Process Requirements for Welding and Coating of Aluminum Alloy

Stamping Parts The characteristics and performance advantages of aluminum alloy make it one of the preferred materials for lightweight vehicles today. The forming characteristics of aluminum alloy sheets and their…

Aluminum Alloy Extrusion Die And Extrusion Production Process

Aluminum and aluminum alloy profiles are widely used in construction, transportation, electronics, aerospace, and other sectors. In recent years, due to the demand for miniaturization and weight reduction of automobile air-conditioning…

5 Ways To Quickly Judge The Surface Quality Defects of Aluminum Profiles

In the process of aluminum profile production, it is often necessary to formulate a reasonable inspection frequency, which requires the selection of a reasonable judgment method according to the different…

5 Details About Aluminum Tread Plates

A tread plate is a form of metal stock with a regular pattern or lines on one side for slip resistance. It is also referred to as a checker plate…

What Defects are Prone to Occur in the Surface Treatment of Aluminum Profiles?

There are three common surface treatment methods for aluminum profiles: anodizing, electrophoretic coating, and powder coating. Anodizing is mainly used for the surface treatment of industrial profiles. Electrophoretic coating and…

What are the Main Points of Aluminum Extrusion Die Design?

To manufacture a good set of aluminum extrusion die, not only good processing equipment and skilled extrusion die manufacturing workers, but also a very important factor is to have a…

Is an All-aluminum Body 100% Aluminum?

What is an all-aluminum body? The whole aluminum body refers to the body structure mainly made of aluminum alloy. Not only does it allow some non-aluminum parts to existing, but…

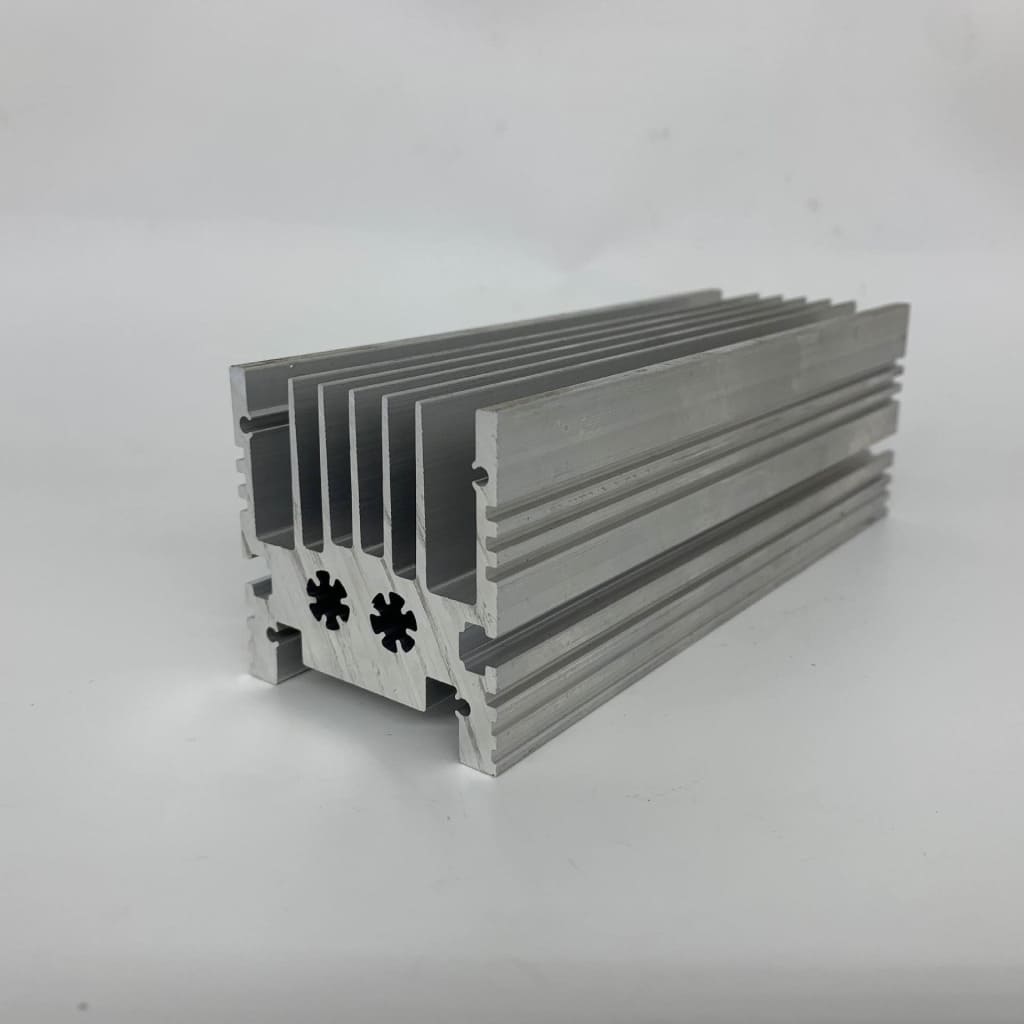

What Factors Should be Considered When Choosing Industrial Aluminum Profiles?

Standard aluminum profiles include architectural, decorative, and industrial aluminum profiles. All kinds of aluminum profiles have a variety of specifications and models. The industry’s most commonly used aluminum profiles are the 6063-T5…

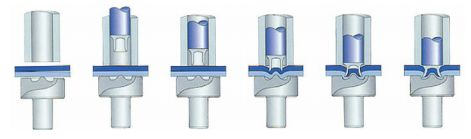

Cracks in Aluminum Alloy Welded Joints and Their Characteristics

When aluminum alloys are welded, some cracks often occur at the joints. This will affect the quality of aluminum tubes, aluminum profiles, etc. Therefore, this paper will conduct an in-depth…

What is the Difference Between Titanium Alloy and Aluminum Alloy?

What is Aluminum Alloy? Aluminum alloy is made of pure aluminum by adding some alloying elements, such as aluminum manganese alloy, aluminum copper alloy, aluminum-copper-magnesium series hard aluminum alloy, aluminum-zinc-magnesium-copper series super-hard…

5 Processes for Surface Treatment of Aluminum Profiles

With the gradual maturity of aluminum processing technology, some complex surface treatments of aluminum profiles have flourished. We often see the surface treatment processes of aluminum profiles include electrophoresis, anodizing, and…

Classification of Aluminum Corrosion

According to the usual estimation method, the direct economic loss caused by corrosion in China accounts for about 3% of GDP (gross national product) every year, and the steel consumed…