of Bulges in High-Speed Aluminum Foil Rolling

Aluminum foil often encounters problems such as wrinkling, cross-layering, bulges, and poor shape during high-speed rolling. Any defect may cause the next pass to be scrapped, and the finished product rate…

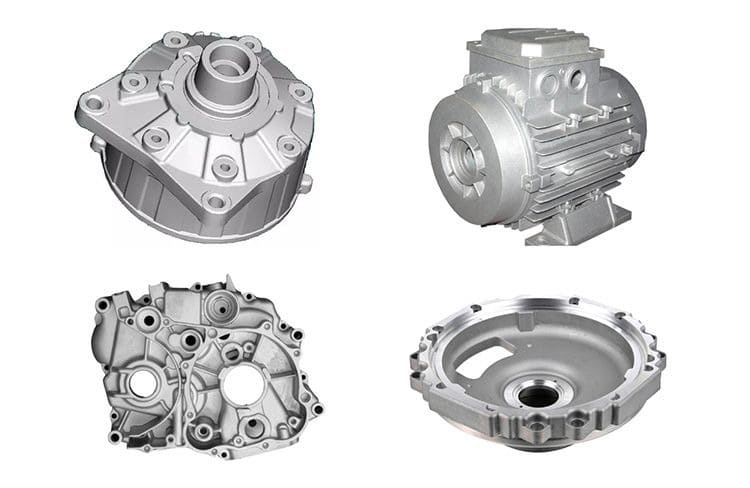

How to Anodize the Aluminum Die Casting Parts?

After the aluminum die casting parts are produced, to make them look better and increase corrosion resistance, it is generally necessary to anodize the aluminum die casting parts. This article will describe…

Fluorocarbon Aluminum Sheet VS Polyester Aluminum Sheet, Who is better?

We all know that there are many kinds of aluminum sheets on the market now. The aluminum panels generally used in walls are mainly fluorocarbon aluminum panels, which are also…

Why Your Aluminum Die Casting Parts Are Easily Damaged?

Aluminum die castings refer to equipment components made of pure aluminum or aluminum alloys obtained by casting. In general, heated liquid aluminum or aluminum alloy is poured into sand molds or…

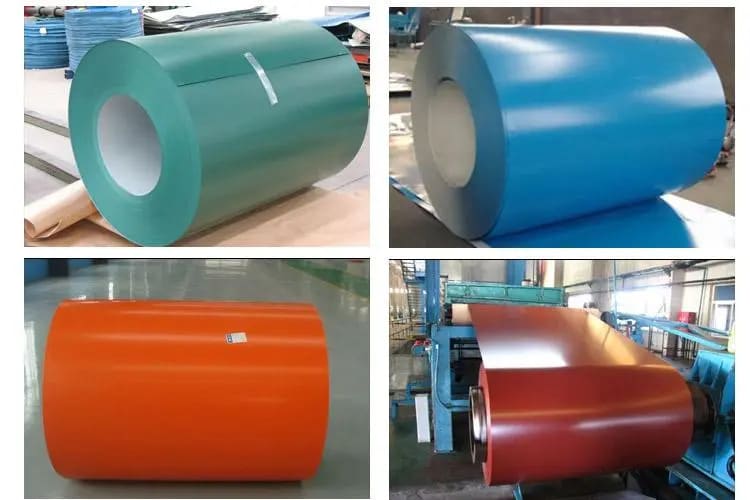

9 Different Applications of Aluminum Coil

The aluminum coil is a metal product that is subjected to flying shear after being rolled by a casting and rolling machine and processed by drawing and bending angles. Aluminum coils…

8 Elements Will Affect the Performance of Aluminum Coil

The eight major elements that affect the performance of aluminum alloys are metal elements such as vanadium, calcium, lead, tin, bismuth, antimony, beryllium, and sodium. Due to the different uses…

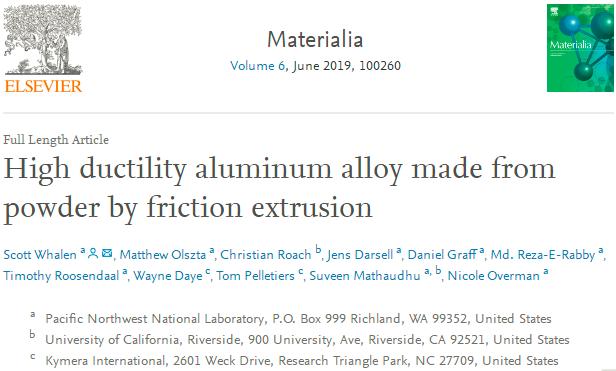

Aluminum alloy new process! Easily reduce processes and improve performance

Researchers at Pacific Northwest National Laboratory have recently demonstrated an advanced fabrication process that can produce nanostructured rods and tubes directly from high-performance aluminum alloy powders. Using a new solid-phase treatment…

4 Steps to Aluminum Foil Cleaning Your Silverware

Has your silver jewelry started to look dull after a long-standing period? Glossy silver has always been the number one source of favorite jewelry and fine tableware, but when it…

Why does the automotive industry love aluminum die casting?

Aluminium die casting is one such device that can aid in the delivery of elaborate components that can be used within damaging mechanism and for manufacturing other parts of different…

Copper Wire vs Aluminum Wire: Pros and Cons

Each metal material has its characteristics. As the most commonly used metals in power systems, copper wire, and aluminum wire have their uses and their advantages, and disadvantages. As an electrician,…

Advanced Methods To Improve The Quality Of Aluminum Alloy Ingots

As the demand for aluminum profiles in the world is more urgent, at the same time, all aspects of the properties of aluminum profiles, such as profile surface quality, surface treatment performance,…