Aluminum extrusions (Aluminum profiles) are the construction industry’s most widely used aluminum processing products. We can find aluminum profiles in all doors, windows, and frames. Its advantages include but are not limited to lightweight and high corrosion resistance.

What new products are there for aluminum profiles in 2023, and will aluminum extrusions still be the first choice for high-quality building materials? This article will reveal the answer for you.

What are aluminum extrusions?

The aluminum extrusion is an alloy material with aluminum as the main component. Aluminum rods are melted and extruded to obtain aluminum materials with different cross-sectional shapes. However, due to the different proportions of the added alloys, the mechanical properties and application fields of the produced industrial aluminum profiles are also different.

Definition of aluminum extrusion processing: the process of extruding aluminum cast rods through an extrusion machine and forming a mold. Of course, aluminum profile processing also includes subsequent artificial aging, surface treatment, deep processing, and other processes. That is to say, aluminum processing includes the processing of aluminum profiles. Aluminum processing is the general term for aluminum alloy processing, while aluminum profile processing is a subdivided category.

What is the use of aluminum extrusions?

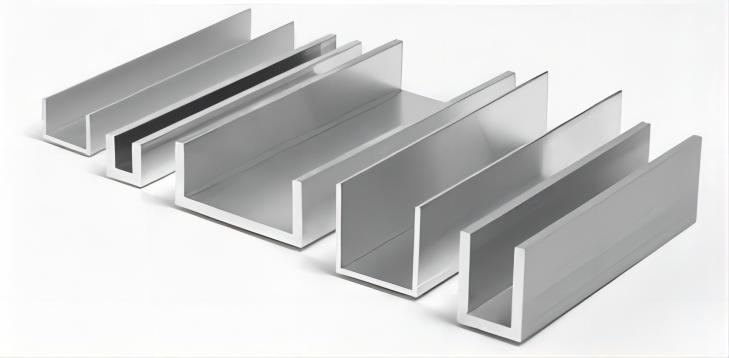

Aluminum extrusions are very commonly used in the manufacture of window and door systems and can be found in thousands of applications in construction and manufacturing. ATC’s most popular extrusions are the angled extrusions we stock in plain satin, pre-anodized, and pre-powder coated, black and white. These shapes are a simple right angle that can have sides of equal or unequal length and come in a variety of wall thicknesses.

Other popular aluminum profiles include shapes such as square hollow (or square tube), round tube, and rectangular hollow. We also supply solid profiles such as square, round and flat bars. ATC produces custom shapes for many of our customers. Keep in mind, though, that aluminum extrusion should be considered a batch process and requires at least a 250kg billet, as new dies can cost anywhere from $500 to $3,000.

How are aluminum extrusions processed?

Most aluminum profiles are processed by extrusion. Its forming method can be divided into the cold extrusion and hot extrusion. Most of the aluminum profiles we usually see are hot-extruded aluminum profiles. Relatively speaking, the hot-extrusion process is simpler and the technical content is not high. Therefore, the price of hot extruded aluminum profiles is not very high.

The cold-extruded aluminum profile is different. The cold-extruded process is complicated, the technical content is relatively high, and the equipment requirements are also high, so the price of the cold-extruded aluminum profile is relatively high. Cold-extruded aluminum profiles are only used in special areas. For example, seamless pipes can only be drawn by cold drawing.

Aluminum extrusions surface treatment process

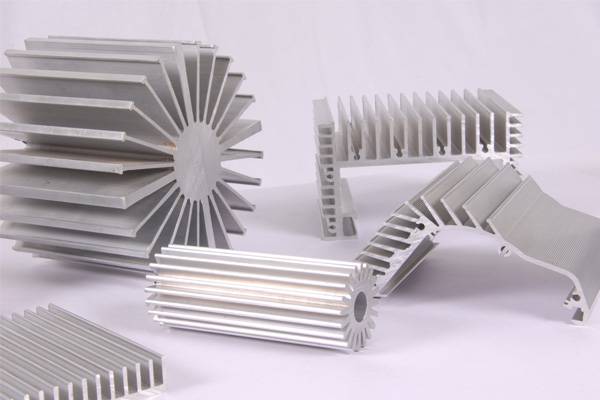

The above is the processing method of aluminum profile forming, and there are more processing methods of surface treatment. The common ones are anodizing, electrophoresis, spraying, wood grain transfer printing, etc. The matte effect of the sand surface can be achieved by various methods such as acid sand, alkali sand, and physical sandblasting. Anodizing and sandblasting are common surface treatment methods on industrial aluminum profiles. Spraying and wood grain transfer printing are commonly used surface treatment methods on architectural aluminum profiles.

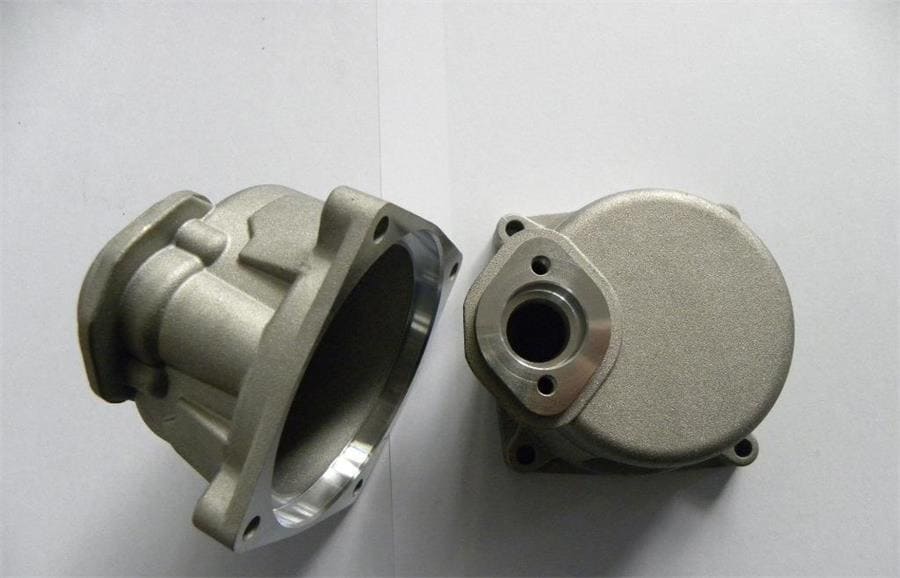

Aluminum extrusions deep processing technology

Generally, industrial aluminum profiles need more deep processing and are generally used for equipment accessories, supports, and so on. Processing methods include milling, cutting, drilling, tapping, stamping, etc. Deep processing equipment includes drilling machines, milling machines, punching machines, etc., as well as CNC machine tools, commonly known as “machining centers”. Because the aluminum profile processing center needs to process long materials, it adopts vertical processing, which can process 6-meter-long materials.

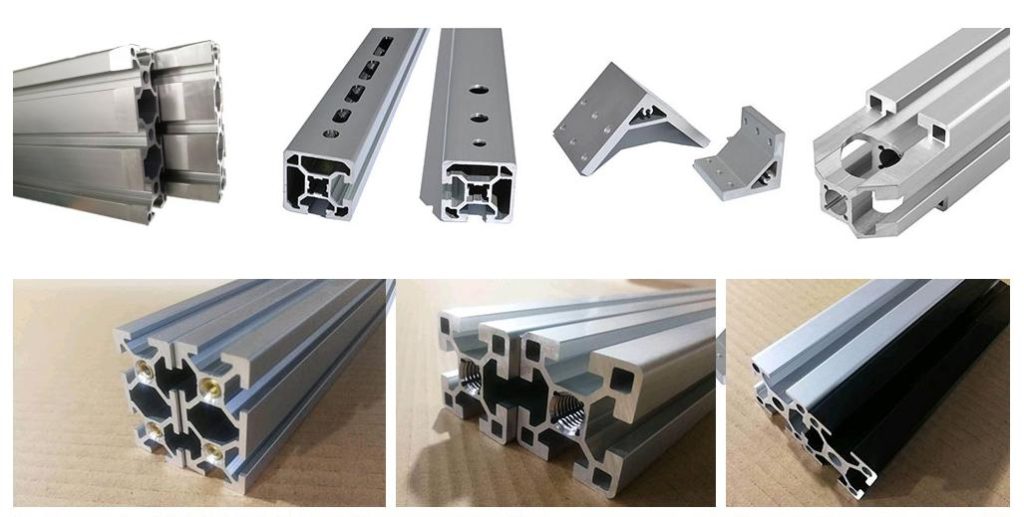

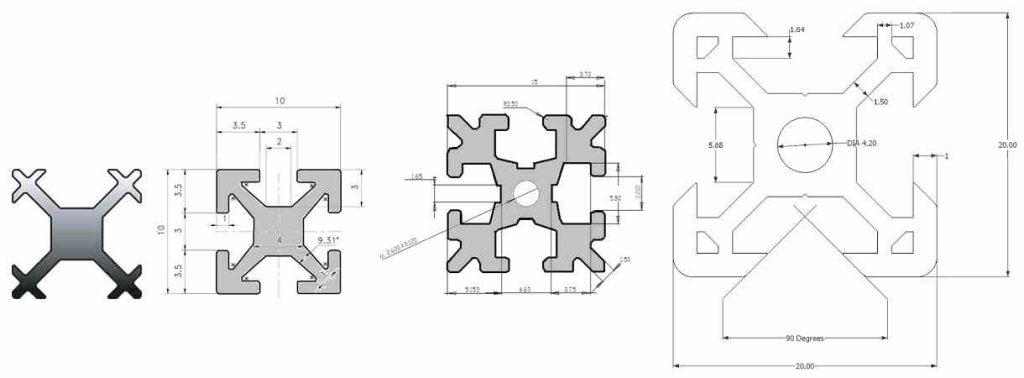

Typical products of aluminum extrusions -T-Slot Aluminum

Slot Aluminum is an unofficial standard for framing systems that consist of square or rectangular extruded aluminum lengths. They have a ‘T’ shaped slot along at least one of their sides.

These slots allow you to connect a wide range of hardware to the extrusion and adjust it as needed. They allow for an unprecedented level of customization and versatility for the designs and applications you can create.

These profiles can have no slots, a single slot, or multiple slots on each side. The size of the cross-section is also available in a variety of sizes.

You can easily set up frames and structures made from T-slots by joining the profiles with connectors, eliminating the need to weld components to get a robust construction.

While there is no single unified standard for the manufacturing of these extrusions, there are some guidelines on the most popular profile sizes and slot shapes. It is easy to identify which components and profiles are compatible.

Types of T-Slot Aluminum

There are many types of T-Slot Aluminum available on the market. Some of the most common for small-scale engineering include:

- V-Slot

- MakerBeam

- OpenBeam

- MicoRax

As shown above, these 4 type ranges from 10mm to 20mm square profile. Each profile has its unique features, but all share the “T” slot function.

Summary

Aluminum extrusions are one of the most common methods of creating strong, versatile, lightweight, strong and cost-effective frames and structures. Consider aluminum extrusions as an option the next time you design an equipment frame or structure.