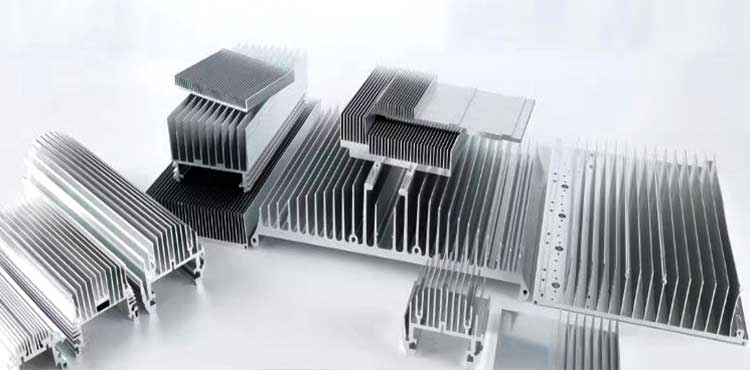

Why are aluminum heat sinks better than other materials’ heat sinks?

This guide is designed to give you a better understanding of what aluminum heatsinks do, how aluminium heat sinks differ from other materials, and why they work so efficiently. If you’re…

2 Main Factors Affecting Electrolytic Aluminum Coloring

What is Electrolytic Aluminum? Electrolytic aluminum is aluminum obtained by electrolysis. Modern electrolytic aluminum industrial production adopts the cryolite-alumina molten salt electrolysis method. Molten cryolite is the solvent, alumina is…

Why Choose Aluminum Plates As Home Improvement Building Materials?

In terms of home improvement building materials,Aluminum Plates are the most widely used metal ceilings. This is still inseparable from its advantages, but even if the aluminum plate has advantages,…

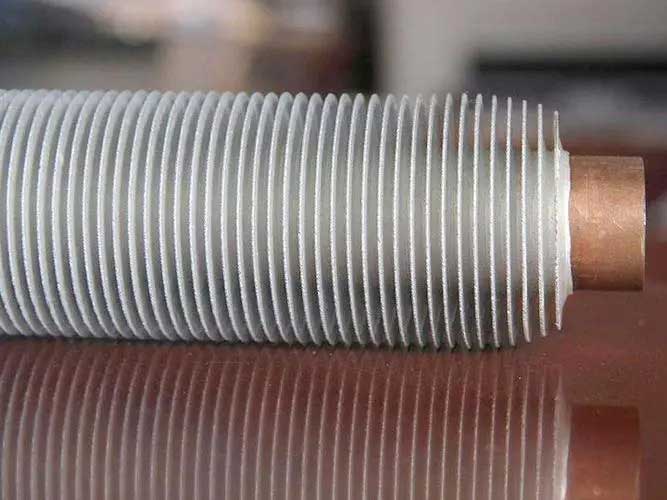

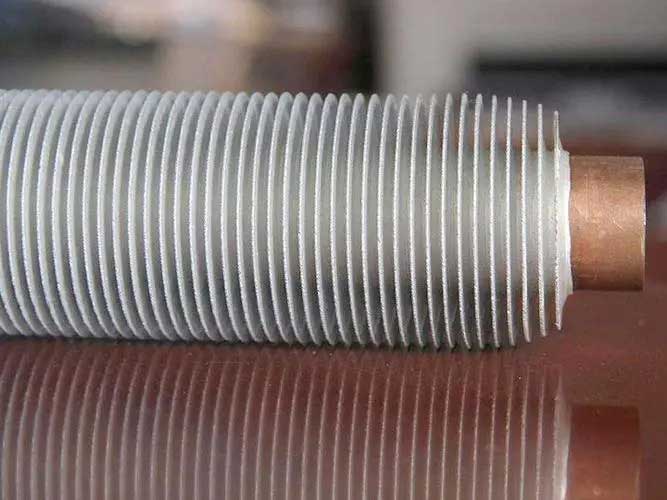

3 Most Important Tips About Finned Tubes

CHAL is a professional aluminum finned tube supplier, we often encounter some questions from customers about finned tubes. This article will answer the three most important questions and hopefully help…

The difference between extruded and die casting aluminum profiles

Many people cannot distinguish the process and application of extruded aluminum profiles and die casting aluminum profiles. This article will introduce the difference between these two processing methods through their respective advantages…

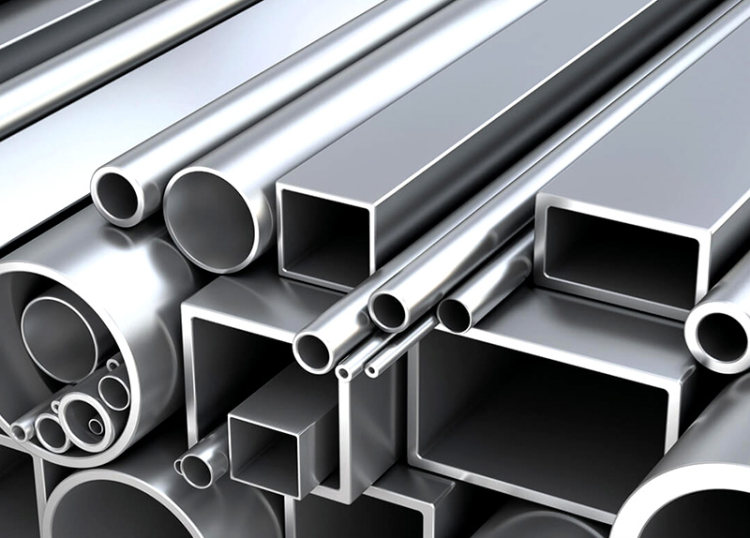

What is the Difference Between Seamless Aluminum Tube and Seamed Aluminum Tube?

Is it better to buy seamless or seamed aluminum tubes? Aluminum Tubes are widely used, especially in home appliances, but copper is also used in many home appliances. Relatively speaking,…

Why do Lithium Batteries Use Aluminum Foil for the Positive Electrode?

For lithium-ion batteries, the commonly used positive current collector is aluminum foil, and the negative electrode current collector is copper foil. In order to ensure the stability of the current…

5 Tips You Should Know About Finned Aluminum Tube

Aluminum finned tubes are a kind of aluminum processing parts that are often seen in our lives, such as air conditioners and air conditioners. So what exactly are finned tubes?…

Difference between seamless aluminum tube and extruded aluminum tube

Both extruded aluminum tubes and seamless aluminum tubes are high-quality aluminum machining parts. They have a similar appearance, so people are often unable to tell them apart. So what is stretched…

6 Properties of Aluminum Cable Wire

Aluminum cable wire makes up for the shortcomings of pure aluminium cables in the past, and improves the electrical conductivity, bending performance, creep resistance and corrosion resistance of cables, etc., which…

Do You Really Know About Aluminum Wire?

Aluminum wire is a wire that is used for electrical wiring in houses, power grids and airplanes. When compared to copper wire, aluminum wire is a more affordable solution considering its…

Carbon Fiber vs Aluminum

Aluminum materials have always been the most common and widely used materials in industrial materials. After updating according to conventional aluminum sheets, aluminum tubes, and other aluminium materials, more aluminum…