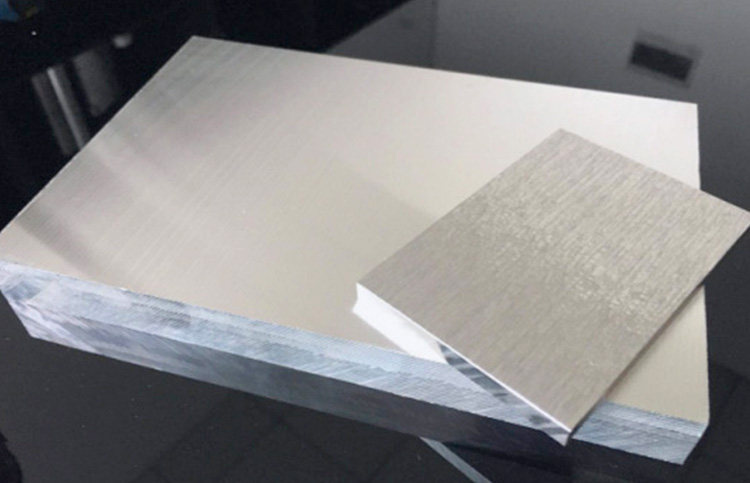

Aluminum 7075 T651 and 6061 T6 are two of the most common aluminum alloys. They are both strong, lightweight, and corrosion-resistant, making them ideal materials for a variety of applications. However, they have different properties, so the choice of which alloy to use will depend on the specific application.

What Are Aluminum 7075 T651 and Aluminum 6061 T6?

Aluminum 7075 T651 and aluminum 6061 T6 are both heat-treated aluminum alloys. They are both strong and machinable, but they have different properties.

Aluminum 7075 T651 is a high-strength alloy that is often used in aerospace applications. It has a high tensile strength and yield strength, making it very resistant to deformation. However, it is not as ductile as aluminum 6061 T6, meaning that it is more likely to crack under stress.

Aluminum 6061 T6 is a general-purpose alloy that is often used in automotive and marine applications. It is not as strong as aluminum 7075 T651, but it is more ductile. This makes it more resistant to cracking and easier to machine.

What Are the Similarities and Differences Between the Two Alloys?

The two alloys have a number of similarities. They are both heat-treated aluminum alloys, and they are both strong and machinable. However, they also have some important differences.

Aluminum 7075 T651 has a higher tensile strength and yield strength than aluminum 6061 T6. This means that it is more resistant to deformation. However, aluminum 6061 T6 is more ductile, meaning that it is more resistant to cracking and easier to machine.

Why Are They Important?

Both aluminum 7075 T651 and aluminum 6061 T6 are important alloys with a wide range of applications. Aluminum 7075 T651 is often used in aerospace applications because of its high strength. Aluminum 6061 T6 is a general-purpose alloy that is often used in automotive and marine applications.

Properties of Aluminum 7075 t651 and 6061 t6

Mechanical Properties

The mechanical properties of aluminum 7075 T651 and aluminum 6061 T6 are summarized in the table below.

|

Property |

Aluminum 7075 T651 |

Aluminum 6061 T6 |

|

Tensile strength |

70,000-80,000 psi |

35,000-45,000 psi |

|

Yield strength |

54,000-65,000 psi |

25,000-35,000 psi |

|

Hardness |

160-180 HB |

100-120 HB |

|

Ductility |

10-15% elongation |

20-25% elongation |

Physical Properties

The physical properties of aluminum 7075 T651 and aluminum 6061 T6 are summarized in the table below.

|

Property |

Aluminum 7075 T651 |

Aluminum 6061 T6 |

|

Melting point |

570 °C |

600 °C |

|

Specific gravity |

2.81 |

2.7 |

|

Electrical conductivity |

59% IACS |

61% IACS |

Chemical Properties

The chemical properties of aluminum 7075 T651 and aluminum 6061 T6 are summarized in the table below.

|

Property |

Aluminum 7075 T651 |

Aluminum 6061 T6 |

|

Corrosion resistance |

Good |

Good |

|

Oxidation resistance |

Good |

Good |

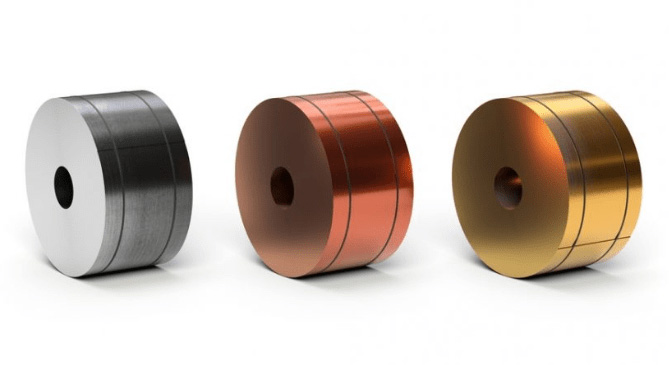

Applications of Aluminum 7075 T651 and 6061 T6

Aluminum 7075 T651 and aluminum 6061 T6 are used in a wide range of applications. Some of the most common applications include:

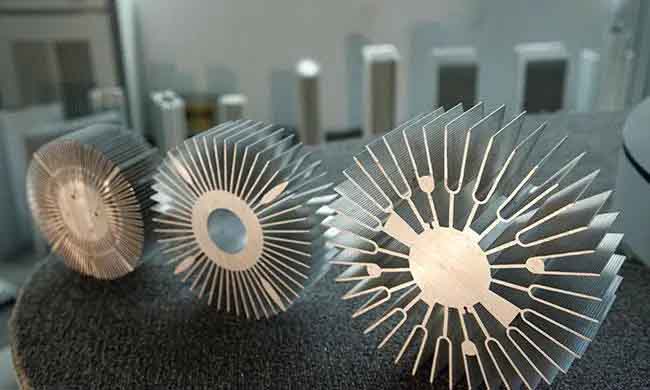

- Aerospace: Aluminum 7075 T651 is often used in aerospace applications because of its high strength. It is used in the construction of aircraft parts, such as landing gear, wings, and fuselage. It is also used in the construction of spacecraft, such as the International Space Station.

- Automotive: Aluminum 6061 T6 is a common alloy used in automotive applications. It is used in the construction of car parts, such as engine blocks, suspension components, and wheels. It is also used in the construction of boats and other marine vehicles.

- Marine: Aluminum 7075 T651 is often used in marine applications because of its high strength and corrosion resistance. It is used in the construction of ships, boats, and offshore structures. It is also used in the construction of underwater diving equipment.

- Construction: Aluminum 6061 T6 is a common alloy used in construction applications. It is used in the construction of buildings, bridges, and other structures. It is also used in the construction of furniture and other household items.

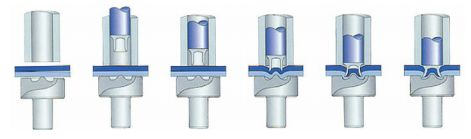

- Machinery: Aluminum 7075 T651 and aluminum 6061 T6 are both used in machinery applications. They are used in the construction of machine parts, such as gears, shafts, and bearings. They are also used in the construction of tools and other industrial equipment.

Conclusion

Aluminum 7075 T651 and aluminum 6061 T6 are both important aluminum alloys with a wide range of applications. They have different properties, so the choice of which alloy to use will depend on the specific application.

Aluminum 7075 T651 is a high-strength alloy that is often used in aerospace applications. It has a high tensile strength and yield strength, making it very resistant to deformation. However, it is not as ductile as aluminum 6061 T6, meaning that it is more likely to crack under stress.

Aluminum 6061 T6 is a general-purpose alloy that is often used in automotive and marine applications. It is not as strong as aluminum 7075 T651, but it is more ductile. This makes it more resistant to cracking and easier to machine.

The future of aluminum alloys is bright. As the demand for lightweight, strong, and corrosion-resistant materials continues to grow, aluminum alloys will become even more important. New developments in aluminum alloy technology are constantly being made, and these developments are opening up new applications for aluminum alloys.