With the rapidly growing demand of the lithium battery industry, lithium battery aluminum foil is used more and more popular. This article will introduce you to the battery aluminum foil comprehensively. If you want to know the demand for battery aluminum foil, you can click here.

What is battery aluminum foil?

Battery aluminum foil is used as a current collector for lithium-ion batteries. Typically, the lithium-ion battery industry uses rolled aluminum foil as the positive electrode current collector.

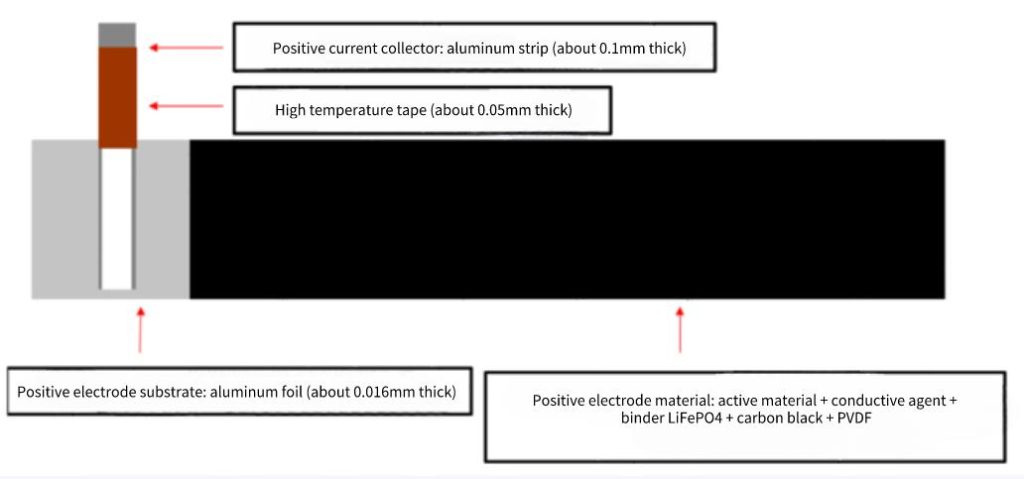

Battery aluminum foil (Aluminum foil for lithium-ion batteries) is divided into an aluminum foil for lithium battery positive current collector, aluminum foil for lithium battery outer packaging aluminum-plastic film, and aluminum foil for tabs. The commonly referred to as battery aluminum foil refers to the aluminum foil used for the positive electrode collector of lithium batteries. On the one hand, the positive electrode foil of the battery is the current collector electrode, and on the other hand, battery aluminum foil is the carrier of the positive electrode material of the lithium battery, that is, the lithium battery material should be coated on it.

Battery aluminum foil is an important raw material for lithium battery production. The positive electrode is composed of a positive electrode tab, high-temperature tape, the positive electrode current collector aluminum foil, and positive electrode material. The thickness of positive electrode current collector aluminum foil is generally 0.010mm-0.015mm. There are three main materials for aluminum foil for lithium batteries: positive pole piece, tab, and cladding material.

2 Types of battery aluminum foil

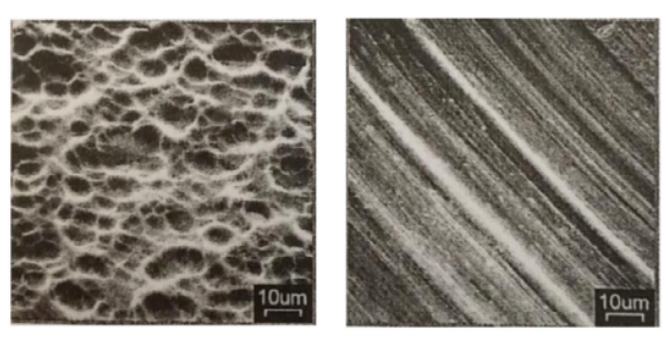

Lithium battery cathode aluminum foil (battery aluminum foil) has two types: flat and surface-modified aluminum foil. The feature of flat aluminum foil is high strength, high electrical conductivity, and high flatness. The feature of surface-modified foil has greatly improved the adhesion of active materials due to the roughened surface and can reduce the number of adhesives and improve battery characteristics.

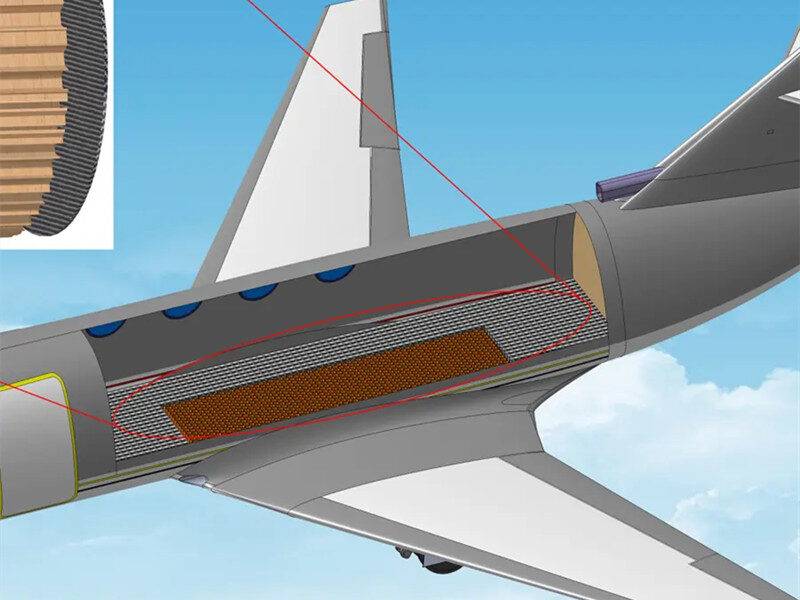

Battery aluminum foil uses

Positive current collector aluminum foil is used in ternary batteries, lithium iron phosphate batteries, sodium-ion batteries, etc.

5 Battery aluminum foil performance requirements

Thickness requirements of battery aluminum foil: The thinnest thickness of battery foil has reached 8μm. The thickness deviation is required to be small, generally within ±4%, and individual battery manufacturers require within ±2%.

Surface quality requirements of battery aluminum foil: Pitting spots with a diameter greater than 1mm are not allowed on the surface. Pitting spots with a diameter of 0.5mm~1mm should be less than 3/m2. Besides, there must be no bumps or bright spots on the dark side.

Surface wetting tension requirements of battery aluminum foil: General users require surface wetting tension between 30-32dyn, but some sensitive materials require higher dyne value.

Trimming quality requirements of battery aluminum foil: The trimming quality of the battery aluminum foil should be high without cracks and burrs.

Battery aluminum foil requirements for mechanical properties: While thinning, the tensile strength Rm must be increased simultaneously, otherwise, the bursting strength cannot meet the requirements of battery aluminum foil. In industry, the work hardening limit of pure aluminum is 310N/mm2, and the tensile strength of battery aluminum foil is mostly between 190-280N/mm2.

The advantages of battery aluminum foil

The advantages of aluminum foil applied to lithium-ion batteries are in the following aspects:

1. Battery aluminum foil extends the service life of lithium-ion batteries because the special aluminum foil has better physical properties, which significantly improves the cycle performance of lithium-ion batteries.

2. To improve the consistency of lithium-ion batteries, the use of special aluminum foil can not only reduce the internal resistance but also improve the consistency of internal resistance.

3. Battery aluminum foil Improves the rate discharge performance of the battery. After the special aluminum foil is selected, the rate performance of the lithium-ion battery is significantly improved. Especially, in the case of a large rate (greater than 3C), the rate discharge capacity is improved by more than 15%, or at the same rate. In this case, special aluminum foil can improve the energy density of lithium-ion batteries. To know more about battery aluminum, you can click here.