What to Do for Aluminum and Aluminum Alloy Welding?

Aluminum is the most used metal material in the world. It is used in various fields such as construction, mechanical equipment, die casting, and bodybuilding. For the processing of aluminum,…

A Few Quick Tips to Choose Aluminum Profiles

Aluminum extrusions are very useful to both residential and commercial property owners. It is increasingly favored by people because of its strong versatility, long service life, convenient assembly and disassembly,…

What Is Important for You Processing Aluminum Machining Parts?

Aluminum is an absolute staple in any machine shop. It is one of the most machinable metals out there, so it can be machined quickly and efficiently. That’s why it’s…

Aluminum Tube Welding – Everything You Should Know

Almost all welding methods can be used to weld the aluminum tube and weld the aluminum alloy. Today, this article will introduce everything about aluminum tube welding. Basic Knowledge of…

What is the Best Aluminum Tube in 2023?

As a kind of non-ferrous metal tube, an aluminum tube is made of pure aluminum or aluminum alloy through extrusion processing to form a hollow metal tubular material along its…

6 Things You Should Know About Aluminum Extrusions

Aluminum extrusions (Aluminum profiles) are the construction industry’s most widely used aluminum processing products. We can find aluminum profiles in all doors, windows, and frames. Its advantages include but are not limited…

Copper Coil vs Aluminium Coil in Air Conditioners: Which is better

Cool, pleasant air is only a switch away during the scorching summer heat. Simply turn on the air conditioner and you’ll be surrounded by cool air in minutes. Aside from…

Copper Wire vs. Aluminum Wire: Which Is Better?

The wire and cable industry uses a variety of metal conductors, but the two most common are copper wire and aluminum wire. Because each metal type has unique properties, they are…

Everything You Need to Know About T-slot Aluminum

Lightweight aluminum is commonly utilized in the manufacturing of nearly any kind of product. But, before the product comes to life, there are particular phases where sub-parts of items are…

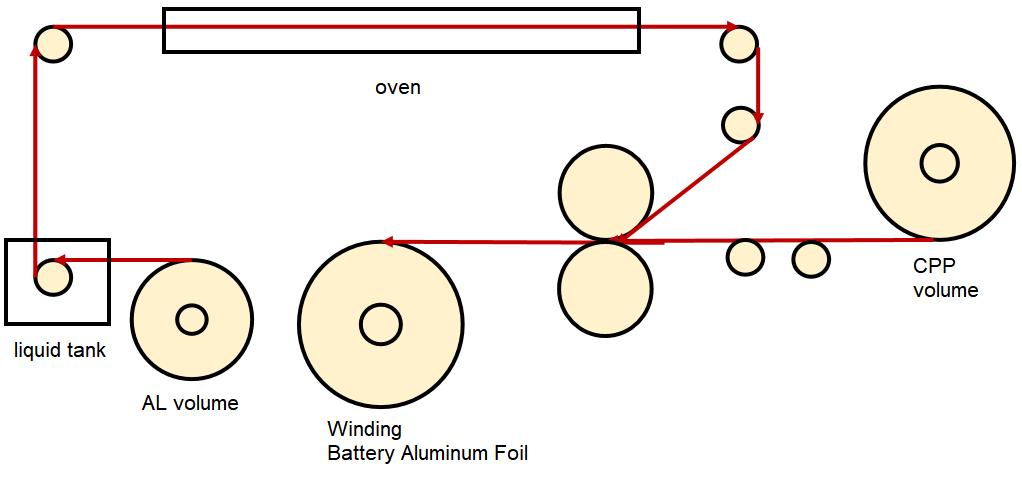

Learn the production process of lithium battery aluminum foil in 5 minutes!

According to the Power Battery Application Branch, at present, the demand for the aluminum-plastic film for power soft-pack batteries is accelerating. In 2020, the demand for China’s battery aluminum foil…

An Article to Know Aluminum Foil

Aluminum foil is a lightweight metal-based material produced in very thin thicknesses that can be easily formed for cooking, wrapping, covering, or lining processes when preparing or storing foods. It is a…

Aluminum Alloy For Metal Stamping

Metal stamping is a metalworking process that forms various parts and products from sheet metal. It accommodates a wide range of materials, including aluminum, stainless steel, low-carbon steel, copper and…