Cracks in Aluminum Alloy Welded Joints and Their Characteristics

When aluminum alloys are welded, some cracks often occur at the joints. This will affect the quality of aluminum tubes, aluminum profiles, etc. Therefore, this paper will conduct an in-depth…

What is the Difference Between Titanium Alloy and Aluminum Alloy?

What is Aluminum Alloy? Aluminum alloy is made of pure aluminum by adding some alloying elements, such as aluminum manganese alloy, aluminum copper alloy, aluminum-copper-magnesium series hard aluminum alloy, aluminum-zinc-magnesium-copper series super-hard…

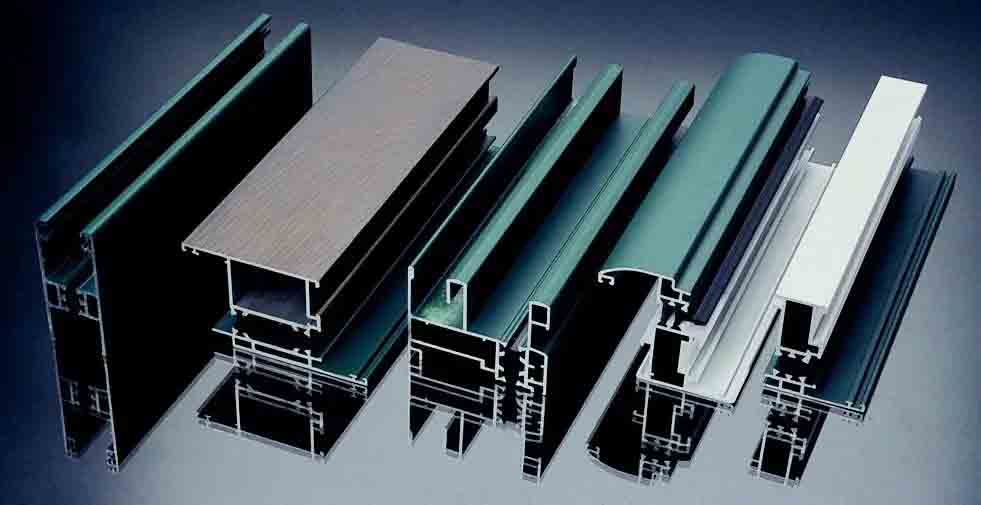

5 Processes for Surface Treatment of Aluminum Profiles

With the gradual maturity of aluminum processing technology, some complex surface treatments of aluminum profiles have flourished. We often see the surface treatment processes of aluminum profiles include electrophoresis, anodizing, and…

Classification of Aluminum Corrosion

According to the usual estimation method, the direct economic loss caused by corrosion in China accounts for about 3% of GDP (gross national product) every year, and the steel consumed…

Intergranular Corrosion of 6000 Series Alloys

Among the wrought aluminum alloys used today, the most widely used is the 6000 series alloys that can be strengthened by heat treatment, which are a class of Al-Mg-Si and…

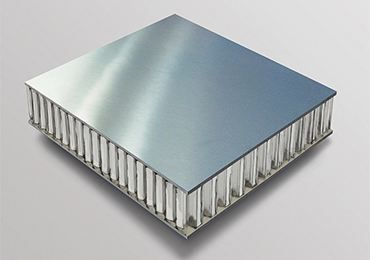

Aluminum Honeycomb Panel vs Aluminum Composite Panel: Applications and Characteristics

Introduction The decorative materials of the architectural metal curtain walls are the main products of today’s architectural curtain walls, including aluminum veneer, aluminum plate, and aluminum honeycomb panel. Among these…

Comparison between Aluminum Foil and Tin Foil

Aluminum foil refers to the paper made of aluminum foil backing paper and aluminum foil pasting. It is often used to wrap food. Most of the tin foil paper we…

Why is Annealing Treatment Required in the Processing of Aluminum Profiles?

Aluminum profile processing annealing is divided into aluminum plate, aluminum strip annealing, and aluminum foil annealing. The purpose of annealing is to eliminate the cold work hardening of continuous rolling or…

In the Air-conditioning Industry, “Aluminum will Eventually Replace Copper”

With the continuous expansion of the application range of aluminum, the development of the industry is facing new opportunities. Aluminum used in the air-conditioning industry is one of the important…

Copper Tube VS Aluminum Tube: Which is Better in Air Conditioner?

We all know that an air conditioner is an essential part of an air conditioner. The prices of different types of air conditioners vary greatly, but together with one brand,…

Why will the sales of aluminum foil food containers increase by 200% in China in 2022?

According to a report by the Aluminum Association of China, sales of aluminum foil food containers in China will increase by 200% in 2022. Does this herald new opportunities for aluminum…

What is the Effect of Different Anodization Degrees on Aluminum Electrolysis?

The prebaked anode is the most critical part of the electrolytic processing of aluminum, and it plays an important role in the electrolysis of aluminum. In this paper, the influence…