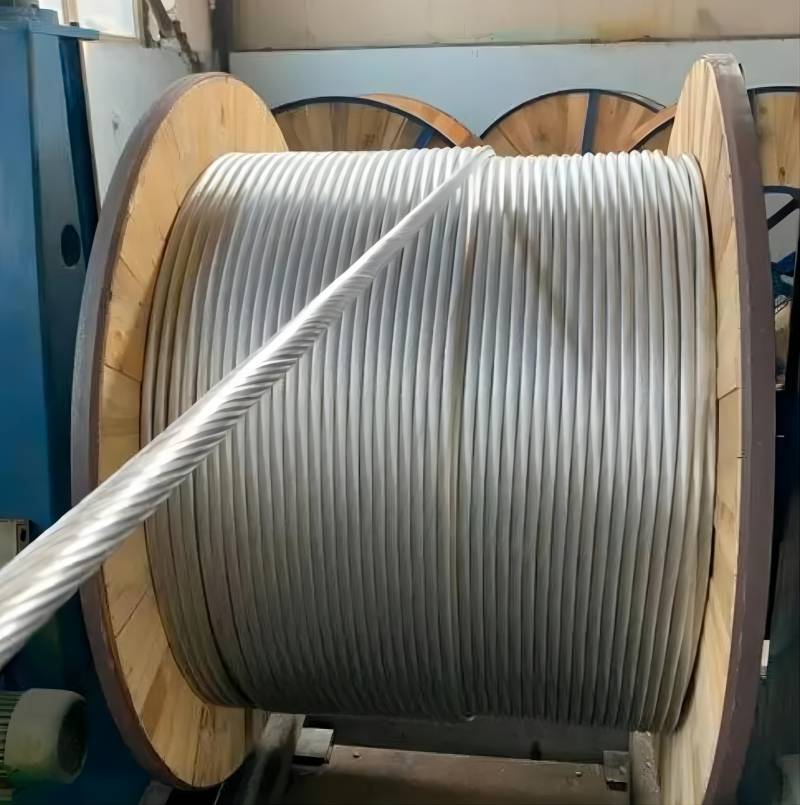

Power transmission lines are the lifelines of modern society, facilitating the transfer of electricity from generation sources to homes, businesses, and industries. At the heart of these sprawling networks lies a crucial component: bare aluminum wire. In this article, we delve into the significance of bare aluminum wire in power transmission lines, exploring its role, advantages, applications, and maintenance practices.

What are the Power Transmission Lines?

Power transmission lines are the high-voltage cables that carry electricity over long distances, typically from power generation plants to substations. These substations then reduce the voltage for distribution lines that reach our neighborhoods and buildings.

Power transmission systems consist of several key components:

- Power Plants: Where electricity is generated, using various methods like fossil fuels, hydroelectric, nuclear, or solar.

- Generators: These convert mechanical energy into electrical energy.

- Transformers: Increase the voltage for efficient long-distance transmission.

- Transmission Lines: Our focus, the high-voltage lines carrying electricity.

- Substations: Reduce the voltage for distribution through transformers.

- Distribution Lines: Lower voltage lines that deliver electricity to end users.

Why Use Bare Aluminum Wire in Power Transmission Lines?

Bare aluminum wire is extensively utilized in power transmission lines due to several compelling reasons:

- Cost-effectiveness: Aluminum is abundantly available and less expensive than copper, the alternative material for conductors. This cost advantage makes bare aluminum wire a practical choice for constructing extensive transmission networks, especially over long distances where material costs can significantly impact project budgets.

- Lightweight: Aluminum is much lighter than copper, offering a high strength-to-weight ratio. This property makes it easier and more cost-effective to transport and install aluminum conductors, particularly in overhead transmission lines spanning vast geographical areas.

- Excellent conductivity: While aluminum’s conductivity is lower than that of copper, it is still sufficiently high for efficient electricity transmission. Advances in aluminum alloy formulations and conductor designs have further enhanced its conductivity, allowing for the economical transmission of electricity over long distances with minimal line losses.

- Durability: Bare aluminum wire exhibits excellent resistance to corrosion, making it suitable for use in various environmental conditions, including coastal regions and areas with high humidity or pollution levels. This durability ensures the longevity of transmission lines, reducing the need for frequent replacements and maintenance interventions.

- Compatibility with overhead transmission: Aluminum’s lightweight nature and strength make it ideal for overhead transmission lines supported by towers or poles. Its ability to withstand mechanical stresses, such as wind and ice loads, contributes to the stability and reliability of overhead transmission infrastructure.

- Environmental considerations: Aluminum is a highly recyclable material, offering environmental benefits compared to other conductor materials. The recyclability of aluminum reduces the need for primary resource extraction and minimizes the environmental footprint associated with power transmission infrastructure projects.

Overall, the combination of cost-effectiveness, conductivity, durability, and environmental sustainability makes bare aluminum wire a preferred choice for power transmission lines, meeting the demands of modern energy infrastructure while balancing economic and environmental considerations.

Applications of Bare Aluminum Wire in Power Transmission

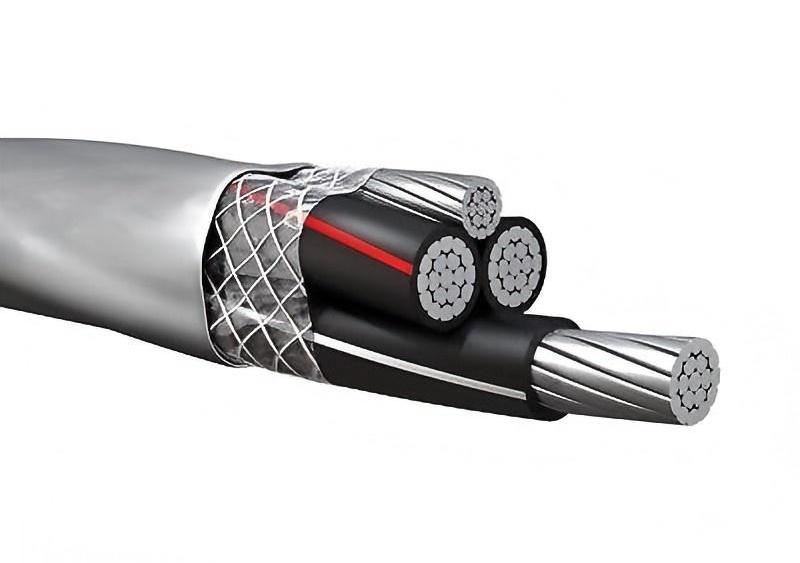

Bare aluminum wire finds diverse applications in power transmission, playing a vital role in facilitating the efficient and reliable transfer of electricity across vast distances. Some of the key applications include:

1. Overhead Transmission Lines:

Bare aluminum wire is extensively used as the primary conductor in overhead transmission lines. These lines typically stretch across long distances, connecting power generation facilities to substations and distribution networks. The lightweight nature of aluminum makes it well-suited for supporting overhead conductors on transmission towers or utility poles, reducing the structural requirements and costs associated with tower construction.

2. High-Voltage Direct Current (HVDC) Transmission:

In HVDC transmission systems, bare aluminum wire is employed to carry high-voltage direct current over long distances with minimal losses. HVDC technology is often utilized for interconnecting regional power grids, transmitting electricity between distant locations, and integrating renewable energy sources into the grid. Aluminum’s excellent conductivity and strength make it an ideal choice for HVDC transmission lines, enabling efficient and reliable long-distance power transmission.

3. Submarine Cables:

Bare aluminum wire is utilized in submarine power cables for transmitting electricity across bodies of water, such as seas and oceans. These submarine cables play a crucial role in connecting offshore wind farms, offshore oil and gas platforms, and island grids to mainland power systems. Aluminum’s corrosion resistance and durability make it well-suited for withstanding the harsh marine environment encountered by submarine power cables.

4. Railway Electrification:

Aluminum wire is commonly used in overhead catenary systems for railway electrification, providing power to electric trains and trams. These overhead catenary systems consist of bare aluminum conductors suspended above railway tracks, supplying electricity to trains through pantographs or overhead wires. Aluminum’s lightweight and conductivity properties make it an efficient choice for railway electrification, supporting sustainable and energy-efficient transportation solutions.

5. Distributed Generation and Microgrids:

In distributed generation systems and microgrids, bare aluminum wire may be employed for interconnecting distributed energy resources, such as solar photovoltaic arrays, wind turbines, and energy storage systems. These systems enable localized generation and distribution of electricity, enhancing grid resilience and supporting renewable energy integration. Aluminum wire facilitates the interconnection of distributed energy resources, enabling the efficient exchange of power within microgrid networks.

Overall, bare aluminum wire serves a diverse range of applications in power transmission, contributing to the reliability, efficiency, and sustainability of electricity infrastructure worldwide. Its versatility, conductivity, and durability make it an indispensable component in modern power transmission systems, meeting the evolving needs of the energy industry.

Installation and Maintenance

Installing and maintaining bare aluminum wire in power transmission lines requires careful planning, attention to detail, and adherence to industry standards and best practices. Here are the key steps involved in the installation and maintenance of bare aluminum wire:

Preparation and Planning:

- Conduct a thorough site survey to assess the terrain, environmental conditions, and route feasibility.

- Develop a comprehensive installation plan, considering factors such as conductor tension, sag, clearance requirements, and structural support for towers or poles.

- Obtain necessary permits and approvals from relevant regulatory authorities and landowners.

Installation:

- Clear the right-of-way and prepare the terrain for tower or pole installation.

- Erect transmission towers or poles at designated intervals along the route, ensuring structural integrity and compliance with safety standards.

- String bare aluminum conductors between towers or poles using specialized equipment such as tensioners, pullers, and helicopters for aerial installation.

- Maintain proper tension and sag of the conductors to prevent excessive stress and ensure adequate clearance from obstacles, vegetation, and ground surfaces.

- Install vibration dampers, spacers, and other accessories to minimize conductor movement and mitigate the risk of galloping or oscillation in windy conditions.

- Implement bonding and grounding measures to protect against lightning strikes and electrical faults.

Inspection and Testing:

- Conduct visual inspections of the transmission line periodically to identify signs of wear, corrosion, or damage to the bare aluminum conductors.

- Perform routine electrical tests, including impedance measurements, insulation resistance tests, and thermographic surveys, to assess the condition and performance of the transmission line.

- Utilize advanced inspection technologies such as drones, LiDAR, and thermal imaging to detect potential issues and anomalies along the transmission route.

Maintenance:

- Schedule regular maintenance activities, including conductor cleaning, vegetation management, and corrosion protection measures.

- Clear vegetation and debris from the right-of-way to prevent interference with the transmission line and minimize the risk of outages caused by falling branches or vegetation.

- Apply corrosion-resistant coatings or inhibitors to protect bare aluminum conductors from environmental degradation and extend their service life.

- Conduct repairs or replacements as needed to address damage or deterioration observed during inspections.

By following these guidelines and implementing a proactive approach to installation and maintenance, stakeholders can ensure the reliability, safety, and longevity of bare aluminum wire in power transmission lines. Regular inspections, preventive maintenance measures, and timely repairs are essential for optimizing the performance and resilience of transmission infrastructure, ultimately supporting the efficient delivery of electricity to consumers.

Conclusion

Bare aluminum wire plays a pivotal role in the functioning of power transmission lines, offering a balance of cost-effectiveness, conductivity, and durability. Its widespread adoption underscores its importance in meeting the growing demand for electricity transmission infrastructure worldwide. As the energy landscape continues to evolve, leveraging advancements in materials, construction techniques, and maintenance practices will be essential for enhancing the efficiency and resilience of power transmission systems. By recognizing the significance of bare aluminum wire and prioritizing its proper utilization and upkeep, you can contribute to the sustainability and reliability of the global electricity grid.