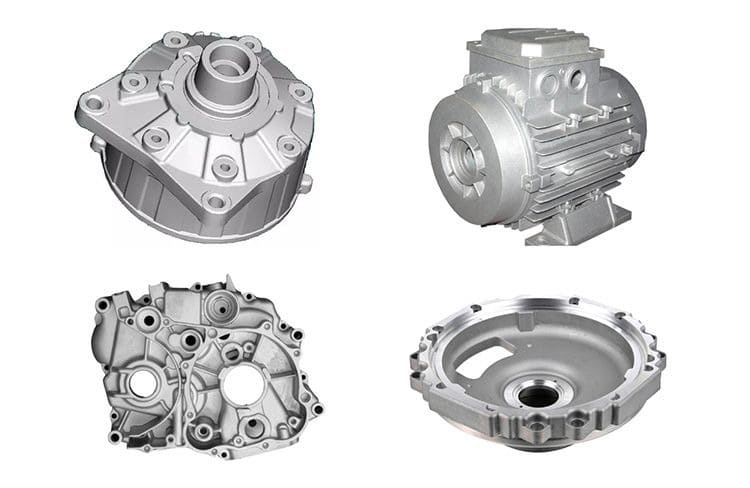

Aluminum die castings refer to equipment components made of pure aluminum or aluminum alloys obtained by casting. In general, heated liquid aluminum or aluminum alloy is poured into sand molds or metal molds, and the resultant aluminum parts or aluminum alloy components of various shapes and sizes are typically referred to as aluminum die castings. However, there are frequently a number of issues that arise during the processing and lead to part faults.

1. Occurrence and countermeasures of pores and air bubbles

Defect characteristics: The three Aluminum die castings‘ walls often have round or oval holes with a smooth surface, typically lustrous oxide skin, and occasionally greasy yellow. Sandblasting can be used to find surface pores and bubbles, while mechanical processing or X-ray vision can be used to find inside pores and bubbles. On the X-ray film, the pores and bubbles are visible as black.

cause:

1. Casting alloy is not stable, gas is involved.

2. The mold (core) sand is mixed with organic impurities (such as coal chips, grassroots, horse manure, etc.).

3. Poor ventilation of mold and sand core.

4. Shrinkage cavity on the cold iron surface.

5. Poor gating system design.

Prevention method:

1. Correctly grasp the pouring speed to avoid getting involved in gas.

2. The mold (core) shall not be mixed with organic impurities to reduce the gas generation of the molding material.

3. Improved venting capacity of (core) sand.

4. Proper selection and handling of cold iron.

5. Improved gating system design.

2. Occurrence and countermeasures of cracks

Defect characteristics:

1. Casting cracks. Developing along the grain boundary, often accompanied by segregation, is a kind of crack formed at a higher temperature, which is easy to appear in alloys with larger volume shrinkage and castings with more complex shapes.

2. Heat treatment cracks: Transgranular cracks are often caused by heat treatment overburning or overheating. It is often caused by excessive cooling of alloys with large stress and thermal expansion coefficient. or when other metallurgical defects exist.

cause:

1. The structure design of the casting is unreasonable, there are sharp corners, and the thickness of the wall varies greatly.

2. Sand mold (core) yield is poor.

3. Partial overheating of the mold.

4. Pouring temperature is too high.

5. Premature removal of casting from a mold.

6. Overheating or overheating in heat treatment, excessive cooling rate.

Prevention method:

1. Improve the structural design of Aluminum die castings, avoid sharp corners, and strive for uniform wall thickness, and smooth transition.

2. Take Measures to Increase Sand Mold (Core) Concession.

3. Ensure that all parts of the casting solidify simultaneously or sequentially, and improve the design of the gating system.

4. Appropriately reduce the pouring temperature.

5. Control mold cooling time.

6. The thermal correction method is used when the casting is deformed.

7. Correctly control the heat treatment temperature and reduce the quenching cooling rate.

3. Occurrence and countermeasures of oxidation slag inclusions

Defect characteristics: The majority of the oxidized slag inclusions are found in the unventilated mold corners on the casting’s upper surface. The fracture, which is mostly off-white or yellow, can be seen in X-ray images or when objects are processed mechanically. It can also be seen when objects are cleaned with alkali, pickled, or anodized.

cause:

1. Furnace charge is not clean, and too much recycling charge is used.

2. Poor gating system design.

3. The slag in the alloy liquid is not cleaned.

4. Improper pouring operation, bringing in slag inclusions.

5. Not enough standing time after refining and deterioration treatment.

Prevention method:

1. Furnace charges should be sand blown, and the amount of returned charges should be appropriately reduced.

2. Improve the gating system design and improve its slag-retaining ability.

3. Use appropriate flux to remove slag.

4. When pouring, it should be stable, and pay attention to slag blocking.

5. After refining, the alloy liquid should be allowed to stand for a certain period before pouring.

4. Occurrence and countermeasures of shrinkage porosity

Defect characteristics: Shrinkage porosity of Aluminum die castings generally occurs at the thick and large part of the root of the flying riser near the inner runner, the thickness transition of the wall, and the thin wall with a large plane. The fracture is gray in the cast state, and light yellow after heat treatment, it is grayish white light yellow or gray-black, and it is cloudy on the X-ray film. Severe filamentous shrinkage can be found by inspection methods such as X-ray and fluorescence low-magnification fracture.

cause:

1. Riser feeding effect is poor.

2. Too much gas in the charge.

3. Overheating near the gate.

4. The sand mold has too much moisture, and the sand core has not been dried.

5. Coarse Alloy Grain.

6. Improper position of the casting in the mold.

7. The pouring temperature is too high and the pouring speed is too fast.

Prevention method:

1. Replenishing molten metal from the riser to improve the design of the riser.

2. Charge should be clean and free from corrosion.

3. Riser is set at the shrinkage part of the casting, and the chilled iron is placed or used in combination with the chilled iron and riser.

4. Control sand moisture, and sand core drying.

5. Take measures to refine the grain.

6. Improve the position of the casting in the mold to reduce the pouring temperature and pouring speed.