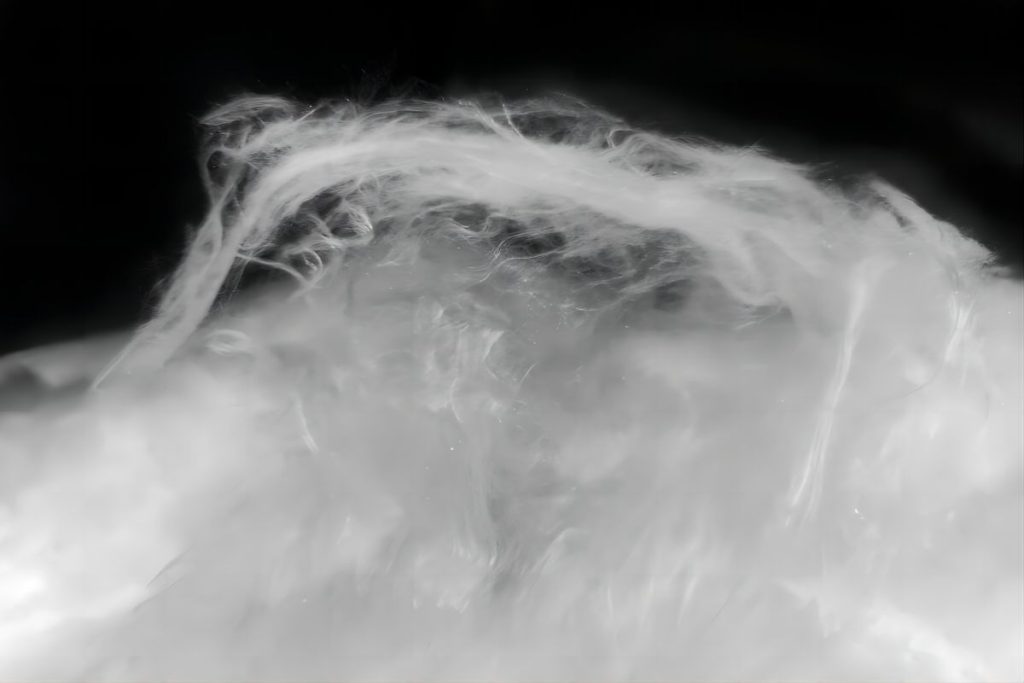

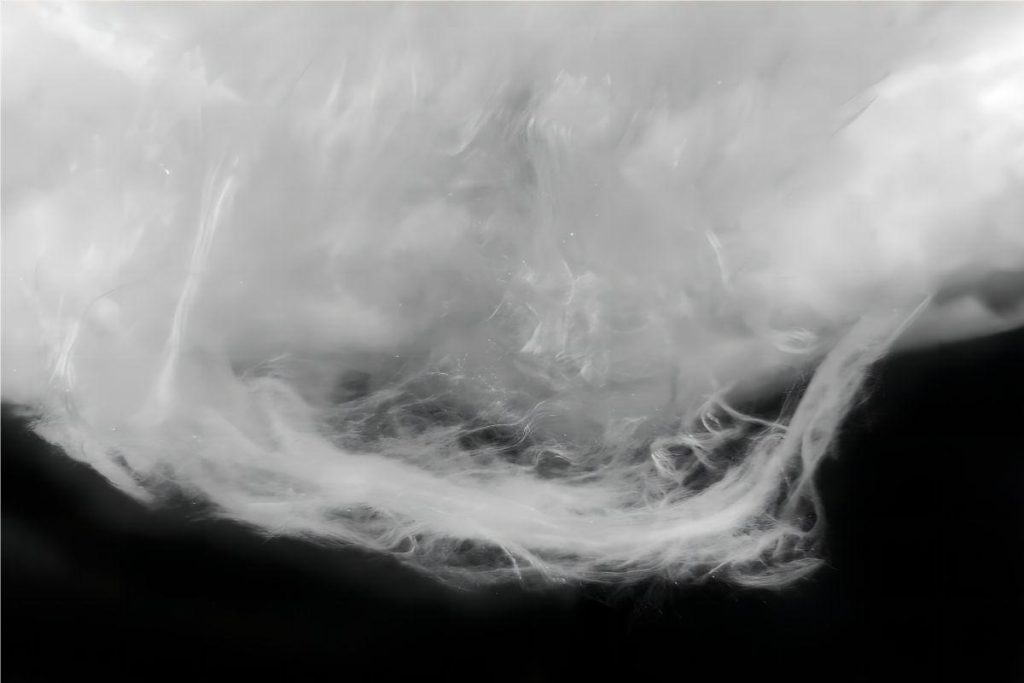

Alumina fiber, also known as aluminum oxide fiber, is a high-performance ceramic fiber made from aluminum oxide. It is a white, non-conductive material with excellent thermal and chemical stability. Alumina fiber has a melting point of 2,024°C (3673°F) and can withstand continuous temperatures of up to 1,300°C (2372°F). It is also resistant to corrosion by most chemicals. In this article, we will discuss the alumina fiber’s applications, properties and future trends.

Alumina fiber is used in a wide variety of applications, including:

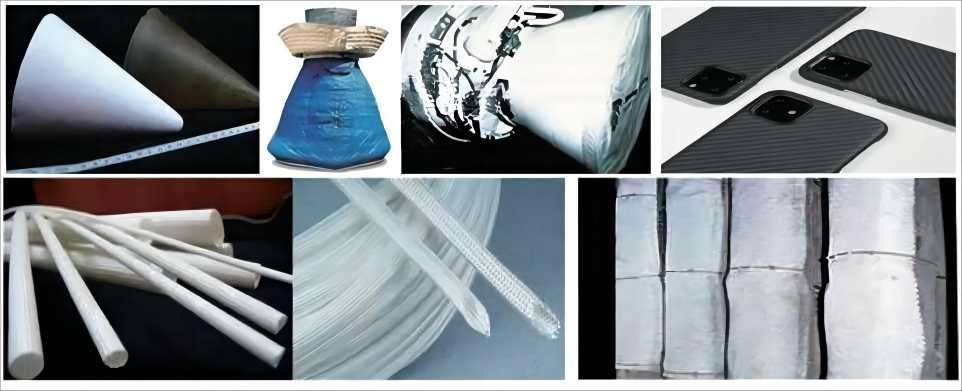

- Composite materials: Alumina fiber is frequently employed to fabricate composite materials. These materials are formed by blending two or more substances to create a material with desired characteristics. Alumina fiber is typically incorporated into composite materials to enhance strength and rigidity.

- Reinforcement for concrete: Alumina fiber serves as a reinforcement material for concrete, augmenting its strength and resistance against cracking.

- Electrical insulation: Alumina fiber proves valuable as an electrical insulator. While it conducts electricity effectively, its resistance to corrosion makes it an ideal choice for applications requiring electrical insulation.

- Heat shields: Alumina fiber finds application in heat shields, acting as a protective barrier against high temperatures. Its resistance to extreme heat and lightweight nature makes it an optimal selection for heat shield applications.

- Wear-resistant components: Alumina fiber is instrumental in the production of wear-resistant components. These components are essential in settings characterized by significant friction. The strength and durability of alumina fiber make it an excellent choice for wear-resistant components.

- Filtration: Alumina fiber is highly suitable for filtration applications. The fibers are spun into fabrics that effectively filter out particles from liquids or gases.

- Aerospace: Alumina fiber plays a vital role in numerous aerospace applications, including heat shields, thermal insulation, and reinforcement for composites.

- Chemical processing: Alumina fiber finds utilization in chemical processing, such as filters, pumps, and valves.

- Medical: In the medical field, alumina fiber is employed in diverse applications, such as bone implants and artificial joints.

The properties of alumina fiber make it a versatile material with a wide range of applications. It is lightweight, strong, corrosion-resistant, and has good electrical and thermal conductivity. These properties make alumina fiber a good choice for a variety of applications, including composite materials, reinforcement for concrete, electrical insulation, heat shields, and wear-resistant components.

Properties of Alumina Fiber

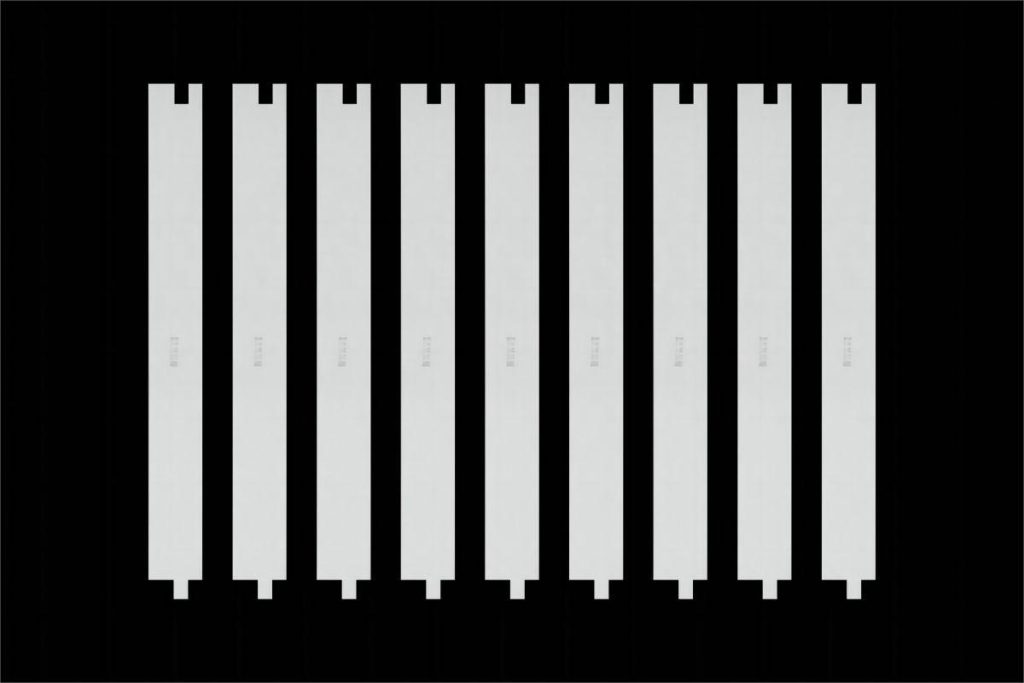

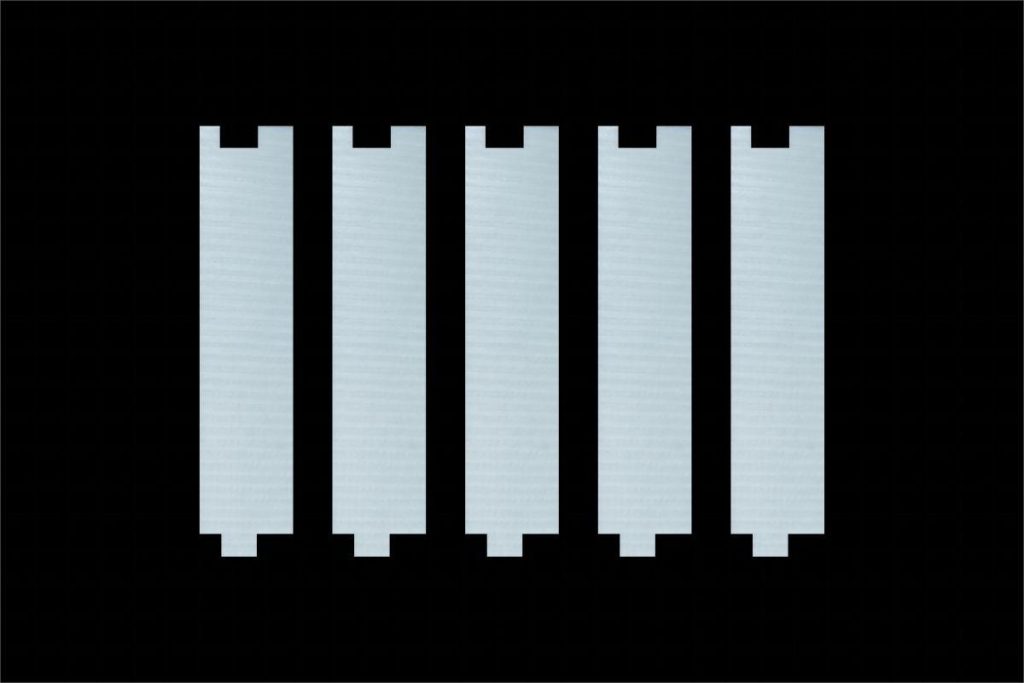

The properties of alumina fiber vary depending on the manufacturing process and the type of aluminum used. However, in general, alumina fiber has the following properties:

- Density: Alumina fiber has a density of about 3.9 g/cm3, which is about twice the density of steel. This makes alumina fiber a relatively heavy material.

- Melting point: The melting point of alumina fiber is about 2,024°C (3673°F). This means that alumina fiber can withstand high temperatures without melting.

- Electrical conductivity: Alumina fiber is a good conductor of electricity. It has an electrical conductivity that is about 10% of that of copper.

- Thermal conductivity: Alumina fiber is a good conductor of heat. It has a thermal conductivity that is about twice that of steel.

- Corrosion resistance: Alumina fiber showcases a high resistance to corrosion from the majority of chemicals. This makes it an exceptional choice for applications that demand corrosion-resistant materials.

- Oxidation resistance: Alumina fiber is resistant to oxidation. This means that it can withstand high temperatures without oxidizing.

- Strength: Alumina fiber is strong. It has a tensile strength that is about 2,000 MPa.

- Stiffness: With a modulus of elasticity measuring around 370 GPa, alumina fiber possesses remarkable stiffness.

- Toughness: Alumina fiber is characterized by high impact strength, indicating its ability to withstand substantial force.

Future Trends

The use of alumina fiber is expected to grow in the future. This is because alumina fiber is a lightweight, strong, corrosion-resistant material with a wide range of applications. As the demand for these properties increases, the use of alumina fiber is expected to grow.

Some of the specific trends that are expected to drive the growth of the alumina fiber market include:

- Increasing demand for lightweight materials: Industries such as automotive and aerospace are increasingly seeking lightweight materials to enhance fuel efficiency and performance. Alumina fiber, with its lightweight nature, is well-positioned to fulfill these requirements.

- Growing demand for corrosion-resistant materials: Chemical and industrial processing industries place a premium on materials that can withstand corrosive environments. Alumina fiber’s exceptional resistance to corrosion positions it as an ideal choice for such applications.

- Rising demand for electrical insulation materials: The electronics and electrical industries require effective electrical insulation materials. Alumina fiber’s impressive electrical insulation capabilities make it an attractive option for these sectors.

Overall, the future of alumina fiber looks bright. The demand for this versatile material is expected to grow in the coming years, driven by the need for lightweight, strong, and corrosion-resistant materials in a variety of industries.

Conclusion

Alumina fiber is a versatile and high-performance material with a wide range of applications. It is lightweight, strong, corrosion-resistant, and has good electrical and thermal conductivity. These properties make alumina fiber a good choice for a variety of applications, including composite materials, reinforcement for concrete, electrical insulation, heat shields, and wear-resistant components.

The use of alumina fiber is expected to grow in the future. This is due to the fact that alumina fiber is a lightweight, strong, corrosion-resistant material that has a wide range of applications. As the demand for these properties increases, the use of alumina fiber is expected to grow. If you are looking for an alumina fiber supplier, contact us, and you’ll be served professionally and find what you want.