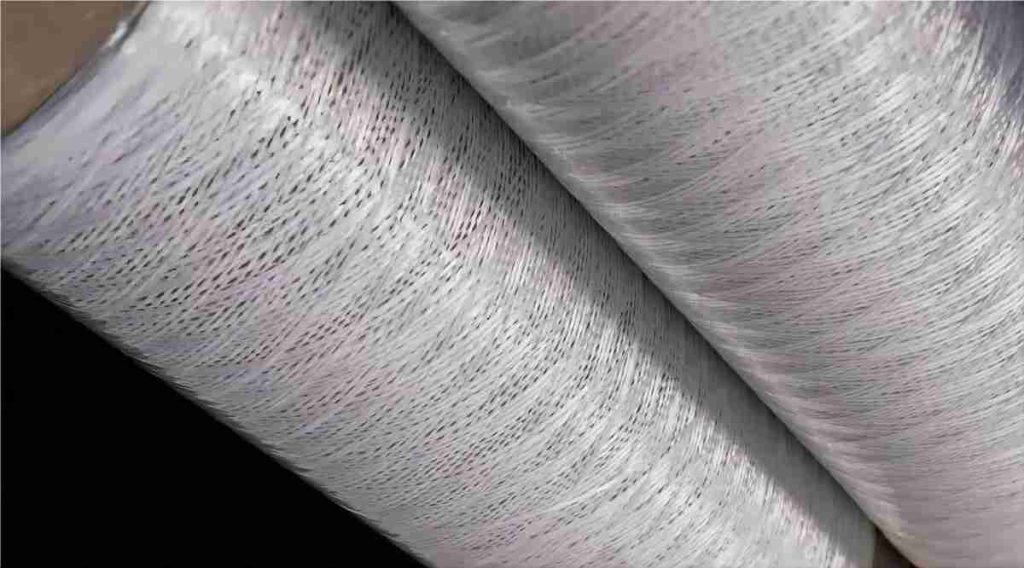

Fiber materials play a crucial role in various industries, where high-temperature resistance, thermal stability, and mechanical strength are paramount. Alumina fiber, a type of ceramic fiber, has gained significant attention due to its exceptional properties. In this article, we will delve into the world of alumina fiber and compare it with other fibers in terms of properties, applications, suitability, and cost considerations.

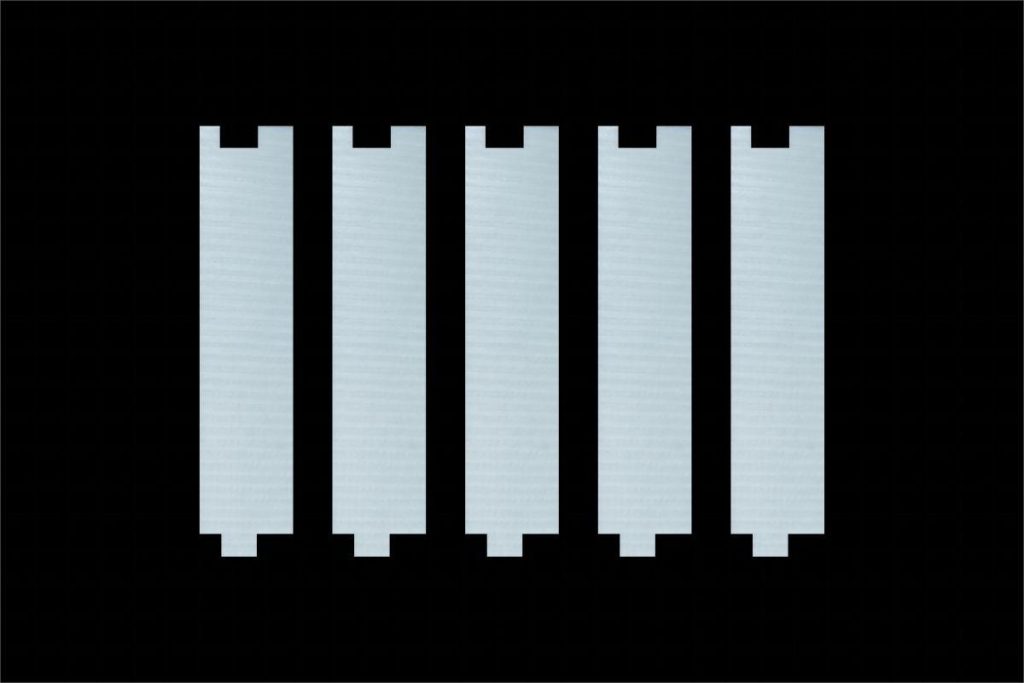

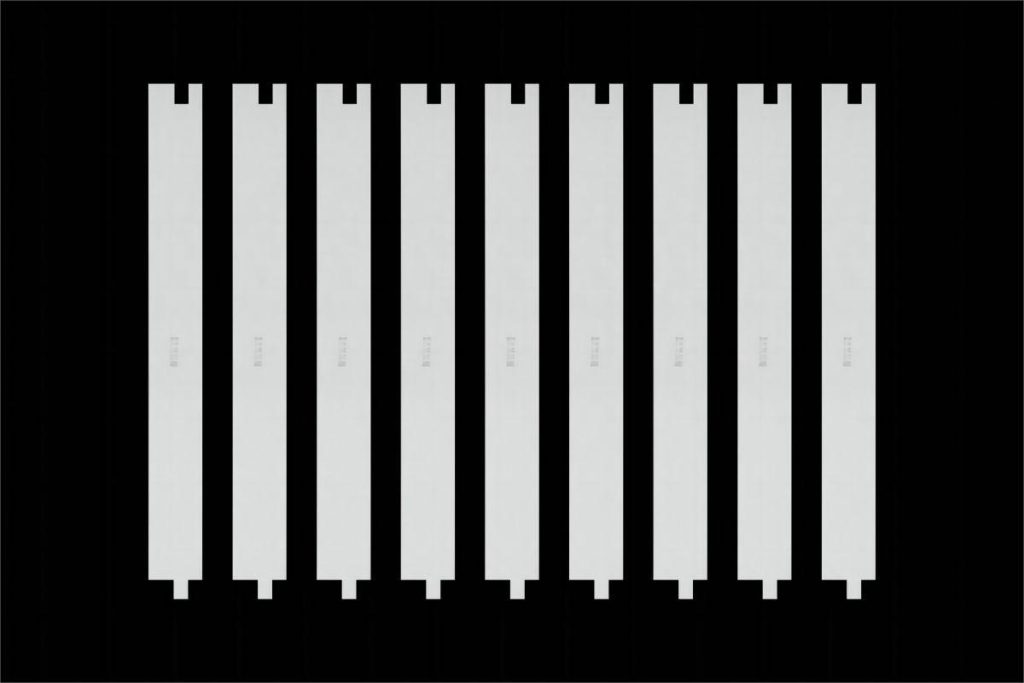

What Is Alumina Fiber?

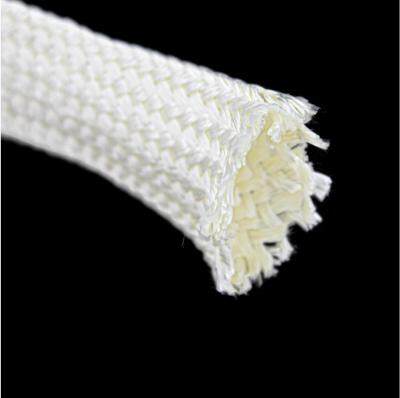

Alumina fiber, also known as aluminum oxide fiber, is a ceramic material that possesses several remarkable characteristics. It boasts high-temperature resistance, making it suitable for use in extreme heat environments. Additionally, alumina fiber demonstrates exceptional thermal stability, maintaining its structure and properties even at elevated temperatures. Its high mechanical strength and chemical inertness further enhance its versatility. Moreover, alumina fiber exhibits excellent electrical insulation properties, making it valuable in applications where electrical conductivity must be minimized.

Comparison with Other Ceramic Fibers

Compared with Silicon Carbide Fiber

Silicon carbide fiber shares some similarities with alumina fiber, particularly in high-temperature resistance and mechanical strength. It is commonly used in the aerospace and automotive industries, as well as in chemical processing. However, silicon carbide fiber has a higher thermal conductivity than alumina fiber, which may limit its suitability in certain insulation applications. Alumina fiber, on the other hand, offers better chemical inertness, making it more resistant to corrosive environments.

Compared with Zirconia Fiber

Zirconia fiber possesses excellent thermal stability and chemical resistance, similar to alumina fiber. However, zirconia fiber is more prone to embrittlement at high temperatures, limiting its usage in extreme heat conditions compared to alumina fiber. Alumina fiber, with its superior mechanical strength, may be preferred in applications requiring robust and reliable performance.

Compared with Mullite Fiber

Mullite fiber shares some similarities with alumina fiber, as both materials are derived from aluminum and silica-based precursors. Mullite fiber exhibits good thermal shock resistance, which may outperform alumina fiber in certain rapid temperature change scenarios. However, alumina fiber’s higher melting point and mechanical strength make it more suitable for use in extremely high-temperature environments.

Comparison with Traditional Fibers

Compared with Glass Fiber

Glass fiber is widely used for its low cost and good electrical insulation properties. However, when compared to alumina fiber, glass fiber has significantly lower thermal stability and mechanical strength. Alumina fiber provides an excellent alternative for applications requiring resistance to high temperatures and demanding mechanical conditions.

Compared with Carbon Fiber

Carbon fiber is renowned for its outstanding strength-to-weight ratio, making it ideal for lightweight structural applications. However, carbon fiber is susceptible to oxidation at high temperatures, which may limit its usage in certain high-temperature environments. Alumina fiber’s ability to withstand elevated temperatures without significant degradation makes it a preferred choice for extreme heat applications.

Specific Applications and Suitability

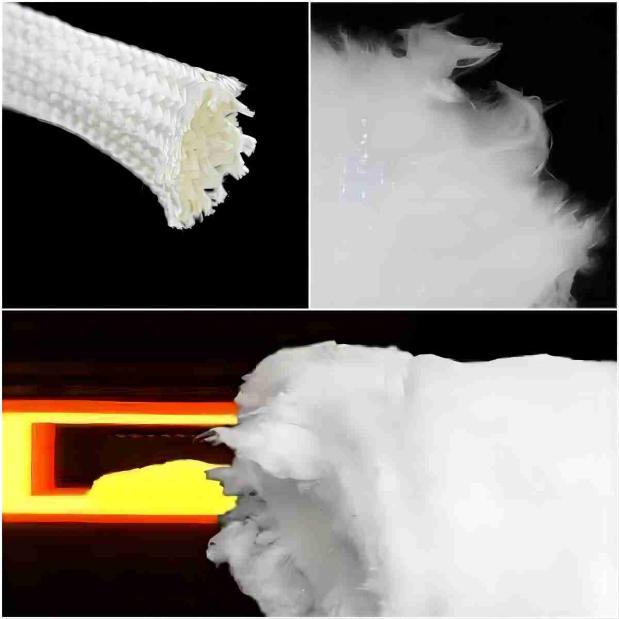

- Aerospace Industry: In the aerospace industry, alumina fiber finds use in engine components, thermal protection systems, and aircraft brakes. Its high-temperature resistance and mechanical strength make it invaluable in these critical applications, ensuring reliable performance even in extreme conditions.

- Automotive Industry: Alumina fiber is utilized in the automotive industry for exhaust system components, brake pads, and thermal insulation. Its ability to withstand the high temperatures generated by combustion engines and braking systems contributes to improved durability and safety.

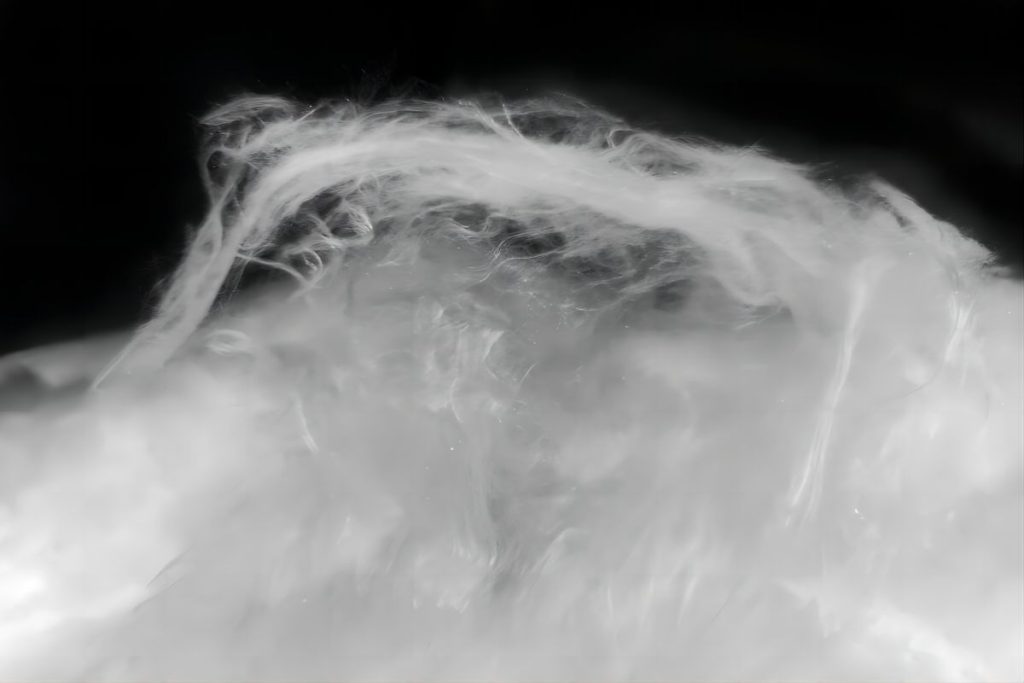

- High-Temperature Insulation: Alumina fiber is an excellent thermal insulator, finding application in kilns, furnaces, and heat shields. Its thermal stability and insulation properties help maintain high temperatures efficiently and prevent heat loss.

- Chemical Processing: In chemical processing, alumina fiber is employed in lining reactors, furnaces, and other equipment exposed to corrosive substances and high temperatures. Its chemical inertness ensures stability and longevity in harsh chemical environments.

- Electrical Insulation: The electrical insulation properties of alumina fiber make it suitable for electrical components, such as insulators and protective covers, where electrical conductivity must be minimized.

Cost Considerations

Alumina fiber generally falls within the mid to high price range among ceramic fibers. Although it may be more expensive than some traditional fibers like glass fiber, its superior properties and performance in high-temperature environments often justify the investment. The long-term cost-effectiveness of alumina fiber must be assessed based on the specific application and its intended lifespan.

Health and Safety Considerations

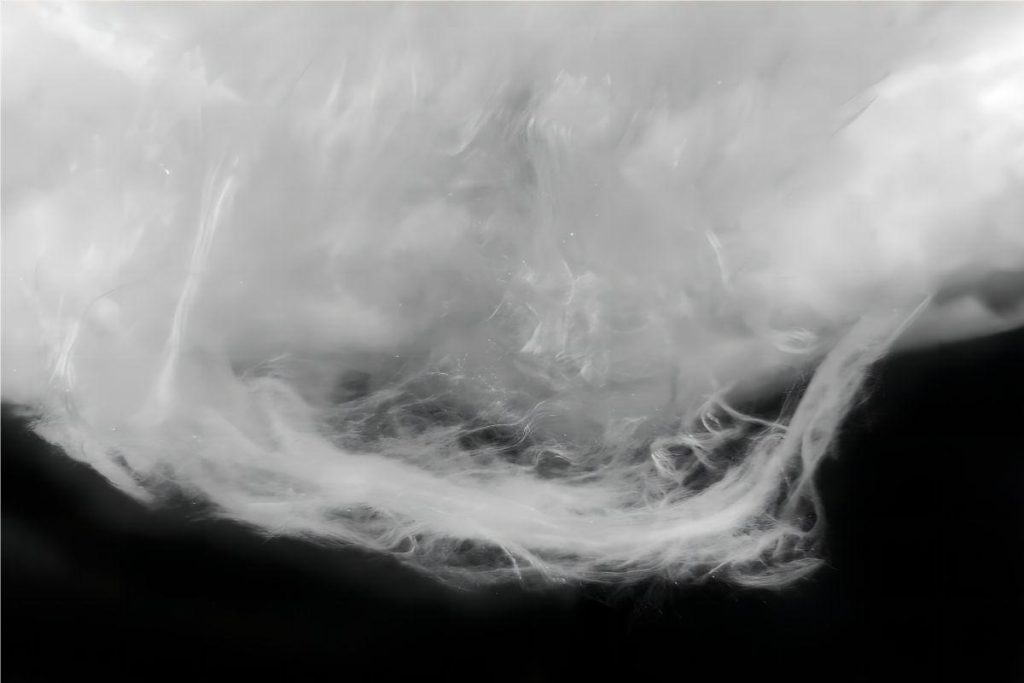

Alumina fiber, like other ceramic fibers, can pose health risks if its dust or fibers are inhaled. Proper handling, storage, and use are essential to minimize exposure. Users should follow safety guidelines and wear appropriate personal protective equipment when working with alumina fiber.

Conclusion

Alumina fiber stands out as a remarkable ceramic material, offering high-temperature resistance, thermal stability, mechanical strength, and excellent electrical insulation properties. In comparison with other fibers, it presents a favorable balance of characteristics that make it valuable across various industries. Its applications in aerospace, automotive, chemical processing, and insulation demonstrate its versatility and importance in modern technology and engineering. As industries continue to seek materials that can withstand demanding conditions, alumina fiber will likely remain a key contender for high-performance applications.