Aluminum Discs Circles: A Versatile and Durable Material with a Wide Range of Applications

Aluminum discs circles are flat, round or shaped pieces of aluminum that are used in a variety of applications. They are made from high-quality aluminum alloy that is lightweight, strong, and corrosion-resistant…

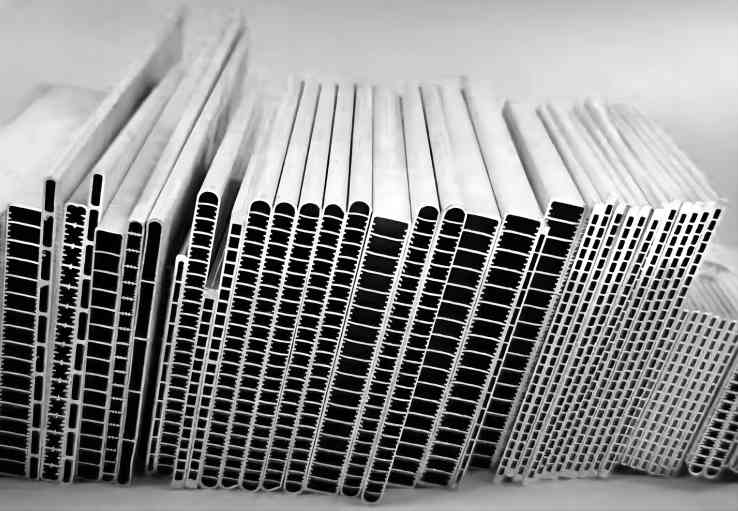

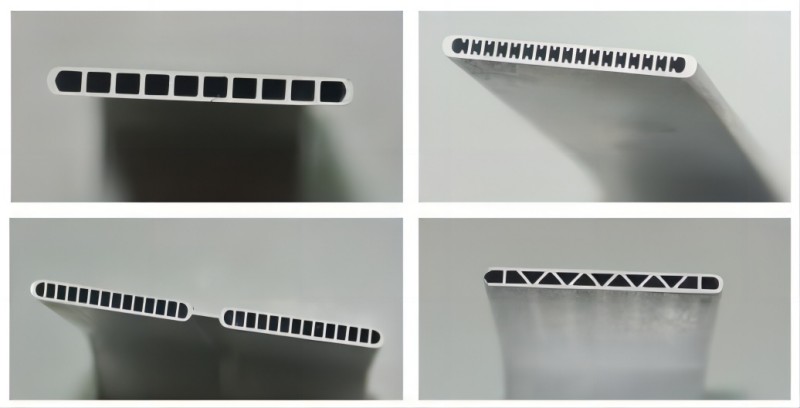

What are the Safety Considerations for Working with Aluminum Multi-Port Extrusions?

Aluminum multi-port extrusions are versatile components used in various industries, such as automotive, HVAC (Heating, Ventilation, and Air Conditioning), and refrigeration. The most common multi-port extrusion is an MPE tube. They…

The Smart Choice for Industry: T-Slot Aluminum Framing in Manufacturing and Automation

In the fast-paced world of modern industry, efficiency, flexibility, and precision are paramount. Manufacturers and automation engineers are constantly seeking innovative solutions to meet the ever-increasing demands of production while…

Drawn Aluminum Tube: A Versatile Material with a Wide Range of Applications

Drawn aluminum tube is a type of aluminum tubing that is made by drawing a solid aluminum billet through a die. This process is also known as cold drawing. The billet is first heated…

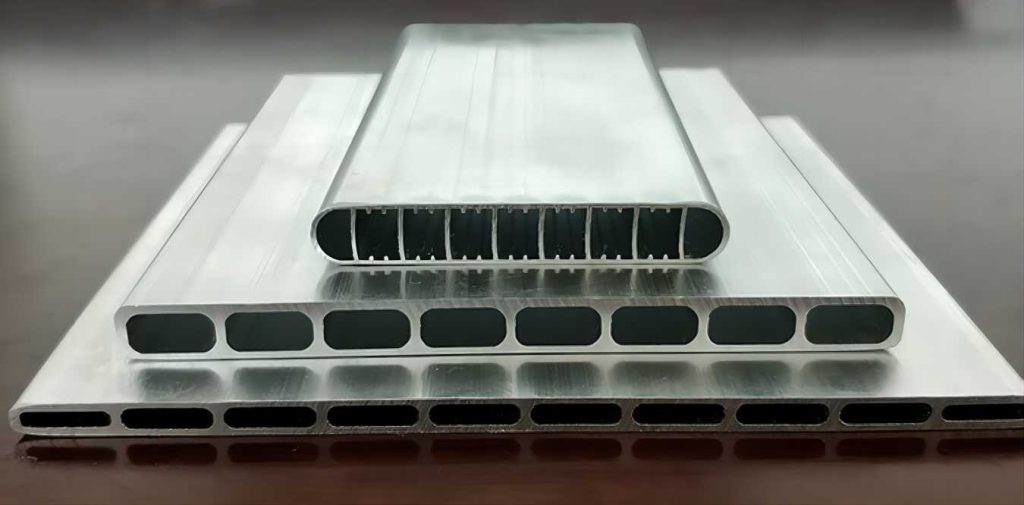

What are the Different Types of Fittings Used with Aluminum Multi-Channel Tubes?

Aluminum multi-channel tubes, also known as MPE tubes (Multi Port Extrusion) or multiport extruded aluminium tubes, are essential components in various industries, particularly in the manufacturing of heat exchangers, condenser coils,…

Aluminum Microchannel Tubes and Aluminum Multi-Channel Tubes: A Path to Efficient Heat Transfer

Aluminum microchannel tubes and aluminum multi-channel tubes are a type of heat exchanger that uses a network of small channels to transfer heat from one fluid to another. These tubes are made…

T-Slot Aluminum: A Versatile Solution for Modern Construction and Design

In the world of modern engineering and construction, T-slot aluminum has emerged as a game-changer. This versatile material, also known as T-slot aluminum extrusion or T-channel aluminum, offers engineers, designers, and hobbyists…

5052 vs 6061 Aluminum Sheet: Which is Right for You?

Aluminum sheets are a versatile material that is used in a wide variety of applications. Two of the most common aluminum alloys are 5052 and 6061. These alloys have different properties, so…

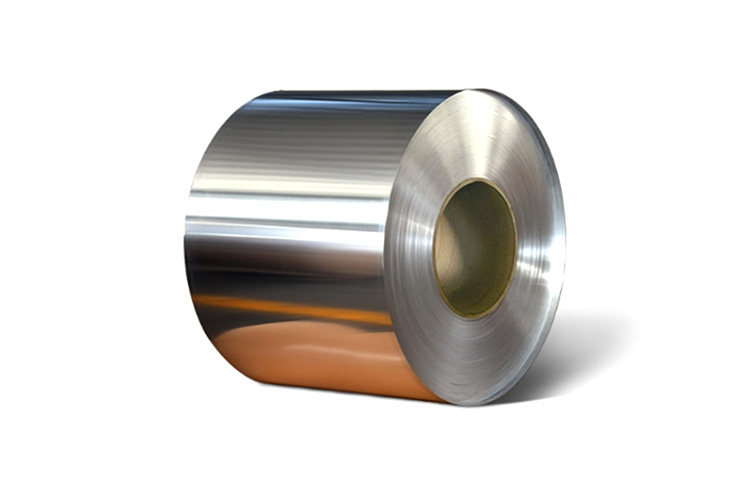

The Properties of Aluminum Strip

Aluminum strip is a versatile material with a wide range of properties. It is lightweight, corrosion-resistant, easy to form, and has good electrical and thermal conductivity. These properties make it a…

The Superiority of Alumina Fiber: A Comprehensive Comparative Analysis with Other Fibers

Fiber materials play a crucial role in various industries, where high-temperature resistance, thermal stability, and mechanical strength are paramount. Alumina fiber, a type of ceramic fiber, has gained significant attention due…

The Differences Between Extruded and Seamless Aluminum Tubes

Aluminum tubes are a versatile and widely used material in a variety of applications. They are strong, lightweight, and corrosion-resistant, making them ideal for use in a wide range of environments. There…

What are the Advantages and Disadvantages of Using Aluminum Condenser Header Pipe?

Aluminum condenser header pipes have become a popular choice in refrigeration and air conditioning systems due to their unique properties and performance characteristics. These essential components play a vital role in…