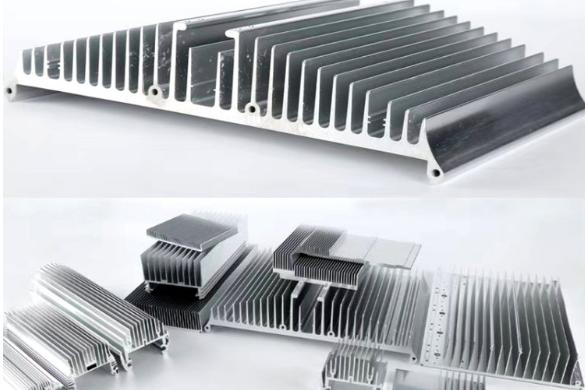

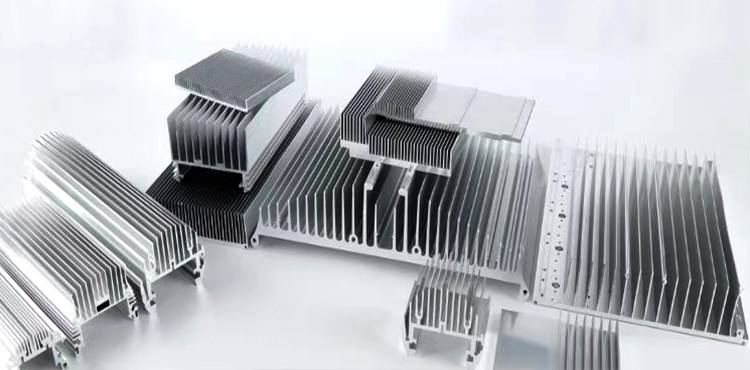

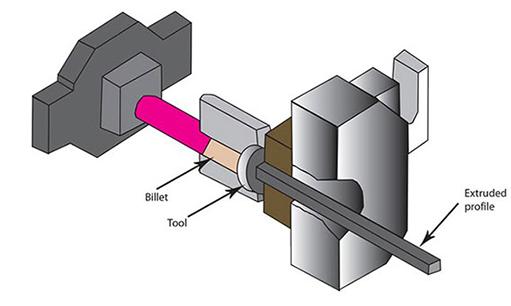

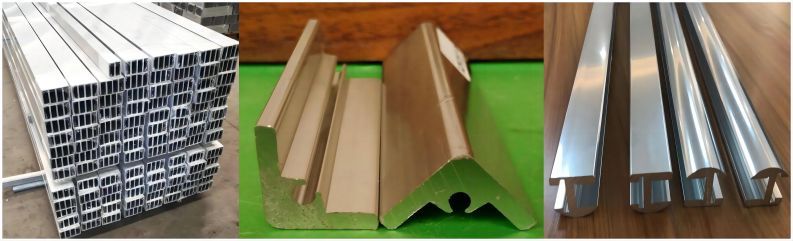

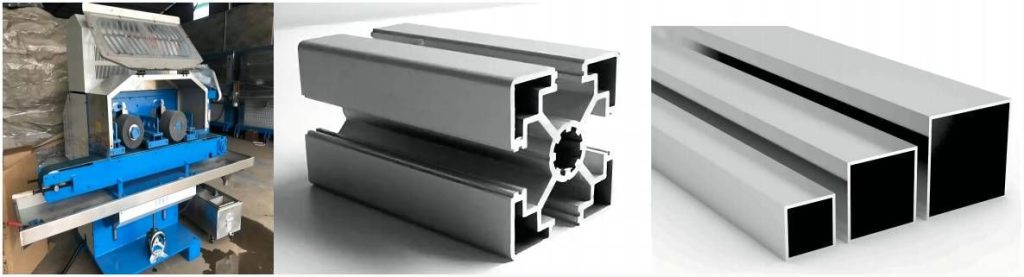

Aluminum profiles are widely used in various industries due to their exceptional properties such as durability, lightweight, and versatility. They are commonly used in construction, transportation, and manufacturing, and come in various sizes and shapes. Customization of aluminum profiles is essential to tailor them to the specific needs of different applications. One of the most common types of customization is surface finishing, which involves adding a layer to the aluminum profile to enhance its performance, appearance, and resistance to corrosion and other environmental factors. So, we’ll discuss the benefits of surface finishing customization, different types of surface finishing, factors to consider for customization, and advantages of partnering with a surface finishing specialist.

Benefits of Aluminum Surface Finishing Customization

Surface finishing customization of aluminum profiles offers several benefits that make it a worthwhile investment for different industries. Some of the benefits include:

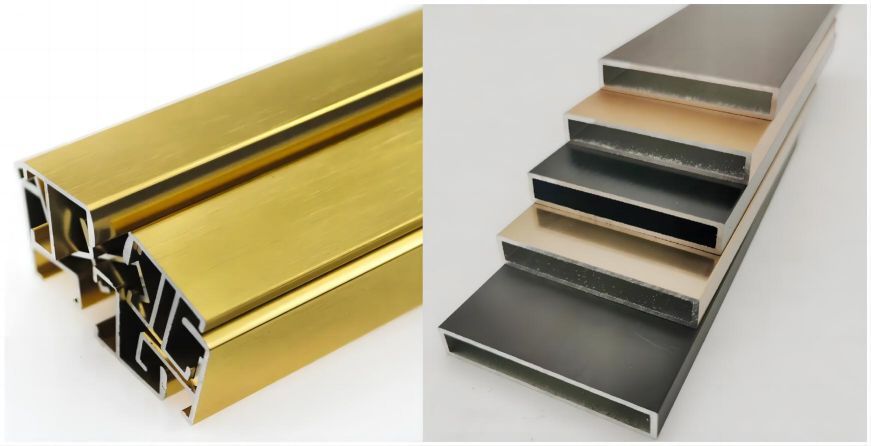

- Enhanced Aesthetics: Surface finishing can enhance the appearance of aluminum profiles, making them more appealing to the eyes. Different surface finishing techniques can be used to achieve different colors, textures, and finishes, depending on the intended use and design.

- Improved Corrosion Resistance: Aluminum profiles are prone to corrosion, such as 6061 aluminum channel, especially when exposed to harsh environments such as moisture and chemicals. Surface finishing can help protect the aluminum profile from corrosion, increasing its lifespan and reducing the need for maintenance and replacement.

- Durability and Wear Resistance: Surface finishing can make the aluminum profile more durable and resistant to wear and tear, especially when used in applications that require frequent handling or exposure to friction.

- Protection against Environmental Factors: Different surface finishing techniques can be used to provide protection against different environmental factors such as UV rays, temperature changes, and humidity, among others.

4 Types of Aluminum Surface Finishing

There are 4 different types of aluminum surface finishing techniques that can be used to customize aluminum profiles. Each technique has its unique benefits and drawbacks, and the choice of the best technique depends on the intended use and design. The following are some of the most common surface finishing techniques used for aluminum profiles:

- Powder Coating: Powder coating involves the application of dry powder to the aluminum extrusion profile, which is then heated to create a hard and durable finish. Powder coating is cost-effective, environmentally friendly, and offers excellent corrosion resistance and durability. It is also available in a wide range of colors and textures, making it suitable for different design applications.

- Anodizing: Anodizing involves the immersion of the aluminum profile in an electrolyte solution and passing an electric current through it to create an oxide layer on the surface. Anodizing offers excellent corrosion resistance, durability, and wear resistance, and can be used to achieve different colors and finishes.

- Painting: Painting involves the application of wet paint to the aluminum profile, which is then dried or cured to create a finish. Painting offers a wide range of color options and can be used to achieve different finishes such as matte, gloss, or semi-gloss. It is also easy to touch up and repair, making it suitable for applications that require frequent maintenance.

- Electrophoretic Coating: Electrophoretic coating involves the immersion of the aluminum profile in a paint solution and passing an electric current through it to create a coating. Electrophoretic coating offers excellent corrosion resistance, durability, and wear resistance, and can be used to achieve different colors and finishes.

4 Factors to Consider for Surface Finishing Customization

When customizing aluminum profiles through surface finishing, there are several factors that need to be considered to achieve the desired results. These factors include:

- Design and Specifications: The design and specifications of the aluminum profile determine the type of surface finishing that can be used. It is essential to consider the shape, size, and intended use of the profile to choose the best surface finishing technique.

- Material selection: The material of the aluminum profile can also affect the choice of surface finishing. Different aluminum alloys have different chemical compositions, which can affect the surface finishing process and the final results.

- Environmental Factors: The intended use and environment of the aluminum profile should also be considered when choosing the surface finishing technique. Different techniques offer different levels of protection against environmental factors such as humidity, UV rays, and temperature changes.

- Cost and Budget: The cost of surface finishing can vary depending on the type of technique used, the size of the aluminum profile, and the level of customization required. It is essential to consider the cost and budget when choosing the surface finishing technique to avoid overspending.

3 Advantages of Partnering with a Reliable Aluminum Profiles Manufacturer

Partnering with a reliable aluminum profiles manufacturer can offer several advantages when customizing aluminum profiles. These advantages include:

- Expertise and Experience: A professional aluminum profiles manufacturer has the expertise and experience required to choose the best surface finishing technique for different aluminum profiles. They can provide recommendations based on the intended use, design, and environmental factors.

- Customization Options: A professional aluminum profiles manufacturer can offer a wide range of customization options, including different colors, textures, and finishes. They can also provide customized solutions to meet specific design and performance requirements.

- Quality Assurance: A professional aluminum profiles manufacturer has quality control measures in place to ensure that the finished product meets the required standards. They can also provide warranties and guarantees for their work, providing peace of mind to the customers.

Conclusion

Surface finishing customization of aluminum profiles offers several benefits, including enhanced aesthetics, improved corrosion resistance, durability, and wear resistance. Different surface finishing techniques can be used, including powder coating, anodizing, painting, and electrophoretic coating. When customizing aluminum profiles through surface finishing, factors such as design and specifications, material selection, environmental factors, and cost and budget should be considered. Partnering with a professional aluminum profiles manufacturer can offer expertise, customization options, and quality assurance. Overall, surface finishing customization is an essential aspect of aluminum profile customization that should not be overlooked.

Related Products

Related Articles