What is an all-aluminum body?

The whole aluminum body refers to the body structure mainly made of aluminum alloy. Not only does it allow some non-aluminum parts to existing, but also aluminum appears in the form of an alloy.

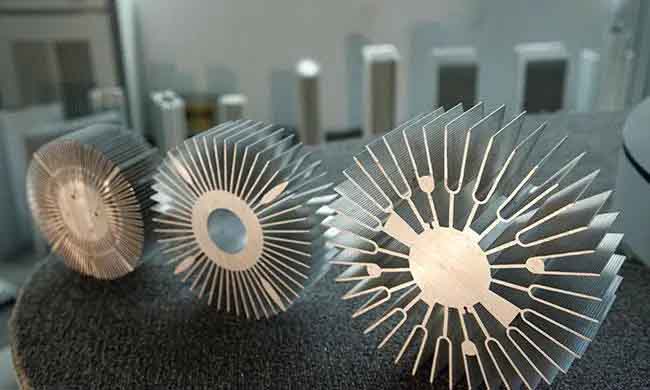

Aluminum alloy does not refer to an alloy. There are many categories. The international rule uses a four-digit number plus a letter to distinguish the type of aluminum alloy, such as the 6063-T5 aluminum heat sink commonly used in the construction industry. The first digit is 1 to represent pure aluminum with a purity higher than 99%, 2-8 represent alloys composed of aluminum and copper, manganese, silicon, magnesium, magnesium + silicon, zinc, and other elements, and 9 is the spare group. The following numbers are mainly used to distinguish, and the aluminum body will not repeat the specific logic. In short, each formula of aluminum alloy has a unique label corresponding to its unique characteristics. Currently, the 5 series and 6 series are mainly used in the all-aluminum body of automobiles, which are materials with low density, good tensile strength, and fatigue resistance. They can achieve higher power at a much lower weight than steel, including Audi ASF all-aluminum bodies and so on are widely used.

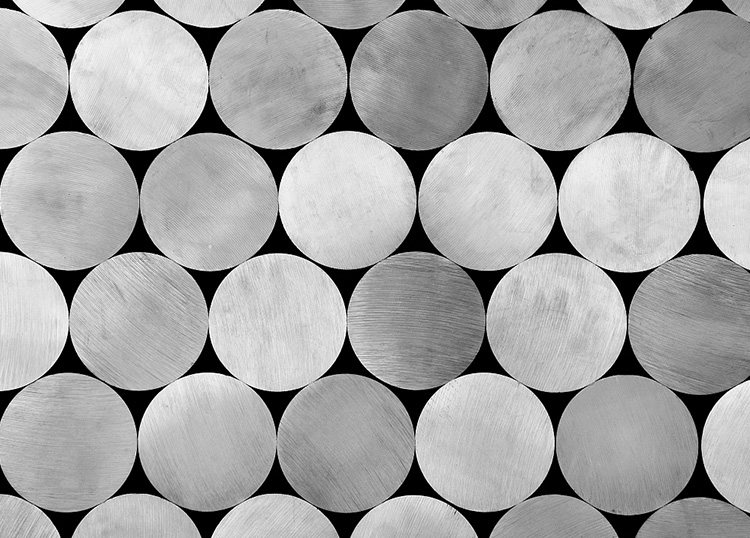

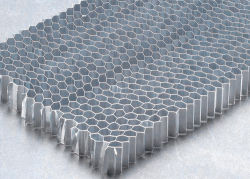

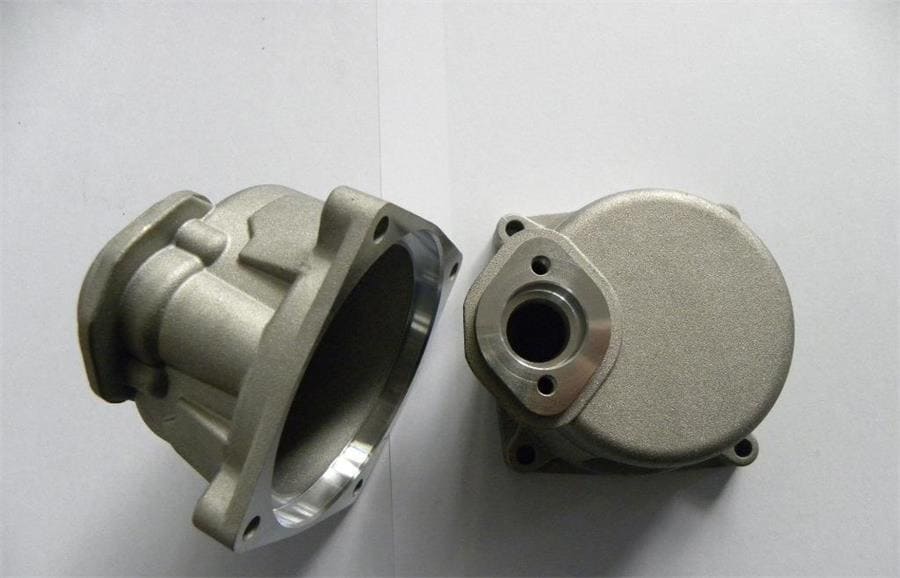

In addition, the two series and seven series also have a small number of applications. The two series copper alloy has high hardness and will be used in some body sheet metal parts; the 7 series is used primarily in the aviation and military fields, which are super hard, corrosion-resistant, and wear-resistant. Of course, the price is also very touching. At present, the domestic 7 series aluminum materials mainly rely on imports. Still, the ES8 body-in-white longitudinal beams released by Weilai some time ago use 7003 aluminum materials (as shown in the figure below). There are also some special aluminum castings (HPDC) that have many applications.

All aluminum is not equal to pure aluminum

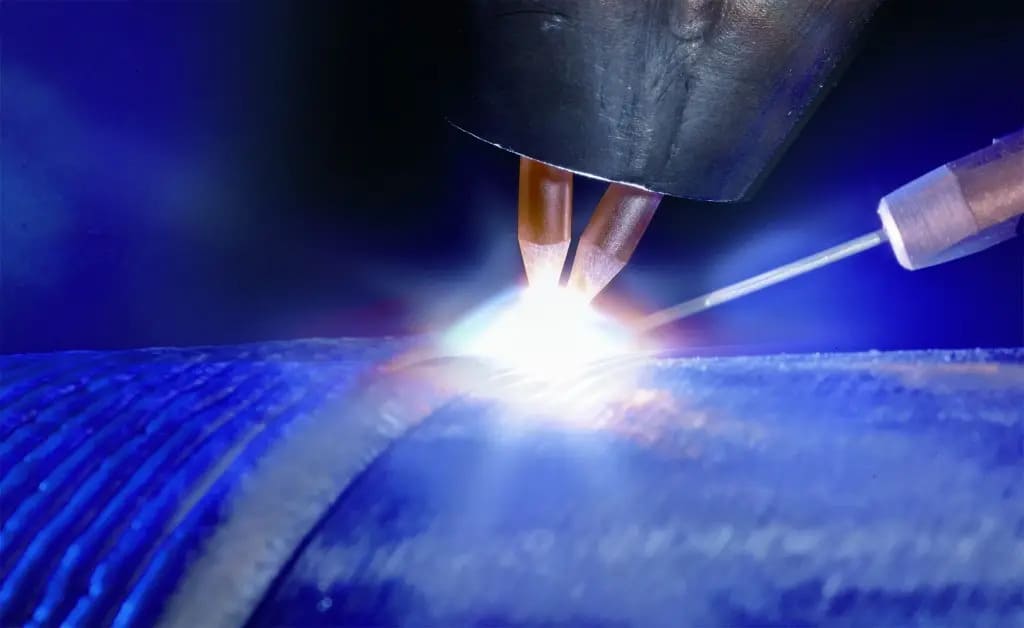

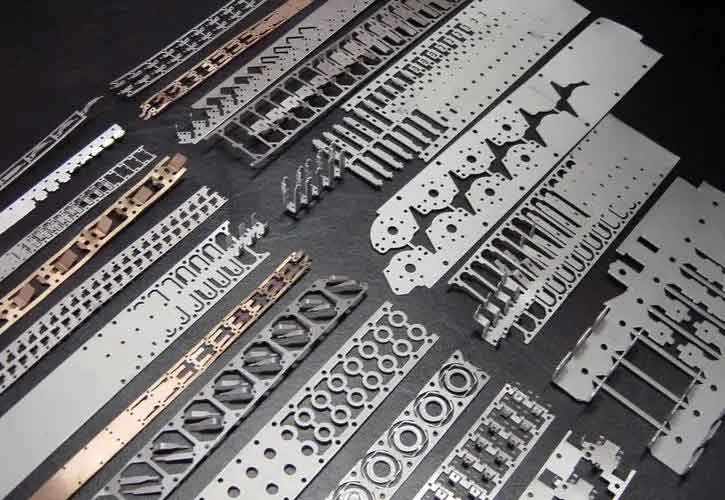

After clarifying these many misunderstandings, there will be no more, at least knowing that “all aluminum” does not mean “pure aluminum.” Different aluminum alloys have other characteristics, but the aluminum alloys used in the structural field have a common feature: high strength. Their hardness is generally more substantial than the exact specification of stainless steel. After coating and drying, the yield strength is above 200Mpa, and SPCC/DC04 is also 150-160Mpa. In addition, the all-aluminum body is not a whole. Aluminum alloys will distribute different materials according to the force of various body parts (the picture below is still NIO ES8, the distribution of aluminum alloys of other materials in the body-in-white), usually through self-piercing rivets and lasers. It is connected by welding, gluing, etc. The legend is invalid that the whole body will be scrapped after hitting professional tools that can replace the damaged parts. Of course, it is more expensive.

What are the advantages of an all-aluminum body?

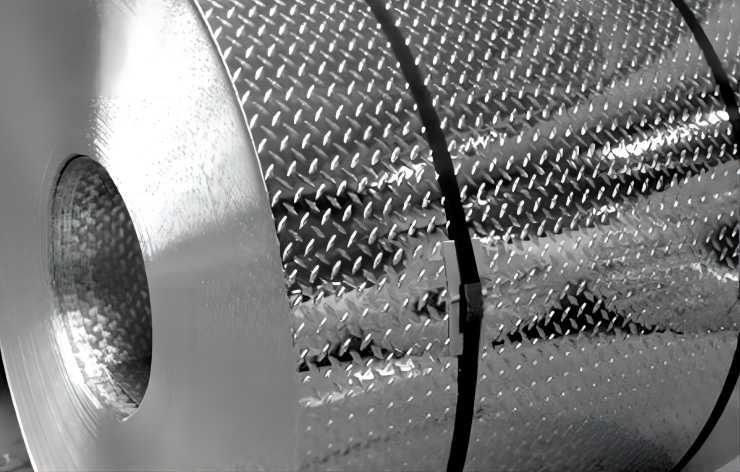

- Excellent lightweight effect. The density of steel is 7.8, while the thickness of aluminum is 2.7. In a traditional car, the body accounts for 30-40% of the whole vehicle’s weight. Using high-strength steel instead of ordinary steel can reduce the weight by about 11%, and if the aluminum alloy is used, the weight can be reduced—by about 40%. Aluminum alloy can be used in a vehicle with more than 500kg, and the effect is that the car’s weight can be reduced by about 40%.

- Improve body strength and increase safety. In terms of absolute power, aluminum alloys are slightly inferior to steel plates, but low density gives aluminum alloys more advantages. For steel plates and aluminum alloys of the same strength, the thickness ratio is 1:1.4, and the weight ratio is only 1:0.5; aluminum alloys have the Same power at half the weight. Generally, the aluminum alloy plate for an all-aluminum body is 0.2-0.5mm thicker than ordinary low-carbon steel. Increasing the thickness can achieve higher body rigidity and torsion resistance than high-strength steel.

- Improve maneuverability. This point is directly linked to the previous two issues. Lightweight can reduce the body’s inertia and increase the thrust-to-weight ratio, and an all-aluminum body can significantly improve the power performance under the same power level.

- Super corrosion resistance. Aluminum itself is not stable and is easy to oxidize. However, aluminum oxidation will form a dense oxidation layer on the surface and firmly combine with the substrate. The stability is highly capable of strict protection on the aluminum matrix.

Better plasticity. I can’t help but want to mention that aluminum alloy can create beautiful body surfaces, such as Jaguar C-Type.