3 Things You Must Know About Aluminum Foil Tape

As a derivative of aluminum foil, aluminum foil tape is often used in our daily life and the production of factories. As one of the most common adhesion tools, this…

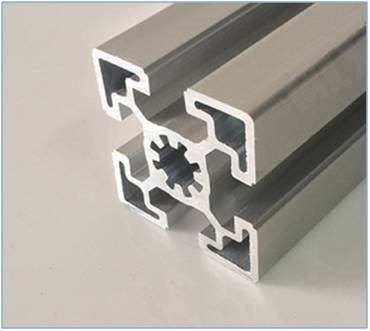

Aluminum Alloy Profile Extrusion – How To Ensure The Quality?

As a multi-purpose building material, aluminum profile is a sustainable non-ferrous metal with “green” environmental protection characteristics due to its good performance, easy processing, recyclability, lightness, corrosion resistance, and irreplaceable advantages…

Properties and applications of aluminum profiles

Aluminum profiles are new products formed from aluminum billets. Aluminum profiles meet the material needs of various fields through different forms. Aluminium profile is different from steel, it is a…

How to Properly Process Aluminum Profiles?

In the market, the conventional production method for the manufacture of aluminum profiles is the extrusion of aluminum ingots. However, aluminum profile manufacturers often cause product defects due to the…

What You Must Know Before Buying Aluminium Circle!

Aluminium circle is also known as aluminum disc, which is a perfect material for making aluminum round metal. Like aluminum plates, aluminum circles are processed aluminum materials made of aluminum…

What is the difference between aluminum plate 5052 VS 6061?

In the machining industry, there are many types of plates with different alloy numbers. For example, the alloy grades of aluminum plates are 5052 and 6061. These two specifications of…

What are the application areas of high-end aluminum alloy materials?

According to statistics, among the 124 existing industries in China, 113 are related to aluminum profile. “Replace steel with aluminum, save wood with aluminum, save copper with aluminum, and replace…

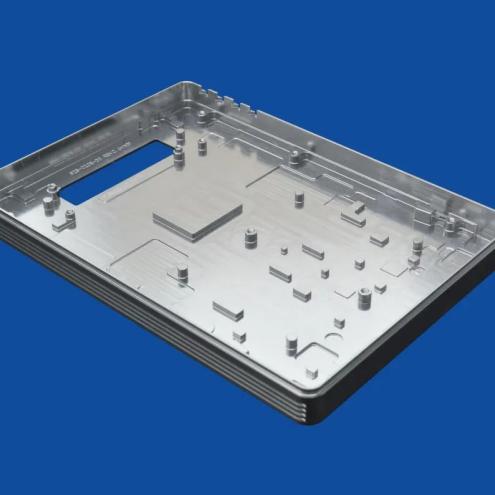

Realization Of 6063 Aluminum Sheet Rapid Extrusion Process

6063 aluminum alloy sheet is the most commonly used in aluminum sheet extrusion, and also the most widely used and most used deformed aluminum alloy in extruding building profiles and industrial profiles…

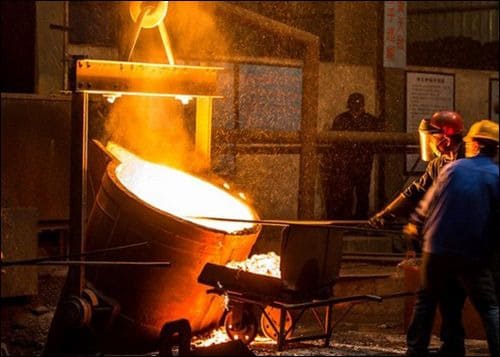

How to Reduce the Casting Consumption of Aluminum & Aluminum Alloy?

Aluminum and aluminum alloys are turned into finished aluminum products and semi-finished products by melting and casting. In the process of melting and casting, various degrees of loss will occur due to…

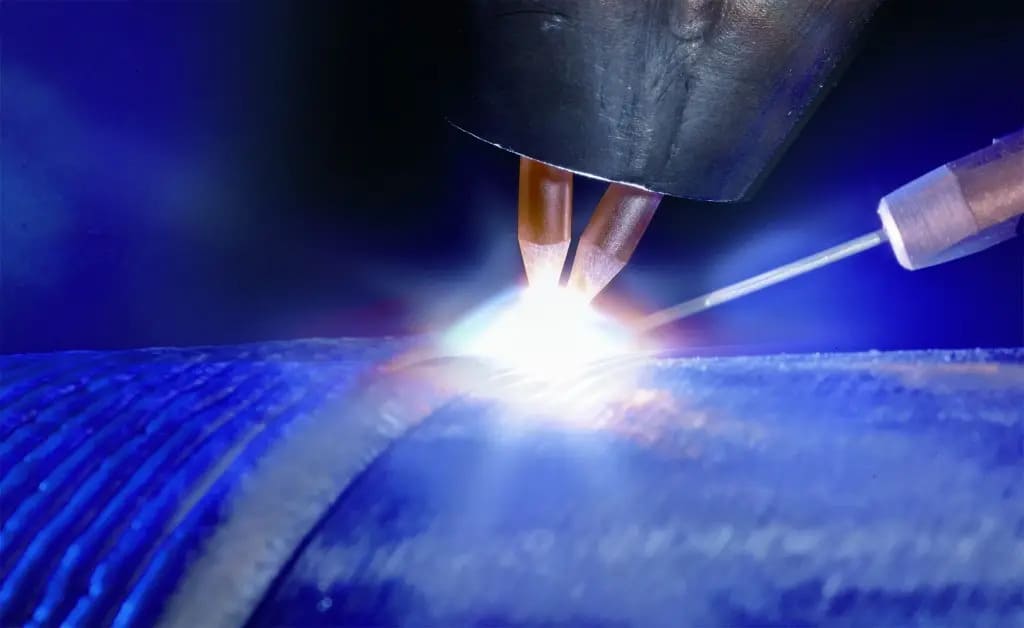

What Materials Are Commonly Used For Welding Aluminum Alloys?

With the rapid development of the aluminum alloy welding industry at this stage, the types of welding materials are gradually enriched. The following are some common welding materials. Requirements for…

How to correct the angle of the plane of the aluminum plate?

Aluminum alloy plate is a kind of industrial building material. It is used in various industries according to different materials. According to the surface treatment method, it can be divided…

Everything You Need To Know About Aluminum Alloy Gas Welding

Oxyacetylene welding commonly referred to as gas welding, is a process that relies on the combustion of oxygen and acetylene. The thermal efficiency of oxyacetylene welding is low, the welding…